Introduction

In Saudi Arabia’s extreme desert environment, water storage infrastructure faces relentless challenges. Intense UV radiation, temperatures exceeding 50°C, coastal salt spray in some regions, and high-salinity groundwater all accelerate corrosion in traditional storage systems. Property owners, facility managers, and contractors face a critical decision: fiberglass-reinforced plastic (FRP/GRP) tanks or steel tanks. Both materials promise durability, but their performance diverges dramatically under the Kingdom’s harsh climate. This guide examines the engineering reality of each option, supported by field data and international standards applicable to Saudi conditions, helping you make an informed decision based on climate exposure, maintenance capacity, and long-term investment.

Quick Answer: FRP vs Steel Water Tanks in Saudi Arabia

- FRP water tanks last 20–25 years with minimal maintenance in Saudi conditions; steel galvanized tanks last 20–30 years but require frequent recoating

- Corrosion resistance: FRP wins decisively in coastal areas and salt-spray zones; steel requires expensive protective coatings that degrade every 3–5 years in high heat

- Total maintenance cost: FRP typically costs 15–30% less over 20 years due to zero corrosion repairs and no repainting cycles

- Best for coastal projects: FRP tanks are superior for Red Sea and Persian Gulf locations; steel demands 2–3 year recoating intervals

- Installation speed: FRP lightweight design reduces foundation costs and labor; bolted panels assemble on-site faster than welded steel

- Water quality: Both materials meet Saudi potable water standards (SASO-GSO-1831) when properly certified; NSF/ANSI 61 certification ensures safety

- Upfront cost: Steel sometimes cheaper initially, but FRP delivers better value when total ownership costs are calculated over 20 years

FRP/GRP Water Tanks in Saudi Heat

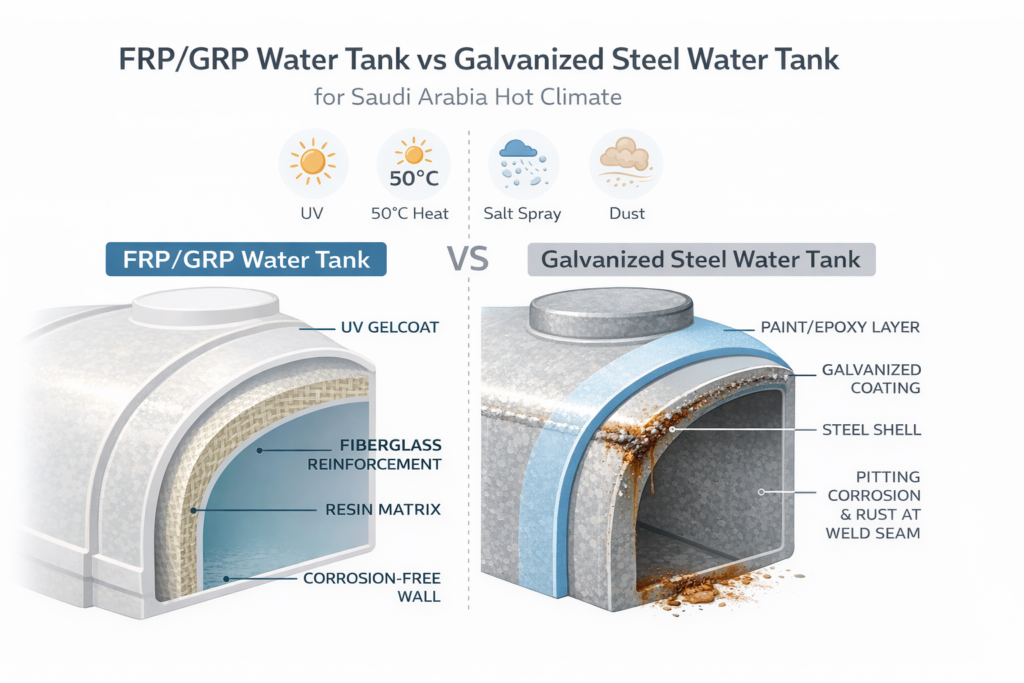

Material Composition and Heat Behavior

Fiberglass-reinforced plastic tanks consist of glass fibers embedded in polyester or vinyl ester resin matrices, laminated to create rigid, waterproof walls. The manufacturing process—typically filament winding or hand lay-up—produces consistent, non-porous surfaces. Export-grade FRP tanks designed for Middle Eastern climates use heat-resistant resin formulations with glass transition temperatures (Tg) deliberately set well above 50°C, ensuring the material remains stable even when ambient temperatures spike.

