Introduction

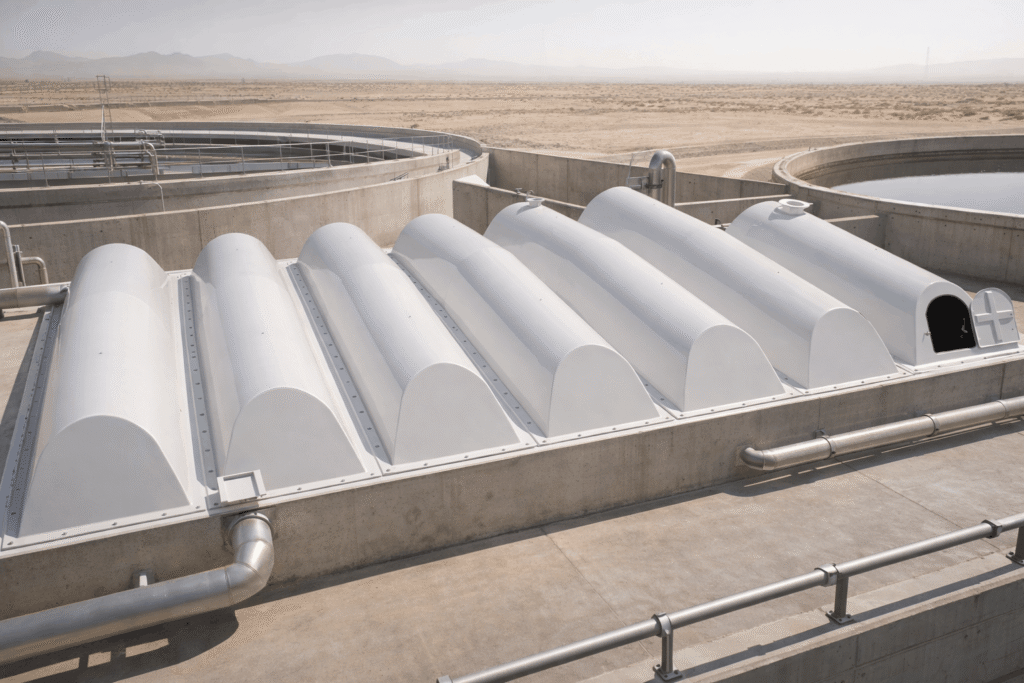

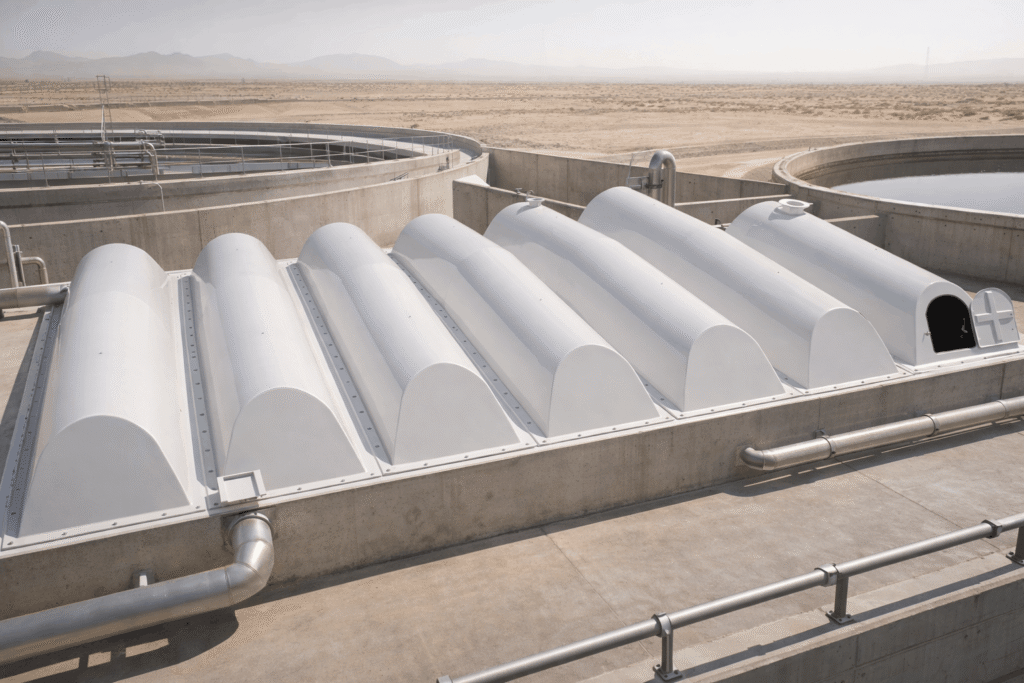

Wastewater treatment and sewage treatment facilities in Saudi Arabia face extreme heat, strong UV exposure, dust, coastal salinity, and often high hydrogen sulfide (H₂S) levels. These conditions increase odor complaints near nearby communities and accelerate corrosion of concrete and steel assets in tanks, channels, and headworks areas. GRP (glass reinforced plastic) covers are widely used as part of a broader odor control and infrastructure protection strategy, helping contain foul air, reduce corrosion risk, and improve long-term plant reliability. In this article, you will learn where GRP covers provide the most value, how to specify them correctly for KSA/GCC conditions, and the most common mistakes to avoid.

Quick Answer

- GRP covers for STP Saudi Arabia should be treated as process equipment, not architectural cladding, with clear performance and access requirements defined by the odor control designer and client/AHJ specs.

- They help confine odorous air from high H₂S zones so that WWTP odor control covers can be ventilated to treatment systems, while also shielding concrete and steel from biogenic sulfuric acid attack.

- GRP is commonly selected in KSA/GCC for its low weight, corrosion resistance in sewer atmospheres, and good durability under high heat, UV, and wind-blown sand when properly formulated and detailed.pmc.

- Covers do not eliminate odors by themselves; they must be integrated with ductwork, fans, and an appropriately sized treatment unit (biofilter, carbon, or scrubber) whose design duty varies by process, airflow, and site conditions.

- Typical applications include headworks, primary clarifiers, selected aeration zones, sludge thickeners, and odorous sumps, each with different sealing levels, access needs, and span/deflection constraints.

- A robust STP tank cover design load specification should address dead load, live load (personnel and occasional equipment), wind, and thermal effects, plus allowable deflection and walkability expectations.

