Introduction

FRP water tank size Saudi Arabia is not a guessing game—this guide shows a practical method to calculate the right capacity for villas and factories. Undersizing leads to frequent outages, pump cavitation, and costly emergency water deliveries. Oversizing wastes capital, consumes valuable rooftop/courtyard space, and—critically—creates stagnation risk in the Kingdom’s extreme heat, compromising water hygiene. The difference between a 5 m³ tank and a 10 m³ tank can mean SR 8,000–15,000 in additional investment plus ongoing space/maintenance burden.

Use this method to select the correct FRP water tank size Saudi Arabia for villas, factories, and mixed-use facilities. You will learn how daily consumption, storage autonomy, climate conditions, and installation constraints shape the final tank configuration. All recommendations reference Saudi Building Code (SBC), SASO-GSO-1831 standards, and real consumption data from the Kingdom’s water authority. By the end, you’ll have a calculation framework to present to your supplier or engineer with confidence.

Quick Answer: Tank Sizing in Saudi Arabia

- Villa baseline: Multiply occupancy (people) × 100–150 liters/person/day × 2 storage days = minimum capacity. Add 20–30% buffer for guests, maids, and garden water in KSA.

- Factory approach: Separate calculation for domestic staff + process water (industry-specific) + washdown + contingency buffer. Fire water often requires a dedicated tank per authority spec.

- Storage autonomy concept: 1–2 days for reliable municipal supply; 3–5 days if supply is intermittent (common in some Saudi regions); 5–7 days for remote sites or production continuity. Varies by city and location.

- Space/installation limits are real: Rooftop load capacity, ground footprint, access for cleaning and manhole removal all constrain tank size. Confirm with structural engineer and local authority before finalizing.

- Hygiene and turnover matter: Oversizing creates stagnation risk in heat; aim for 70–80% daily water turnover (tank drains/refills most of its volume daily). Undersize and you lose redundancy.

- Coastal and remote sites: If near salt spray (Jeddah, Dammam, Eastern Province), FRP’s non-corrosive advantage justifies capacity planning. Remote areas demand higher buffer days due to delivery uncertainty.

- Multi-tank strategy beats single large tank: Two 10 m³ tanks instead of one 20 m³ tank provides maintenance access without supply loss and improves water turnover. Key advantage in KSA’s quarterly-to-monthly cleaning schedules.

- Before requesting a quote: Gather occupancy count, estimated daily usage, storage days needed, available space (height + footprint), location (coastal/remote), and installation location (rooftop/ground). These inputs finalize size.

FRP Water Tank Size Saudi Arabia: Quick Calculation Method

Occupancy and Usage Pattern

The primary driver of tank size is occupancy: how many people use the water, for how long, and with what daily consumption pattern. A villa housing a nuclear family of 4 has different needs than the same villa during Ramadan or Hajj season when it houses extended family, guests, and household staff.

Current Saudi per capita water consumption averages 102 liters/day (2023 baseline). However, this includes municipal average. Individual villas often consume 100–150 liters/person/day when accounting for domestic use (toilets, showers, laundry, cleaning). Add garden/courtyard watering in the hot season, and consumption per capita can spike to 200+ liters/day in large villas with landscaping.

Daily Demand Variability

Water use is not uniform. Peak demand occurs during morning (showers) and evening (cooking, cleaning). Factories face different patterns: high demand during production runs, minimal demand during maintenance shutdowns. A textile factory may require 100–150 liters of water per kilogram of fabric (mostly cooling and processing), while food facilities use 3–10 liters/kg of product.

Intermittent Supply Risk and Buffer Days

Saudi Arabia’s water supply varies by region. Riyadh and major cities have reliable municipal supply; some suburban and rural areas experience intermittent supply or pressure loss during peak hours. The National Water Company (NWC) guidelines recommend that residential tanks be sized to provide autonomy of at least 6 months of cleaning intervals, but practically, 2–5 storage days balances cost and reliability.

Peak Demand vs Average

Villas do not consume water at a constant rate. Peak demand occurs when multiple showers, laundry, and outdoor watering happen simultaneously. Tank sizing must account for peak flow, not just daily average. A rule of thumb: peak instantaneous demand can be 2–3× average hourly rate.

Industrial Process Water

Factories require separate accounting for:

- Domestic water: Staff toilets, showers, canteen (similar to villa calculation per employee)

- Process water: Specific to industry (cooling, washing, chemical dilution, boiler feed)

- Washdown and cleaning: General facility sanitation

- Contingency: Delivery delays, production upsets, peak season demand

Each component is estimated independently, then summed. Process water dominates factory tank size and is highly industry-specific.

Temperature and UV: Operational Implications

Saudi Arabia’s heat (45–50°C+ in summer) affects tank strategy. High water temperature (45°C+) encourages bacterial and algal growth; stored water must turn over frequently to remain hygienic. Oversized tanks in direct sun risk stagnation and biofilm despite chlorination. FRP’s non-corroding properties in heat allow extended lifespan, but smart sizing (avoiding stagnation) is still essential.