A critical advantage of FRP is thermal stability through water buffering. The stored water inside the tank acts as a passive heat sink, moderating internal temperature fluctuations and preventing material softening. Field experience in the GCC confirms that properly designed FRP tanks maintain structural integrity throughout Saudi Arabia’s summer months without thermal deformation or stress-induced cracking.

UV and Sunlight Exposure

Saudi Arabia receives intense solar radiation year-round, with UV-A, UV-B reaching the surface unobstructed. Early concerns about UV degradation of FRP are largely resolved through gel-coat technology. Modern tanks use UV-stabilized resin systems and protective gel-coat layers (typically 0.5–1 mm) that absorb UV photons before they penetrate deeper fibers. Surface discoloration and minor chalking may occur after years of exposure, but structural fibers remain protected because UV damage is primarily a surface-level phenomenon; the glass reinforcement acts as a barrier preventing UV from reaching internal resin layers.

Long-term field tests in extreme climates demonstrate that quality export-grade FRP tanks experience minimal mechanical property loss over 20+ years of outdoor exposure.

Corrosion and Salinity

Unlike metallic tanks, FRP does not participate in electrochemical corrosion because it is non-conductive and chemically inert to chloride ions, sulfates, and mineral-laden water typical of Arabian groundwater. In coastal regions near the Red Sea or Persian Gulf—where salt spray is a primary concern—FRP tanks demonstrate unmatched durability. Galvanized steel in the same environment requires protective coating reapplication every 2–3 years; FRP needs none.

Water Quality Preservation

FRP tanks certified to NSF/ANSI 61 (international potable water standard) do not leach taste, odor, or color-altering compounds into stored water, regardless of mineral content or pH variations in Saudi groundwater (typically pH 7.8–8.6, TDS >1000 mg/L). The resin system is chemically stable across the full range of water conditions encountered in the Kingdom.

Maintenance Reality

FRP tanks require minimal intervention. Annual visual inspection of external surfaces, periodic cleaning to remove dust and salt deposits, and bolt torque verification suffice for most applications. No internal coating maintenance or protective paint reapplication is needed. Even in aggressive coastal environments, maintenance is limited to rinses with fresh water and routine fastener checks.

Steel Water Tanks in Saudi Heat

Material Selection and Corrosion Mechanisms

Steel water tanks are manufactured from carbon steel, galvanized steel, or stainless steel. The corrosion performance varies dramatically by type:

- Galvanized steel (zinc-coated, 70–150 µm coating): Designed to sacrifice zinc preferentially, protecting underlying steel. Typical lifespan in temperate climates is 20–30 years; in Saudi Arabia’s heat and salt exposure, this range contracts significantly.

- Stainless steel (304 or 316 grade for potable water): Higher corrosion resistance than galvanized but substantially more expensive. Lifespan can exceed 50 years with proper care.

Temperature Impact on Corrosion Rate

Research on steel tank corrosion reveals that for every 10°C increase in ambient temperature, the corrosion rate of bare or coated steel increases by approximately 30%. In Saudi Arabia, where summer temperatures regularly exceed 45°C, this acceleration is severe. The high ambient temperature also weakens and ages protective coatings prematurely, causing brittle failures and local coating breakdown at welds and seams.

Coastal Zone Corrosion

Seawater splash zones (partly immersed, wet-dry cycling) are the most corrosive environment for galvanized steel. Salt spray deposits on tank surfaces, and the wet-dry cycle continuously removes protective zinc corrosion products, exposing fresh zinc to attack. Time to first maintenance for galvanized tanks in such zones is typically 2–3 years; intervals extend to 5+ years only for fully submerged exposure. Many facilities in Gulf coastal areas report complete coating failure requiring major repainting within 3 years, contradicting original design assumptions.

Coating and Lining Requirements

Modern steel tanks often employ multi-layer protective systems: epoxy linings internally and polyester or polyurethane coatings externally. However, maintaining these systems is labor-intensive. Internal inspections must occur every 10 years per API 653 standards (intervals can extend to 17–20 years with specialized lining systems, but at significant cost). In Saudi Arabia’s high-temperature environment, coating degradation accelerates, and repainting cycles often shorten to 3–5 years rather than the standard 7–10 year intervals assumed in temperate climates.