- Successful projects in KSA depend on buildable panelization, realistic access provisions, and installation methods suited to congested brownfield STPs or remote desert WWTP sites.

- Long-term O&M planning must cover safe access, fall protection, removable or hinged panels, replacement of seals, and inspection routines for structural elements and fixings.

- All detailed design choices (spans, loads, sealing, ventilation rates) should be confirmed with the project odor control designer and the client/AHJ, as requirements vary by process, airflow, and site conditions.

Odor and Corrosion Are Worse in STP/WWTP Environments

Open tanks and channels in STP and WWTP facilities create ideal conditions for generating H₂S and other nuisance gases, especially under high temperatures and long retention times. In KSA/GCC, elevated wastewater temperatures, industrial influent variability, and coastal salinity all accelerate biological activity and corrosion, while strong sun and dust storms stress exposed materials and equipment.justcapthat+10

Hydrogen sulfide generated in sewers and treatment structures can be biologically oxidized to sulfuric acid on moist concrete and metal surfaces, leading to biogenic sulfide corrosion and shortened asset life. Covers help by limiting direct oxygen ingress in some structures, stabilizing air paths for extraction, and reducing surface wetting by rain and condensate, which collectively can slow corrosion and improve odor capture when combined with proper ventilation.

What GRP Covers Do (And What They Don’t)

GRP covers for STP Saudi Arabia mainly provide containment of odorous air, physical shielding of walkways and mechanical equipment, and corrosion-resistant barriers above wastewater or sludge surfaces. They also reduce visual impact of open tanks near sensitive receptors and help keep sand, debris, and solar radiation off the water surface, which can marginally improve process stability in shallow structures.