Step-by-Step Tank Sizing Method (Simple Formula)

Step 1: Define Use Type

Are you sizing for:

- Residential villa (domestic use only, includes outdoor watering)

- Factory/industrial (domestic + process + washdown)

- Mixed-use facility (e.g., estate with worker housing + processing)

- Remote/agricultural site (isolated supply, high delivery uncertainty)

Each has different calculation inputs and buffer assumptions.

Step 2: Estimate Daily Demand (m³/day)

For residential:

- Occupancy (number of people) = N

- Daily consumption per person = 100–150 L/day typical (varies with villa size, garden, climate awareness)

- Daily demand = N × 100–150 liters = ? m³/day

Example: Family of 4 + 2 household staff + frequent guests = 6 occupants × 125 L/day = 750 L/day = 0.75 m³/day

For industrial:

- Domestic staff water = (# employees) × 40–50 L/day (toilets, washing)

- Process water = per unit product or batch (from process engineering or supplier data)

- Washdown/cleaning = area-based estimate or historical data

- Daily demand = Sum of above = ? m³/day

Example: Food processing facility: 50 staff × 50 L + 10 m³ process water (production schedule) = 2.5 m³ + 10 m³ = 12.5 m³/day

Step 3: Choose Storage Autonomy (Days)

How many days of water supply should the tank provide without external supply?

- 1–2 days: Reliable municipal supply, minimal interruption risk, short delivery time from tankers if needed

- 3–5 days: Intermittent supply common in area, or production continuity required (acceptable downtime = 0 days)

- 5–7 days: Remote location, delivery unreliable, or critical industrial process

Example: Villa in Riyadh (reliable supply) = 2 days autonomy. Remote agricultural site = 5 days autonomy.

Step 4: Add Contingency Percentage

Account for unexpected demand: guest surges, delivery delays, pump failures, water loss to maintenance/cleaning.

Contingency buffer = 20–30% of base capacity (accounts for these variables without massive oversizing)

Step 5: Check Turnover (Daily Draw Minimum)

Ensure tank capacity is not so large that water stagnates.

Minimum daily water draw should be ≥70–80% of tank capacity per day to avoid stagnation in heat.

Example: 10 m³ tank should draw 7–8 m³/day minimum. If daily demand is only 0.5 m³/day, the tank is oversized. Either reduce tank size or ensure supplementary use (garden watering, process water) fills the gap.

Step 6: Check Installation Constraints

Does the tank fit physically?

- Rooftop: Verify structural load capacity (typically 5–10 kN/m² for villas; large tanks exceed this)

- Ground/courtyard: Available footprint? Access for maintenance truck? Drainage slope?

- Manhole and vent accessibility: Can a person enter for cleaning every 6 months? Can vent screen be reached?

- Inlet/outlet size: Confirm pump connections match available sizes (typically 1–2 inch for residential)

If constraints prevent the calculated size, reconsider placement (move from roof to ground) or multi-tank approach (two smaller tanks instead of one large).

Step 7: Select Tank Configuration

Choose between:

- Single large tank: Simplest installation, lowest footprint per cubic meter, but no maintenance redundancy

- Multiple smaller tanks: (e.g., 2×10 m³ instead of 1×20 m³) Allows one tank offline for cleaning while the other supplies; better turnover in KSA climate