Water Quality Issues

High-mineral groundwater in Saudi Arabia can accelerate internal corrosion of steel tanks, particularly if deposits accumulate and create galvanic couples. Even stainless steel (304 grade) can experience pitting corrosion if chloride ion concentrations exceed design assumptions. Regular internal cleaning and water quality monitoring are necessary to prevent accelerated deterioration.

Maintenance and Operational Burden

Steel tank owners in Saudi Arabia face recurring maintenance obligations: visual inspections every 5 years (externally); internal inspections every 10 years; periodic coating touch-ups or full repainting every 3–5 years; and potential structural repairs for pitting or welding defects. The cumulative labor and material costs over a 20-year period are substantial.

Head-to-Head Comparison Table

Which One Should You Choose? By Scenario

Villas and Residential Properties

For residential water storage, FRP tanks are the pragmatic choice. A typical villa in Riyadh or Jeddah requires a 5–10 cubic meter (kL) tank. An FRP tank of this size costs less upfront than stainless steel, installs quickly, and requires no specialized maintenance. Homeowners can perform simple visual checks annually without expert intervention. In coastal villas near the Red Sea, FRP is strongly preferred because steel tanks in salt-spray environments demand professional recoating every 3 years—a recurring expense that rapidly exceeds FRP’s initial purchase price.

Industrial and Municipal Sites

Large-scale installations (50+ kL) at industrial facilities or municipal water authorities benefit from detailed TCO analysis. If on-site maintenance capability exists and budget allows, high-quality stainless steel (304 grade) can justify the investment through longer lifespan. However, most industrial projects in Saudi Arabia now specify FRP tanks for primary storage and steel tanks only for specific high-temperature or specialized chemical applications. FRP modular design also permits phased capacity expansion at lower cost than welding additional steel sections.

Coastal Regions (Red Sea, Persian Gulf)

Coastal installations face the harshest corrosion environment. Salt-spray deposition and wet-dry cycling mean galvanized steel requires protection reapplication every 2–3 years. FRP tanks eliminate this recurring burden entirely. For Jeddah, Dammam, and other Gulf ports, FRP is financially and operationally superior, saving 30%+ of lifecycle costs over 20 years.

Remote or Low-Maintenance Sites

In remote desert locations with limited access to maintenance contractors, FRP tanks are preferable. A tank in a Rub’ al Khali oil field or remote agricultural site cannot be easily serviced. FRP’s “set and forget” characteristics make it ideal when professional maintenance visits are infrequent and costly.

Installation & Maintenance Best Practices (KSA)