However, GRP covers do not generate negative pressure, remove H₂S, or guarantee zero odor complaints on their own. Any claim of odor removal efficiency must come from the connected treatment system, not the cover, and will vary by process, airflow, and site conditions; designers should therefore treat covers as one part of a larger odor control system STP solution to be confirmed against the project specifications and AHJ requirements.nepis.epa+2

Typical STP/WWTP Applications for GRP Covers

For headworks channels, sealing levels are usually high because coarse screening, grit removal, and storm bypass lines are major odor sources. Access needs include frequent manual access for screenings handling and maintenance, so covers often combine fixed panels with hinged or removable sections over screens, with spans sized to balance stiffness, weight, and crane or manual handling limits.

Equalization basins often require medium to high sealing, depending on whether they buffer septic influent or industrial loads, and they may see significant water level variation. Access is generally less frequent but must allow for mixer maintenance and occasional desludging, so FRP covers wastewater tanks in this duty are usually laid out in modular bays with safe walk-on capability and removable pieces for equipment replacement where spans are constrained by available supporting beams.

Primary clarifiers are classic candidates for a primary clarifier GRP cover where odor and corrosion risk are high and surrounding land uses are sensitive. These tanks require controlled slots and penetrations for inlet/outlet launders, scum removal equipment, and bridges, with sealing strategies around moving mechanisms; spans are defined by tank diameter and bridge geometry, often using barrel shells or suspended flat elements to manage deflection and access.

Aeration tanks in KSA/GCC are typically only selectively covered, focusing on first bays or high-volatility industrial load zones, rather than fully enclosing all basins. Sealing is usually moderate (to enable ventilation while still allowing oxygen transfer effects to be considered), and access needs are high around diffusers, blowers, and mixers, so panels must be demountable and spans chosen to allow safe walkability without excessive weight.

Sludge thickeners, holding tanks, and gravity belt thickener feed wells can be strong localized odor sources and often receive corrosion resistant tank covers to limit H₂S exposure at ground level. Sealing is generally high with designated access hatches for sampling and equipment, and spans may be smaller but must account for point loads from maintenance personnel and occasional small equipment.

Chemical dosing chambers, odorous sumps, and buried valve chambers are normally compact but deep, with high localized H₂S and corrosive condensate. These are often fitted with robust, tight-sealing GRP access covers or small panel systems that emphasize gas-tightness around cable trays and piping penetrations, while still permitting safe entry and lifting in confined-space operations per local safety rules that reference international good practice on H₂S exposure limits.

Odor Control Basics: Cover + Ventilation + Treatment

Effective WWTP odor control covers follow a capture–convey–treat concept, in which GRP or FRP covers wastewater tanks to capture odorous air, fans convey it through ductwork, and a downstream unit treats the pollutants. Commonly used treatment systems include biofilters, activated carbon units, and chemical scrubbers, all of which must be sized and configured for the specific influent characteristics and design airflows, which vary by process, airflow, and site conditions.

A simple “system block diagram” for an odor control system STP typically starts with covered tanks and channels, followed by local duct pickups, manifold headers, extraction fans, and then one or more odor control units exhausting via a stack to a safe height. Designers should coordinate cover detailing (penetrations, flanges, supports) early so that leakage is minimized, pressure drops are reasonable, and airflows are consistent with project odor control designer calculations and AHJ requirements, given that recommended ventilation rates are provided in standards and utility guidelines and vary by process, airflow, and site conditions.

Corrosion Protection: Why GRP Works in Sewer Atmospheres

In sewer and STP atmospheres, H₂S oxidizes to sulfuric acid on moist surfaces, which aggressively attacks concrete, steel, and cast iron, reducing structural capacity and shortening service life. GRP laminates are inherently corrosion resistant against many wastewater-related acids and salts, and field experience and testing show that well-designed GRP components can maintain performance in harsh sewer environments for extended periods when compared to unprotected metallic or concrete elements.