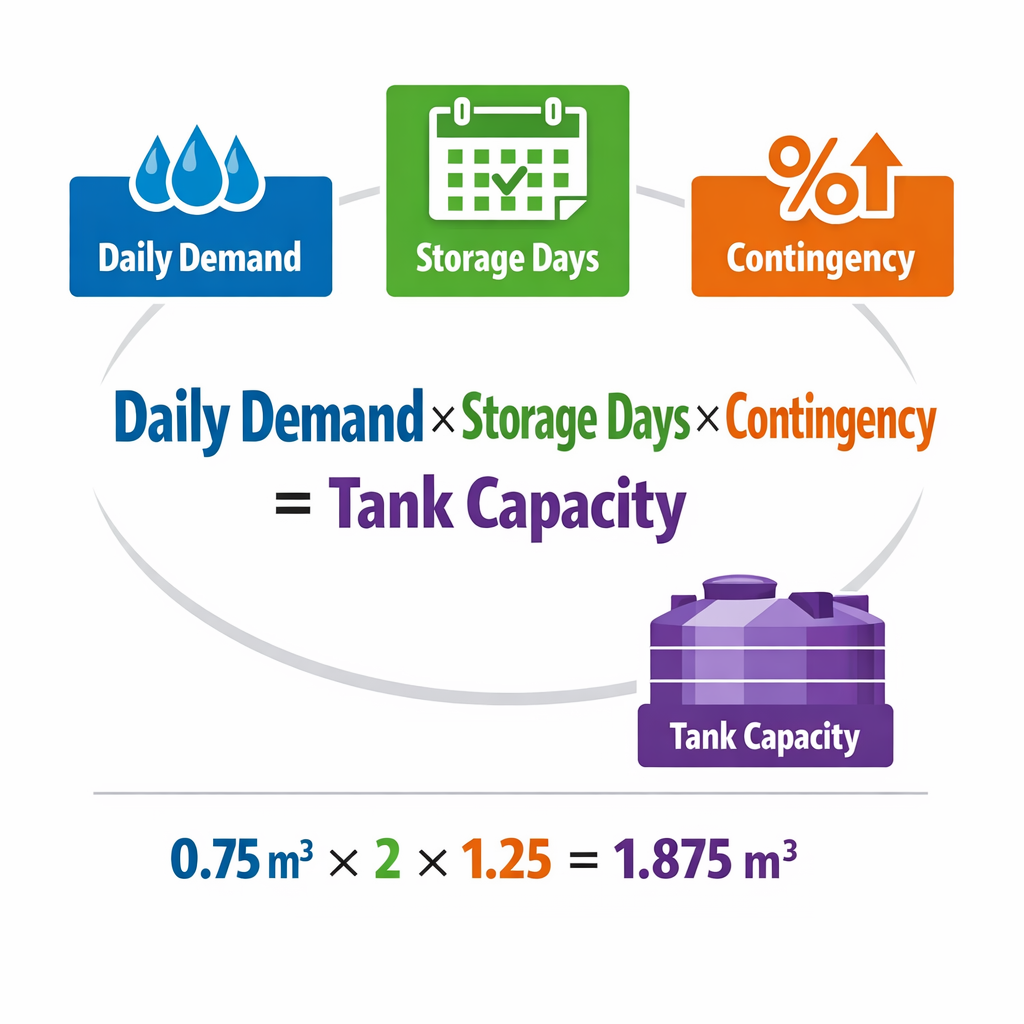

SIZING FORMULA (Text Representation)

textTank Capacity (m³) = [Daily Demand (m³/day) × Storage Days] × (1 + Contingency %)

Adjusted for turnover: Verify that Daily Demand ≥ 70% × Tank Capacity

Example:

Daily Demand = 0.75 m³/day (villa)

Storage Days = 2

Contingency = 25%

Tank Capacity = (0.75 × 2) × 1.25 = 1.5 × 1.25 = 1.875 m³

→ Round up to 2.0 m³ or 2×1 m³ modular tanks

Villa / Residential Sizing (KSA)

Residential Consumption Framework

Domestic water use in Saudi Arabia averages 102 liters/person/day (national 2023 figure), though this includes industrial/agricultural sectors. For a single villa, assume 100–150 liters/person/day as a practical range, depending on occupancy density and garden size. Large villas with gardens and outdoor courtyards may approach 150+ liters/person/day in the summer watering season.

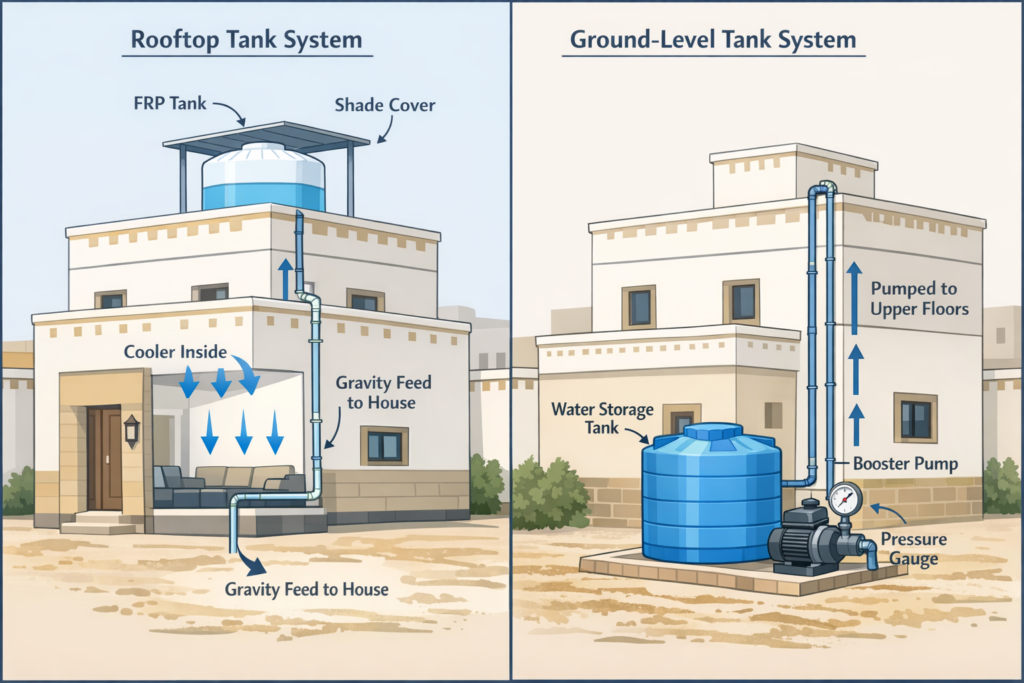

Rooftop vs Ground Placement Trade-offs

| Placement | Pros | Cons | KSA Note |

|---|---|---|---|

| Rooftop | Gravity-fed distribution; low pump cost; space-efficient | Structural load limits tank size; heat accelerates biofilm; maintenance access difficult | Verify roof beam capacity; shade structure recommended to reduce water temperature |

| Ground/Courtyard | Larger capacity possible; easier access for cleaning; lower structural cost | Requires booster pump for upper floors; larger footprint; heat exposure if unshaded | Common in villas; allow space for foundation, drainage |

| Underground | No surface footprint; cooler water (reduces biofilm); aesthetic | High excavation cost; pump required; difficult access for cleaning/manhole removal | Less common in residential KSA due to soil conditions and flooding risk |