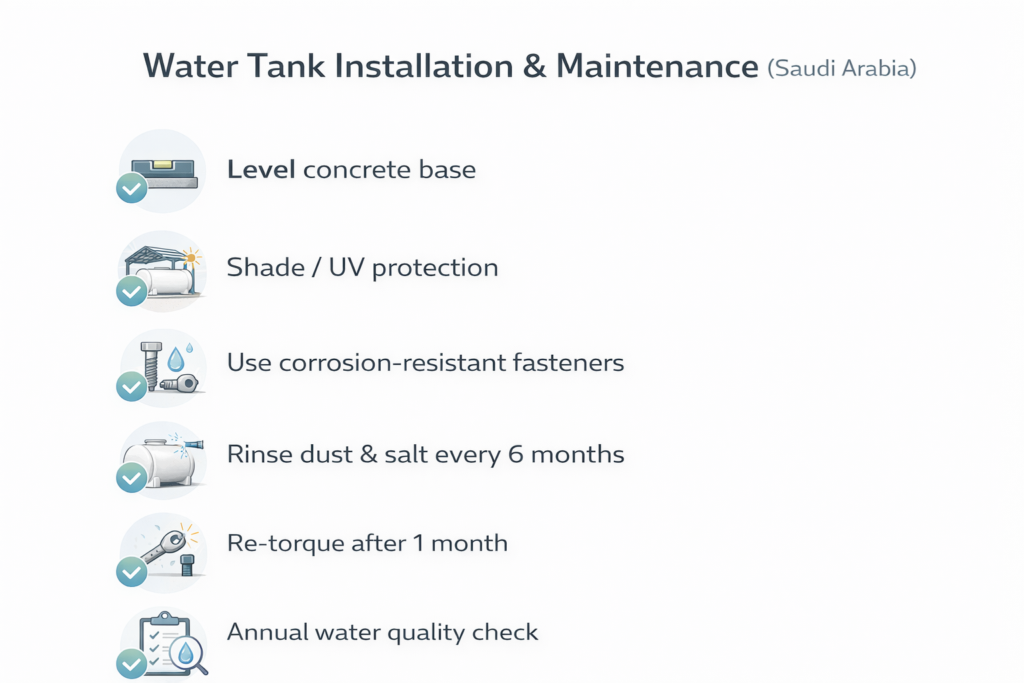

Foundation and Base Preparation

Both FRP and steel tanks require a level, well-compacted foundation. For FRP tanks, the foundation must distribute loads evenly across the bolted base ring to prevent localized bending and stress concentration. Uneven settling can cause seal failure at flanged connections. Recommended practice: concrete pad, 150–200 mm thick, reinforced with mesh, sloped slightly for drainage. The surrounding area should drain away from the tank to prevent water pooling, which accelerates external corrosion (for steel) and biological growth (for both materials).

UV and Heat Protection Measures

While FRP’s gel coat provides UV protection, shade structures extend tank life and reduce internal water temperature in extreme heat. In Riyadh, where summer temperatures exceed 50°C, installing a simple shade frame over the tank maintains water temperature 5–10°C cooler, improving water quality for consumption and reducing thermal stress on FRP or steel equally. For metal tanks, shade also slows coating degradation.

Fittings, Gaskets, and Fasteners

All wetted components must comply with SASO-GSO-1831 and Saudi drinking water standards. Use stainless steel (316 grade) fasteners and NSF 61 certified gaskets. Avoid galvanized fittings on FRP tanks; zinc can leach if contact with gasket material is prolonged. Torque bolts to manufacturer specifications during installation and re-check after the first month of operation; thermal cycling may loosen fasteners.

Cleaning Schedule

FRP tanks: Rinse externally with fresh water every 6 months to remove dust, salt deposits, and biological films. Avoid abrasive scrubbers; soft brushes suffice. Internal cleaning is rarely needed unless biological growth appears (unusual for properly covered tanks).

Steel tanks: Internal cleaning and inspection every 12 months. External coating inspection every 5 years; if coating damage is visible, schedule repainting within 1 year to prevent rust propagation. In coastal zones, increase inspection frequency to every 2–3 years.

Water Quality Monitoring

Test stored water annually (pH, total dissolved solids, turbidity, bacterial count). High mineral content or acidity accelerates internal corrosion in steel tanks. FRP tanks are resilient to water quality variations but benefit from annual pH testing to ensure compliance with WHO/Saudi standards.

Common Mistakes to Avoid

- Underestimating maintenance costs for steel. Many project teams select steel for lower upfront cost, then encounter surprise repainting bills. Always calculate 20-year TCO including coating maintenance.

- Poor foundation preparation. Uneven ground settling causes stress concentration at tank seams and compromises seal integrity for both materials. Take time to prepare a level, compacted base.

- Inadequate ventilation above tank. Poor airflow accelerates biological growth in stagnant water and hastens corrosion of steel tank external surfaces. Ensure shade structures do not seal the tank completely.

- Mixing metal fasteners across materials. Using galvanized bolts on stainless fittings (or vice versa) creates galvanic corrosion. Specify compatible grades (all 316 stainless, or all nylon/plastic for FRP).

- Neglecting water quality testing. High salinity or acidity in stored water accelerates internal corrosion. Monitor water chemistry annually to detect issues early.

- Ignoring coastal salt spray risk. If within 2 km of seacoast, assume salt-spray exposure. For steel tanks, budget aggressive recoating cycles; FRP handles salt spray without intervention.

- Skipping initial coating inspection for steel. Small coating defects expand rapidly in Saudi heat. Catch and repair coating damage within weeks, not months.

- Installing without shade protection. Direct sun accelerates UV aging of any external coating. A simple shade frame (even partial) extends tank life.