Because GRP does not rely on sacrificial mechanisms and can be tailored with resins and veils suited to the expected chemical exposure, it is commonly used for corrosion resistant tank covers and ducting above aggressive wastewater. Nevertheless, designers in KSA/GCC should verify resin selection, laminate build-up, UV protection, and grounding provisions (where electrostatic considerations apply) with the supplier and ensure alignment with any project standards or client specifications, as acceptable solutions vary by process, airflow, and site conditions.

Cover Design Considerations (Loads, Spans, Deflection)

Designing GRP covers for STP Saudi Arabia starts with defining the STP tank cover design load envelope, including self-weight, live loads for personnel, occasional maintenance equipment, wind uplift, and thermal effects specific to KSA/GCC climates. Spans must then be chosen so that deflections under these loads remain within acceptable limits for walkability, seal performance, and drainage, while still allowing economical panel sizes and transport.

Support arrangements may include self-supporting barrel shells, flat panels on concrete beams, or GRP panels suspended from steel lattice structures, each with different stiffness and installation implications. A commonly used approach is to base allowable deflection criteria and walk-on ratings on project-specific structural analysis and to coordinate clearly with the structural engineer of record and the project odor control designer, because acceptable limits vary by process, airflow, and site conditions and because local AHJ or utility standards may influence the required safety factors.

Installation Best Practices (KSA) — step-by-step list

- Confirm final tank dimensions, openings, and interference points on site, accounting for construction tolerances and any retrofits typical of brownfield STPs.

- Verify that supporting concrete or steel structures are finished, level, and ready to accept anchor systems, with any corrosion protection or waterproofing membranes completed.

- Preassemble large GRP elements or barrel shells on the ground where space allows, following project-specific lifting and bracing instructions suited to local crane availability and site logistics.

- Use mobile or gantry cranes sized for reach and weight in high-temperature, dusty conditions, and plan lifts to avoid overhead power lines, existing process equipment, and operational areas.

- Install primary support elements (e.g., main beams, barrel shells, or steel trusses) first, align them carefully, and secure them to supports before placing secondary GRP cover panels.

- Install seals, gaskets, and edge details progressively, paying attention to transitions at walls, bridges, and pipes so that odor containment and rainwater management objectives are met.

- Fit access hatches, ladders, handrails, and fall protection hardware in accordance with the project safety plan and applicable safety guidance on working near H₂S and confined spaces.pmc.ncbi.nlm.nih+2

- Check panel joints, fasteners, and seals for continuity, verify that doors and hatches operate smoothly, and commission any integrated duct connections or penetrations before final acceptance.

- Provide the operator with as-built drawings, an installation report, and a concise inspection and maintenance checklist tailored to KSA/GCC operating conditions.

O&M: Access, Safety, and Maintenance Planning

Operation and maintenance planning for GRP covers in KSA/GCC should start at design stage by defining which panels are walkable, which are removable, and where safe access points and fall protection systems are needed. Because many covered areas may be classified as confined spaces with potential for elevated H₂S, operators must align procedures with recognized exposure limits and safe entry practices, as documented in occupational safety literature, while confirming requirements with their own HSE and AHJ frameworks.

Routine inspections should focus on seals, fixings, visible laminate surfaces, and any steel support structures, checking for UV degradation, mechanical damage, or corrosion, especially in coastal and industrial locations. A commonly used approach is to implement a periodic cleaning regime to remove dust and sand, combined with planned replacement of gaskets and re-coating of any exposed metallic parts, with details and intervals confirmed with the project odor control designer, GRP supplier, and client specifications.

Common Mistakes to Avoid

- Treating GRP covers as purely architectural items and omitting early coordination with the odor control designer and process engineer.

- Assuming covers alone will solve odor complaints without verifying ventilation strategy, treatment capacity, and stack discharge conditions with the project team.unitywater+2

- Underestimating STP tank cover design load requirements, leading to excessive deflection, ponding, or unsafe walkability for operators.