Multi-Tank Recommendation

For villas requiring >5 m³ capacity, split into 2 or 3 smaller tanks (e.g., 2×5 m³ instead of 1×10 m³). Benefits:

- One tank can be offline for mandatory 6-month cleaning without loss of supply

- Better water turnover in hot climate (each tank circulates more frequently)

- Load distribution on roof or courtyard base

- Simplified installation and maintenance access

Villa Sizing Table

| Villa Scenario | Occupancy Assumption | Daily Use Drivers | Suggested Capacity (m³) | Storage Days | Notes |

|---|---|---|---|---|---|

| Small villa, 3 occupants, no garden | 3 persons | Toilets, showers, laundry, kitchen, cleaning | 0.5–1.0 | 2 | ~90–100 L/person/day. Adequate for compact villa. |

| Medium family villa, 4–5 occupants, small garden | 5 persons (family + maid) | Toilets, showers, laundry, kitchen, modest watering | 1.0–2.0 | 2 | ~100–120 L/person/day. Typical Riyadh villa. |

| Large villa, 6+ occupants, large courtyard/garden | 6–8 persons (extended family, 1–2 staff) | High toilet/shower frequency, laundry, outdoor watering (seasonal) | 2.5–5.0 | 2–3 | ~120–150 L/person/day including garden. Summer peak can exceed 200 L/person/day if garden is lush. |

| Coastal villa (Jeddah/Dammam), 5 occupants, garden | 5 persons | Same as above + salt spray impacts (cover/maintenance) | 1.5–2.5 | 2–3 | FRP advantage evident here. Intermittent supply common in coastal areas; consider 3-day buffer. |

| Ramadan/holiday occupancy variation | 3 persons (base) → 8+ (guests) | Multiply by 2–3× normal demand during guest season | Base + 30% buffer | 2 | Plan base capacity for normal occupancy; buffer handles surge. Alternative: temporary tanker supply during peak season. |

Factory / Industrial Sizing (KSA)

Separating the Water Uses

Industrial water demand is not uniform. Break it into components:

- Domestic amenities water (staff facilities)

- Process water (specific to manufacturing)

- Cleaning/washdown water (facility maintenance)

- Contingency (delivery delays, production upsets)

- Fire water (often separate tank per spec—see note below)

Fire Water: Separate Calculation

Fire water tanks are typically specified separately by the fire authority or client, based on building hazard classification and occupancy. Saudi Civil Defense regulations often require fire tank capacity of 40 m³+ for large facilities. This is not combined with potable/process storage in standard design. Consult with your fire safety engineer or local authority for fire tank specifications; it is outside the scope of this article.

Industrial Estimation Method

| Factory Type (Generic Example) | Water Drivers | How to Estimate | Common Mistakes | Notes |

|---|---|---|---|---|

| Small food processing (20–50 staff) | Domestic (staff): 50 L/person/day; Process (washing, cleaning, boiler): 2–5 m³/day; Washdown: 1 m³/day | Staff count × 50 + (production schedule/history) + facility area; Contact machinery suppliers for cooling/process specs | Forgetting boiler feed water; underestimating washdown frequency | Typical total: 5–15 m³/day. Intermittent production requires buffer days (2–3 days storage recommended). |

| Textile/garment factory (100–200 staff) | Domestic: 50 L/person/day; Wet processing (dyeing, washing): 100–150 L/kg fabric produced; Cooling: 5–20 m³/day depending on dye machines | Staff + daily fabric throughput (kg) × process rate; Request spec sheet from dye machine supplier for cooling water | Overestimating process water without production schedule; ignoring seasonal demand changes | Typical total: 20–50 m³/day. High variability with production run intensity. Recommend 3–5 day buffer for supply interruptions. |

| Pharmaceutical/chemical (small batch, 50 staff) | Domestic: 50 L/person; Process: 10–30 m³/day (cooling, reactions, cleaning equipment); Washdown: 2–3 m³/day | Consult process engineer for batch specs; cooling water often recycled (RO or cooling tower) so fresh supply lower than raw process water | Confusing process water circulation (recycled) with fresh water demand; ignoring chemical compatibility | Typical fresh water demand: 10–20 m³/day. Multi-day buffer critical (supply loss halts production). Recommend 5–7 day storage. |

| Logistics/warehouse (100–150 staff, minimal process) | Domestic: 50 L/person/day; Cleaning (floors, vehicles): 3–8 m³/day; Landscaping/dust control: 2–5 m³/day | Staff + facility area (estimate 50–100 L/m²/day for cleaning) | Underestimating cleaning water (especially in dusty KSA); forgetting landscape watering | Typical total: 10–20 m³/day. Reliable local supply common for industrial areas; 2–3 day buffer often adequate. |

| Manufacturing plant (automotive, assembly, 300+ staff) | Domestic: 50 L/person; Cooling systems: 50–100 m³/day (if water-cooled machinery); Washdown: 5–10 m³/day; Cleaning: 2–5 m³/day | Contact each equipment supplier for cooling water spec; cooling is usually largest demand. May use recycled water for non-critical cooling. | Overestimating fresh water if plant uses cooling tower recirculation; ignoring potential for water reuse | Typical fresh water: 30–80 m³/day (cooling often 50–80% of total). Large plants often implement water recycling. 3–5 day buffer recommended. |