- Deferring fastener torque checks. Thermal cycling during installation loosens bolts. Re-torque after 1 month to prevent slow leaks.

- Purchasing non-certified tanks. Only specify tanks with NSF 61 certification (potable water) or equivalent SASO compliance. Generic tanks may leach contaminants.

FAQs

Q1: How long will an FRP water tank last in Saudi Arabia’s heat?

A: FRP tanks designed for Middle Eastern climates typically last 20–25 years with minimal maintenance. Manufacturers often provide 25-year warranties. Actual lifespan extends beyond this if the tank remains well-maintained (annual cleaning, fastener checks, no physical damage). The heat itself does not degrade FRP because the internal water temperature rarely exceeds the resin’s glass transition temperature, and gel-coat UV protection resists sunlight exposure.

Q2: Will a steel water tank rust faster in Saudi Arabia than in Europe?

A: Yes, significantly faster. Corrosion rate increases approximately 30% for every 10°C temperature rise. Saudi summer temperatures (45–50°C) versus European temperatures (15–25°C) create a 60–90% acceleration in corrosion rate for steel. Additionally, in coastal regions, salt-spray exposure requires recoating every 2–3 years, compared to 7–10 years in temperate coastal zones.

Q3: Are FRP tanks safe for drinking water?

A: Yes, when NSF/ANSI 61 certified. This certification confirms that the resin and all tank components do not leach harmful chemicals into drinking water across the full pH range of potable water (pH 5–10). Saudi Arabia also recognizes GSO (Gulf Standardization Organization) standards for water storage. Always purchase tanks with one of these certifications.

Q4: What is the total cost difference between FRP and steel tanks over 20 years?

A: FRP typically costs 15–30% less over 20 years when accounting for maintenance. A galvanized steel tank may cost 10–20% less initially, but repainting every 3–5 years in Saudi climate, internal inspections, and potential corrosion repairs eliminate any savings by year 10. Stainless steel tanks are 40–60% more expensive upfront and offer no cost advantage unless lifespan extends beyond 30 years.

Q5: Can FRP tanks be installed in coastal areas like Jeddah or Dammam?

A: FRP tanks excel in coastal areas. Unlike steel tanks, which suffer salt-spray corrosion and require expensive 2–3 year recoating cycles, FRP tanks are immune to electrochemical corrosion from chloride ions. They perform reliably in seawater splash zones without protective coating reapplication.

Q6: Which tank material is lighter and easier to install?

A: FRP tanks are significantly lighter (5–10 kg per cubic meter of storage capacity) compared to steel (50–80 kg per cubic meter). The lighter weight reduces foundation requirements and permits faster assembly with bolted modular sections. Steel tanks require heavy lifting equipment, precise welding, and longer on-site erection time.

Q7: Do FRP tanks need shade protection in the Saudi sun?

A: While FRP’s gel coat provides UV resistance, shade structures are recommended to reduce internal water temperature (by 5–10°C) and extend tank life. In direct sun at 50°C ambient, internal water temperature can reach 55–60°C; shade keeps it below 50°C, benefiting both water quality and material longevity.

Q8: What maintenance does a steel tank require in Saudi Arabia?

A: External visual inspection every 5 years; in coastal areas, every 2–3 years. Internal inspection every 10 years (can extend to 17–20 years with advanced linings, but cost is high). Repainting/recoating every 3–5 years in Saudi heat due to accelerated coating degradation. FRP requires annual visual checks and cleaning only—no painting or coating work.

Conclusion

The engineering evidence is clear: for most applications in Saudi Arabia and the GCC, FRP water tanks outperform steel tanks in durability, maintenance burden, and total cost of ownership. The Kingdom’s extreme heat, coastal salt spray in certain regions, and high-salinity groundwater accelerate steel’s corrosion and coating degradation far beyond rates assumed in temperate climates. FRP tanks, by contrast, are fundamentally resistant to these stressors. They last 20–25 years with minimal intervention, cost 15–30% less to own over two decades, and require no specialized maintenance expertise.

Steel remains a valid choice only in scenarios where very large capacity, specialized industrial requirements, or existing on-site maintenance infrastructure justify the recurring recoating and inspection burden. For residential villas, commercial facilities, industrial sites in non-coastal regions, and particularly for coastal projects, FRP is the rational engineering choice.