- Ignoring KSA/GCC-specific climate factors such as high solar gain, thermal expansion, and abrasive dust/sand when detailing joints and fixings.

- Providing inadequate access openings or overcrowding covers with small hatches that make routine maintenance and equipment removal difficult.

- Neglecting sealing details around moving bridges, scum pipes, cables, and ducts, which can become major odor leakage paths.

- Failing to coordinate duct connection points and support loads with both the cover supplier and the structural engineer, resulting in ad hoc field modifications.

- Overcomplicating panel layouts so that removal requires large cranes or temporary dismantling of handrails and pipework on every intervention.

- Omitting clear marking of walkable versus non-walkable areas, increasing the risk of unsafe loading or falls.

- Ignoring grounding and electrostatic considerations where required in explosive or high-H₂S environments, instead of confirming needs with the project’s electrical and safety engineers.

- Skipping or delaying inspection of steel substructures or anchors, which can corrode in aggressive sewer or coastal atmospheres even when GRP elements remain intact.

- Not documenting installation assumptions, access strategies, and maintenance requirements for handover to future operators and maintenance contractors.

FAQs

Q1: Do GRP covers for STP Saudi Arabia eliminate odors completely?

A: No. GRP covers help capture odorous air but do not remove H₂S or other gases by themselves; effective odor reduction depends on properly designed extraction and treatment systems whose performance varies by process, airflow, and site conditions and must be confirmed against project specifications and AHJ requirements.

Q2: How do GRP covers contribute to H2S corrosion protection?

A: By limiting the exposure of concrete and steel surfaces to H₂S-laden air and condensate, GRP covers and associated corrosion resistant tank covers can slow biogenic sulfuric acid attack, especially when combined with appropriate ventilation and lining systems, though detailed protection strategies must be confirmed with the project odor control designer and client standards.

Q3: Where are WWTP odor control covers most critical in KSA/GCC plants?

A: They are commonly prioritized at headworks, primary clarifiers, sludge handling areas, and particularly odorous sumps near sensitive boundaries, but exact priorities vary by process layout, industrial contributions, and local planning conditions, and should be confirmed with the project odor control designer and AHJ.

Q4: What makes GRP suitable for FRP covers wastewater tanks in harsh Gulf climates?

A: GRP offers good corrosion resistance, low weight, and suitability for hot, UV-intensive, and dusty environments when the resin, laminate, and UV protection are correctly specified; however, designers should validate the proposed system with the supplier for the specific KSA/GCC site conditions.

Q5: How are design loads and deflections for primary clarifier GRP cover systems defined?

A: Loads and allowable deflections are typically established through structural analysis based on project-specific requirements for live loads, wind, and thermal effects, and should be documented in the STP tank cover design load specification and coordinated with the structural engineer and client standards, as acceptable criteria vary by process, airflow, and site conditions.

Q6: What ventilation rates should be used for enclosed tanks and channels?

A: Utilities and engineering guidelines provide methods and minimum airflow recommendations for different assets, but actual ventilation rates for any odor control system STP must be calculated by the project odor control designer and confirmed in the specifications, since suitable values vary by process, airflow, and site conditions and should reference recognized guidance where applicable.

Q7: How often should GRP covers be inspected and maintained in KSA/GCC?

A: A commonly used approach is to carry out visual inspections at least annually, with more frequent checks in highly corrosive or coastal locations, and to follow a maintenance plan covering seals, fasteners, cleaning, and any associated steelwork, with intervals refined by the operator, designer, and client specifications.

Q8: Can GRP covers be retrofitted to existing STP tanks without major civil works?

A: Yes, many GRP cover systems are designed for retrofit, using modular panels and support arrangements that adapt to existing tank geometries, but feasibility depends on available edge support, access for lifting equipment, and integration with the planned odor control system, all of which must be reviewed by the project team for the specific KSA/GCC site.

Conclusion

In KSA/GCC conditions, GRP covers perform best when the design confirms loads, sealing, ventilation interfaces, and maintenance access.