Head-to-Head: Oversizing vs Undersizing

The choice of tank size involves real trade-offs. Neither oversizing nor undersizing is “safe”—both carry operational and financial costs.

| Oversizing Risks | Undersizing Risks |

|---|---|

| Stagnation: In Saudi heat (45°C+), water >10 days old without circulation develops biofilm and foul smell; mandatory quarterly cleaning adds cost. | Service Interruption: Villa loses water mid-day; factory halts production; emergency tanker delivery (SR 200–400/trip) becomes necessary. |

| Higher capex: Tank cost scales with volume; 20 m³ costs ~40% more than 15 m³. | Pump stress: Low pressure/cavitation damages pump; reduces lifespan; higher maintenance cost. |

| Footprint burden: Rooftop tanks limit solar panels or other roof use; ground tanks consume courtyard space. | Supply risk: If delivery is delayed 1 day, undersized tank fails to buffer. No redundancy for maintenance. |

| Turnover issue: If daily demand is 1 m³ but tank is 10 m³, turnover is only 10%/day → stagnation. Must increase demand (garden watering) or reduce tank. | Multiple tanks required anyway: If you need 5 m³ buffer but choose 3 m³ tank, you still buy tankers monthly → may as well size to 5 m³ from start. |

| Long-term hygiene: Stagnation increases chemical treatment needs and water quality degradation. | Operational burden: Staff worry about running out; morale and safety affected. |

Installation Constraints That Change the Answer

Real-world constraints often force practical compromises. Engineering design must account for these:

Rooftop Structural Load

Residential villas typically have rooftop beam capacity of 5–10 kN/m² (varies by villa age and design). A 10 m³ FRP tank weighs ~12,000 kg (12 metric tonnes), exerting ~12 kN of load. Confirm with a structural engineer before placing large tanks on roofs. If roof cannot support it, move tank to ground or split into 2×5 m³ on separate beams.

Base Preparation and Flatness

FRP tanks must sit on flat, level surfaces (concrete pad minimum 150 mm thick, reinforced). Uneven settling causes localized stress at tank shell and bolt flanges, leading to slow leaks. Poor base is a #1 cause of tank failure, not material defect. Verify site preparation before delivery.

Access for Maintenance

Manhole diameter (typically 600–800 mm) must be accessible for entry during mandatory 6-month cleanings in KSA. Rooftop tanks may be difficult to service (narrow roof, no crane access). Verify access path before committing to location.

UV and Shade Considerations

Unshaded FRP tanks in direct sun experience higher internal water temperatures (45–50°C+). While FRP gelcoat resists UV, high water temperature accelerates biofilm growth, requiring more frequent cleaning. Install shade structures (simple frame with cloth or mesh) to reduce water temperature by 5–10°C and extend tank service life.

Multi-Tank Manifold Design

If multiple tanks are required (e.g., 2×10 m³), they must be connected via manifold (common inlet/outlet header) for automatic load balancing and cross-circulation during standby. FRP modular design simplifies this: bolted connections allow on-site integration. Steel or concrete tanks require complex welding/construction.

FRP Modular Advantage

FRP tanks arrive as bolted sections, assembled on-site. This enables:

- Flexible placement: Multiple smaller tanks can fit rooftops that reject one large tank

- Phased capacity expansion: Add tanks later if demand increases

- Simplified maintenance: Each tank cleanable independently without full supply loss

Worked Examples (3 Scenarios)

Example 1: Medium Villa in Riyadh (Reliable Supply, Occupancy-Based)

Assumptions:

- Location: Riyadh (reliable municipal supply)

- Occupancy: 5 people (family of 4 + 1 maid)

- Daily consumption: 120 L/person/day (average for villa with modest watering)

- Storage autonomy: 2 days (adequate buffer for reliable supply)

- Contingency: 25% (account for guest surges, dry season garden watering)

Calculation:

textDaily Demand = 5 people × 120 L/person/day = 600 L/day = 0.6 m³/day

Base Capacity = Daily Demand × Storage Days

= 0.6 m³/day × 2 days = 1.2 m³

With Contingency (25%) = 1.2 m³ × 1.25 = 1.5 m³

Turnover Check: Daily Demand (0.6 m³) ÷ Tank Capacity (1.5 m³) = 40% turnover/day

This is acceptable for residential use (no stagnation risk at 40%+ turnover)

Recommended Configuration:

- 2 × 0.75 m³ tanks (total 1.5 m³), OR

- 1 × 1.5–2.0 m³ tank (single unit)

Rationale: Two smaller tanks allow one offline for quarterly cleaning without supply loss. Installation location: rooftop (typical for villas) or ground if rooftop cannot support load.

Example 2: Small Food Processing Factory in Jeddah (Process + Contingency)

Assumptions:

- Location: Jeddah (coastal, intermittent supply during peak hours, 2–3 year old facility)

- Occupancy: 40 staff + production

- Daily staff water: 40 people × 50 L/day = 2 m³/day

- Process water (cleaning, cooling, batch filling): 8 m³/day (estimated from machinery specs)

- Washdown/facility cleaning: 2 m³/day

- Storage autonomy: 3 days (coastal area, intermittent supply common; production continuity important)

- Contingency: 30% (account for delivery delay if supply interrupts)

Calculation:

textDaily Demand = 2 + 8 + 2 = 12 m³/day

Base Capacity = Daily Demand × Storage Days

= 12 m³/day × 3 days = 36 m³

With Contingency (30%) = 36 m³ × 1.30 = 46.8 m³ ≈ 47 m³

Turnover Check: Daily Demand (12 m³) ÷ Tank Capacity (47 m³) = 25.5% turnover/day

This is on the low side but acceptable for industrial (process water is often recycled/cooled, so "fresh" turnover is adequate)

Recommended Configuration:

- 4 × 12 m³ tanks (total 48 m³) in parallel manifold, OR

- 2 × 24 m³ tanks (if space allows)

Rationale: Multiple tanks provide:

- Load distribution on facility yard/foundation

- Redundancy for maintenance (clean one tank while others serve production)

- Modular growth (can add tank later if production increases)

- Better compliance with KSA quarterly cleaning schedules (one tank offline at a time, minimal disruption)

Example 3: Remote Agricultural Site (High Delivery Risk, Buffer Days Critical)

Assumptions:

- Location: 200 km south of Riyadh, agricultural cooperative, nearest water tanker delivery = 3–4 hours

- Occupancy: 50 workers (housing + packing shed)

- Daily staff/domestic water: 50 × 80 L/day = 4 m³/day (lower per capita in remote area, basic facilities)

- Irrigation/farm operations: 15 m³/day (seasonal; average year-round ~8 m³/day)

- Storage autonomy: 5 days (delivery uncertain; supply loss = major operational loss)

- Contingency: 40% (account for vehicle breakdown, seasonal demand spikes)

Calculation:

textDaily Demand = 4 + 8 (average farm ops) = 12 m³/day

Base Capacity = Daily Demand × Storage Days

= 12 m³/day × 5 days = 60 m³

With Contingency (40%) = 60 m³ × 1.40 = 84 m³

Turnover Check: Daily Demand (12 m³) ÷ Tank Capacity (84 m³) = 14.3% turnover/day

Low turnover, but acceptable for remote agricultural site where stagnation risk is lower (cooler night temps, periodic irrigation drawdown)

Recommended Configuration:

- 3 × 28 m³ tanks (total 84 m³) in parallel manifold, OR

- 6 × 14 m³ tanks if area permits (maximum flexibility, allows rotation for maintenance)

Rationale: Remote sites demand multiple safety margins:

- High autonomy (5 days) buffers irregular delivery

- Multiple tanks eliminate total supply loss during cleaning

- Modular FRP design is cost-effective for large capacity

- Seasonal demand (irrigation spike in summer) managed by base sizing at average, with full contingency buffer

Sizing Checklist Before You Request a Quote

Copy and send this to your tank supplier or engineer:

- Location: City/region (e.g., Riyadh, Jeddah, Eastern Province, remote area)

- Application type: Residential villa / Industrial factory / Mixed-use / Agricultural

- Occupancy/staff count: How many people use the facility daily?

- Estimated daily consumption: m³/day (use formulas above, or provide historical bills if available)

- Preferred storage days: 2 days / 3 days / 5 days / 7 days? (Select based on supply reliability)

- Available space: Rooftop (dimensions, weight limit) / Ground/courtyard (footprint, height limit)

- Installation location: Rooftop / Ground / Underground

- Water inlet/outlet size preference: 1 inch / 1.5 inch / 2 inch? (Confirm pump/plumbing connection size)

- Access requirement: Manhole size, cleaning schedule frequency

- Delivery/installation constraints: Can crane reach installation site? Road access? Timeline?

- Standard compliance: SASO-GSO-1831 (potable water), NSF 61 certification required?

- Budget and contingency: Rough budget range (helps supplier recommend modular vs single-tank solution)

Common Mistakes to Avoid

- Guessing capacity with no daily demand estimate. Use the formula: occupancy × daily rate × storage days. Do not rely on “that villa used 10 m³” unless it has identical occupancy and weather.

- Ignoring intermittent supply and buffer days. A villa in an area with 2–3 hour daily water cuts needs 3+ days of storage, not 1 day. Check with local water authority.

- Combining fire water and potable storage without specification. Fire tanks have different design, pressure, and usage rules. Keep them separate unless your client/authority explicitly approves combined design.

- Oversizing leading to stagnant water. A 20 m³ tank for 1 m³/day demand will sit idle for 20 days; biofilm and odor develop in KSA heat. Upsize the daily activity (irrigation, process water) or reduce tank.

- No manhole access planned. Mandatory quarterly–semi-annual cleaning requires technician entry. Ensure manhole is reachable by truck, roof has safe stairs, and removal/replacement does not require complex rigging.