Ready to proceed? Send your drawings and requirements and we’ll respond with a project-specific GRP cover concept and quotation.

👉 Request a Quote

- Tables (all tables together)

Odor and corrosion by plant area

| Plant area | Typical odor sources | Corrosion risk | Why covers help |

|---|---|---|---|

| Headworks (screens, grit) | Septic influent, screenings, grit and grease handling, turbulence at drops. | High H₂S and moisture leading to biogenic sulfide corrosion on concrete and steel. | Enable focused extraction of foul air, protect structures and equipment from spray, and reduce ground-level odor near plant boundaries. |

| Equalization basins | Long retention, stratification, industrial load swings, surfacing gases. | Prolonged exposure to H₂S and acidic condensate on walls and decks. | Stabilize air capture, limit rain and dust ingress, and allow controlled ventilation to treatment units. |

| Primary clarifiers | Rising sludge, scum, septic solids and liquids, inlet turbulence. | Severe biogenic sulfuric acid attack at air–water interface and in headspace. | Improve odor capture, shield concrete rims and steel bridges, and support integrated air extraction. |

| Aeration basins (selected) | First bays with high organic load, industrial shocks, foam breakdown. | Moderate to high, especially in upstream or selector zones. | Allow selective capture of high-odor zones without enclosing entire basin surface, enabling targeted treatment. |

| Sludge thickeners/handling | Concentrated sludge storage, mixing, pumping, truck loading. | High H₂S and corrosive condensate attack on structures and equipment. | Reduce worker exposure, protect structural elements, and allow direct duct connection to odor units. |

| Chemical dosing/sumps | Acid/alkali dosing fumes, turbulent mixing of wastewater and chemicals. | Localized aggressive atmospheres that challenge many materials. | Provide compact, tight covers for small but critical sources, with penetrations sealed around cables and pipes. |

Cover design elements and common issues

| Design element | Why it matters | What to specify | Common mistake |

|---|---|---|---|

| Global STP tank cover design load | Ensures covers can safely support self-weight, personnel, and occasional equipment under KSA/GCC climate conditions. | Define dead and live loads, wind uplift, thermal effects, walkability expectations, and relevant safety factors in the project specification (varies by process, airflow, and site conditions). | Using generic building-code loads without checking against actual maintenance practices and local utility or AHJ requirements. |

| Span and deflection limits | Excessive deflection can damage seals, cause ponding, or create unsafe walking surfaces. | Set maximum permissible deflections for main and secondary elements and align with panel geometry, support spacing, and drainage strategy. | Ignoring deflection checks for long spans or accepting very flexible layouts that compromise sealing and drainage. |

| Sealing and edge details | Air leakage reduces odor capture efficiency and can shift odor issues to unexpected locations. | Specify gasket types, compression requirements, edge upstands, and treatments at walls, bridges, and penetrations, coordinated with ventilation design. | Leaving sealing details to site improvisation, resulting in gaps around pipes, bridges, and joints. |

| Access strategy | Adequate access is critical for safe O&M, equipment replacement, and emergency interventions. | Define which panels are fixed, hinged, or removable, mark walkable areas, and coordinate hatch size and location with mechanical and safety requirements. | Over-reliance on many small hatches or very large monolithic panels that are impractical to remove in constrained STP layouts. |

| Corrosion and UV protection | Gulf environments impose strong UV, heat, moisture, and salt loads that can affect GRP and associated hardware. | Specify suitable resin systems, UV protection, compatible fixings, and any required coatings, plus inspection intervals for metallic supports. | Assuming standard GRP and hardware will perform indefinitely without considering KSA/GCC-specific exposure conditions. |

| Integration with odor system | Covers must work with fans, ducts, and treatment units to achieve odor control objectives. | Define interface details for duct connections, support loads, and target leakage limits, coordinated with the odor control designer (varies by process, airflow, and site conditions). | Designing covers and odor systems separately, leading to rework and suboptimal performance. |