- Poor base preparation. Uneven ground, unsealed concrete, or no proper foundation = slow leaks within months. Budget for a proper 150 mm reinforced concrete pad.

- Ignoring vent/overflow design. Vents must filter dust; overflows must drain safely without backflow. Neglecting these causes contamination and water quality failure.

- Choosing single tank when multi-tank strategy is better. One 20 m³ tank must shut down for cleaning; facility loses supply. Two 10 m³ tanks cost ~10% more but provide redundancy.

- No cleaning/maintenance access plan. Some rooftops are too narrow, or crane cannot reach. Verify installation logistics before purchase.

- Selecting tank based on lowest price alone. SASO-GSO-1831 compliance, NSF certification, material thickness, and warranty vary. A “cheap” tank may fail in 5 years; a compliant tank lasts 20+.

- Forgetting seasonal peaks. A villa uses 0.6 m³/day in winter but 1.2 m³/day in summer (garden watering). Size for summer demand, not annual average.

- No pump/pressure specification. Tank size must match inlet pressure and flow rating. A tank sized for 15 m³ but fed by a 1 m³/hour pump fills in 15 hours = operational lag. Confirm pump capacity aligns with tank refill rate.

FAQs

Q1: What size water tank do I need for a villa in Saudi Arabia?

A: Use this formula: Occupancy (people) × 100–150 L/person/day × Storage days (typically 2) × Contingency (1.2–1.3) = Tank capacity.

Example: 5 people × 120 L/day × 2 days × 1.25 = 1.5 m³ recommended.

If the villa has a garden, add 30–50% more. If supply is intermittent, use 3–5 storage days instead of 2. Confirm actual daily consumption with your water meter; this is an estimate.

Q2: How many days of water storage should I keep in Saudi Arabia?

A: For reliable municipal supply (Riyadh, main cities): 1–2 days is adequate. For areas with intermittent supply (some suburban/rural areas, coastal zones during peak hours): 3–5 days is recommended. For remote/critical industrial sites: 5–7 days to buffer delivery uncertainty.

Check with your local water authority for supply reliability in your specific neighborhood.

Q3: Is it better to use one big tank or two smaller tanks?

A: Two smaller tanks are usually better for villas and factories in Saudi Arabia. Reasons:

- One tank can be offline for mandatory quarterly cleaning without supply loss

- Better water turnover (less stagnation risk in heat)

- Load distribution on roof/foundation

- Easier to service and replace components

Trade-off: Two 10 m³ tanks cost ~10% more than one 20 m³ tank. The extra cost is worth the reliability in KSA’s climate.

Q4: Can I place an FRP tank on a roof?

A: Yes, but verify structural capacity first. Typical villa roofs support 5–10 kN/m². A 10 m³ FRP tank weighs ~12 tonnes (12 kN). Confirm with a structural engineer. If roof cannot support it, use ground placement or split into multiple smaller tanks. Also install a shade structure to reduce internal water temperature.

Q5: How do I size a tank for a factory?

A: Separate the water into components:

- Domestic: Staff count × 50 L/person/day

- Process: Based on production rate (contact machinery suppliers for specs)

- Washdown: Area × estimated cleaning intensity (50–100 L/m²/day)

- Sum total and multiply by storage days (typically 3–5 for industrial)

Example: 40 staff (2 m³) + 8 m³ process + 2 m³ washdown = 12 m³/day × 3 days = 36 m³ base tank size. Add 20–30% contingency for a final 45 m³ recommendation.

Q6: Do I need a separate fire water tank?

A: Usually yes. Fire water is specified separately by the fire authority or client based on hazard classification and occupancy. Saudi Civil Defense regulations often require 40 m³+ for large facilities. Do not combine fire water with potable/process storage unless explicitly approved by the authority. Consult your fire safety engineer for fire tank sizing.

Q7: Does heat change the required tank size?

A: Indirectly. KSA’s heat (45–50°C+) accelerates biofilm growth in stagnant water; it does not increase water demand per person. However, it makes tank sizing strategy more critical: oversizing risks stagnation; you must avoid that. Size based on actual demand + storage days, then install shade to reduce water temperature and improve hygiene.

Q8: How often should I clean a potable water tank?

A: Minimum 1–2 times per year per NWC guidelines. In KSA’s hot, dusty climate, quarterly (every 3 months) is recommended for rooftop tanks, especially in summer. This is one reason multiple smaller tanks are better than one large tank: you can clean one while the other serves supply.

Conclusion

Choosing the right FRP water tank size in Saudi Arabia is a straightforward calculation, not a guessing game. Start with daily demand (occupancy × consumption rate), choose storage days based on supply reliability, add a contingency buffer, verify turnover to prevent stagnation, and confirm installation constraints. For villas: expect 1–5 m³ capacity (2 storage days typical). For factories: 20–100+ m³ (3–5 days typical), depending on process intensity.

The formula works. The key is gathering accurate inputs: occupancy, daily consumption, storage autonomy required, and physical space available. Once you have these, sizing becomes a straightforward engineering exercise.

Key takeaway: Two smaller tanks are better than one large tank in Saudi Arabia. They provide maintenance access, better water turnover in the heat, and reliability without supply loss during cleaning.

Call to Action

Sizing a water tank correctly saves money, prevents outages, and ensures water hygiene for your villa or facility. If you need help calculating the right FRP tank size for your specific location and usage, or if you want to verify your calculations before requesting a quote, Pioneers Fiberglass Co. Ltd. can assist.

Request a Quote with your site details (location, occupancy, daily usage estimate, available space). Our engineers will size the tank and recommend the best configuration for KSA climate and installation constraints.

TABLES (All Tables Summary)

Table 1: Sizing Inputs and Sources

| Input | Typical Source | Notes / Risks |

|---|---|---|

| Daily water consumption rate | Metered water bill, or 100–150 L/person/day estimate | KSA national average is 102 L/day per capita (2023), but villas with gardens/guests may reach 150+ L/day |

| Occupancy count | Villa: number of residents; Factory: employee headcount | Varies seasonally (guest surges, production shifts); size for peak, not average |

| Storage autonomy (days) | Water authority supply reliability, or delivery schedule predictability | 1–2 days for reliable supply; 3–5 days for intermittent; 5–7 days for remote/critical process |

| Space/footprint constraint | Structural engineer (roof load), or site measurement (ground area) | Rooftop weight limits often <10 kN/m²; confirm before purchase. Ground placement requires drainage slope. |

| Turnover requirement | Daily demand ÷ Tank capacity | Aim for ≥70% daily turnover to prevent stagnation in KSA heat |

Table 2: Villa Sizing Scenarios (KSA)

| Villa Scenario | Occupancy | Daily Use Drivers | Suggested Capacity | Storage Days | Notes |

|---|---|---|---|---|---|

| Small villa, 3 occupants, no garden | 3 persons | Toilets, showers, laundry, kitchen, cleaning | 0.5–1.0 m³ | 2 | ~90–100 L/person/day. Adequate for compact villa. |

| Medium family villa, 4–5 occupants, small garden | 5 persons | Toilets, showers, laundry, kitchen, modest watering | 1.0–2.0 m³ | 2 | ~100–120 L/person/day. Typical Riyadh villa. |

| Large villa, 6+ occupants, large courtyard/garden | 6–8 persons | High toilet/shower frequency, laundry, outdoor watering (seasonal) | 2.5–5.0 m³ | 2–3 | ~120–150 L/person/day including garden. Summer peak can exceed 200 L/person/day. |

| Coastal villa (Jeddah/Dammam), 5 occupants | 5 persons | Same as above + salt spray impacts | 1.5–2.5 m³ | 2–3 | FRP advantage evident. Intermittent supply common in coastal areas; consider 3-day buffer. |

Table 3: Factory Water Drivers and Estimation

| Factory Type | Water Drivers | How to Estimate | Common Mistakes | Notes |

|---|---|---|---|---|

| Small food processing (20–50 staff) | Domestic: 50 L/person/day; Process: 2–5 m³/day; Washdown: 1 m³/day | Staff × 50 + production history + facility area | Forgetting boiler feed water; underestimating washdown | Typical total: 5–15 m³/day. 2–3 day buffer typical. |

| Textile/garment (100–200 staff) | Domestic: 50 L/person/day; Wet processing: 100–150 L/kg fabric; Cooling: 5–20 m³/day | Staff + daily fabric kg × process rate; request dye machine specs | Overestimating without production schedule; ignoring seasonal changes | Typical total: 20–50 m³/day. High variability. 3–5 day buffer. |

| Pharmaceutical/chemical (small batch, 50 staff) | Domestic: 50 L/person; Process: 10–30 m³/day (cooling, reactions); Washdown: 2–3 m³/day | Consult process engineer; cooling often recycled so fresh supply lower | Confusing recycled circulation with fresh demand; ignoring chemical compatibility | Typical fresh water: 10–20 m³/day. 5–7 day buffer critical (supply loss halts production). |

| Logistics/warehouse (100–150 staff) | Domestic: 50 L/person/day; Cleaning: 3–8 m³/day; Landscaping/dust control: 2–5 m³/day | Staff + facility area (50–100 L/m² for cleaning) | Underestimating cleaning (dusty KSA); forgetting landscape | Typical total: 10–20 m³/day. 2–3 day buffer adequate. |

Table 4: Oversizing vs Undersizing Trade-offs

| Oversizing Risks | Undersizing Risks |

|---|---|

| Stagnation: In Saudi heat, water >10 days old develops biofilm; quarterly cleaning adds cost | Service Interruption: Villa loses water mid-day; factory halts; emergency tanker delivery (SR 200–400/trip) |

| Higher capex: 20 m³ tank costs ~40% more than 15 m³ | Pump stress: Low pressure/cavitation damages pump; reduces lifespan |

| Footprint burden: Rooftop limits solar/other use; ground tanks consume courtyard | Supply risk: Delayed delivery = facility failure; no redundancy for maintenance |

| Turnover issue: 1 m³/day demand in 10 m³ tank = 10% turnover → stagnation. Must increase demand or shrink tank | Multiple tanks needed anyway: If you need 5 m³ buffer but choose 3 m³, you buy tankers monthly anyway → size correctly from start |