Introduction

This guide explains FRP diesel storage tanks in Saudi Arabia—the main safety standards, bunding, venting, and inspection best practices for industrial sites. Diesel storage tank failure in Saudi Arabia can cause environmental contamination, operational shutdown, and serious safety incidents. Industrial sites—refineries, power plants, generator facilities, logistics hubs, manufacturing plants—depend on reliable diesel supply. The choice of tank material, secondary containment design, and installation practices directly affects safety, compliance, and long-term cost.

This guide addresses FRP (fiberglass-reinforced plastic) diesel storage tanks in KSA context. You will learn which standards apply, how secondary containment and venting work, what FRP compatibility means for diesel, and practical installation/inspection best practices. All recommendations are grounded in NFPA, API, SASO, and international standards. Critical rule: Final design must always be confirmed with your Authority Having Jurisdiction (AHJ), client specifications, and certified HSE engineers. This article provides engineering framework, not approval.

Quick Answer: 9 Key Points on FRP Diesel Tanks in KSA

- Standards vary by jurisdiction: NFPA 30 (spacing, venting), API 650 (tank design), UL/ISO (materials), SASO (Saudi compliance), and local authority specs all apply. No single standard covers everything. Confirm requirements with your AHJ and client before design finalization.

- Aboveground vs underground: Aboveground tanks are faster to install and inspect; underground tanks are space-efficient but require more complex excavation/access design. Both require secondary containment in most jurisdictions.

- Secondary containment is mandatory (almost always): Bund walls or double-wall construction must contain 110% of the largest tank’s capacity. This prevents fuel spills from reaching soil or groundwater. Never skip this step.

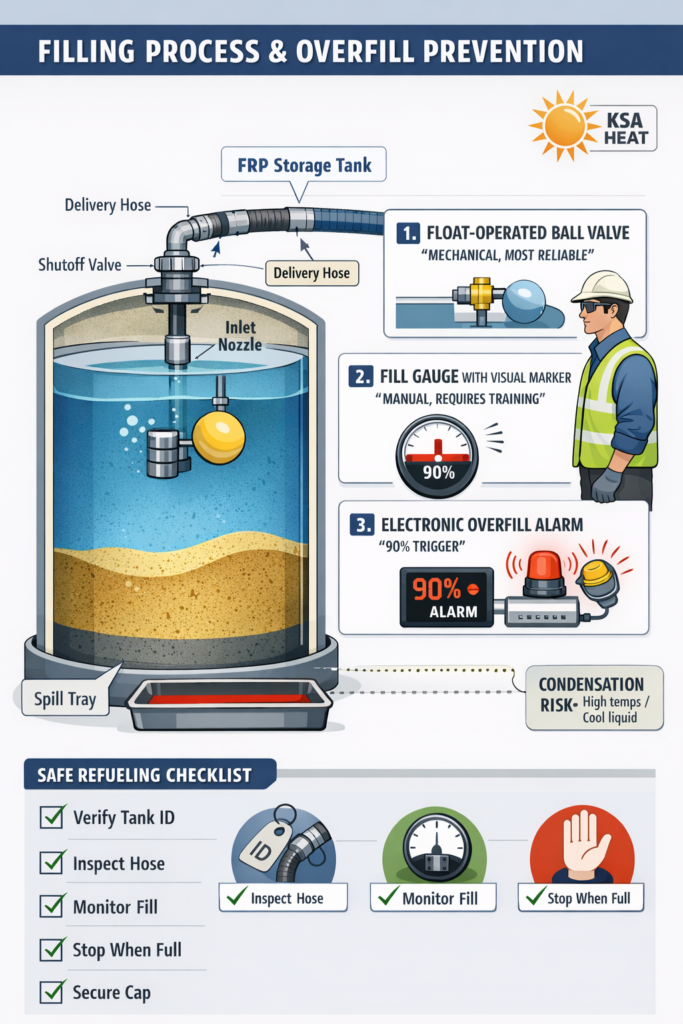

- Venting and overfill prevention are critical safety: Diesel expands in KSA heat; proper venting prevents tank overpressurization. Desiccant breathers reduce water vapor ingress during temperature cycling. Overfill alarms/gauges protect against operator error.

- Fire safety requires specific spacing: Tanks must be separated from buildings, property lines, and other structures per NFPA 30 (typically 5–100 feet depending on tank size and protection level). Confirm distances with local fire authority.

- Grounding/bonding applies when required: If tank piping includes static-conductive hoses or components, grounding to prevent static discharge may be specified by client. Confirm electrical requirements with design engineer.

- Heat and UV protection in KSA: Unshaded FRP diesel tanks must have UV-protective external coating. Shade structures reduce internal temperature (limiting condensation) and extend tank lifespan.

- FRP is compatible with diesel: Isophthalic/terephthalic polyester or vinyl ester resins handle diesel well. No steel corrosion problems in KSA’s salty, hot environment; FRP’s non-corroding nature is a major advantage.

- Inspection and documentation are non-negotiable: Commissioning tests (hydrostatic pressure testing), maintenance logs, annual inspections, and SASO certificates must be in place from day one. Regulatory compliance depends on records.

Diesel Risk Profile in KSA Sites

Heat and Vapor Behavior

Saudi Arabia’s summer temperatures exceed 50°C. Diesel fuel expands as temperature rises—unvented or poorly vented tanks can develop excessive internal pressure, stressing seams and connections. Even small pressure increases (2.5 PSIG typical) can cause rupture or seal failure if not relieved properly.

Temperature cycling (hot day, cool night) drives another hazard: condensation. As warm air enters the tank during refueling and then cools overnight, water vapor condenses into liquid water inside the tank. This water promotes microbial growth and fuel degradation, potentially damaging fuel injection systems.

Leaks and Spills

A pinhole leak in a diesel tank often goes undetected for weeks. In sandy KSA soil, leaked fuel migrates quickly toward groundwater. A 50-liter/day leak undetected for 30 days = 1,500 liters lost and environmental liability incurred. Secondary containment catches these failures before they reach soil or drain systems.

Generator Refueling as High-Risk Activity

Portable fuel trucks delivering diesel to generator sets during peak load/emergency conditions are accident-prone. Hose connections fail, fuel splashes, overfill occurs. Without proper fill-point design and housekeeping, spills are inevitable. Bund walls and spill kits mitigate this risk.

Coastal Corrosion of Metal Fittings

FRP tanks themselves are non-corroding, but metal bolts, flanges, and pipe fittings are vulnerable to salt-spray corrosion in coastal KSA (Jeddah, Dammam, Eastern Province). Specifying stainless steel (316 grade) fittings in salt-spray zones prevents maintenance headaches and unexpected failures.

Human Factors

Overfilling, poor housekeeping (fuel puddles near ignition sources), missing labels, and inadequate training cause incidents. A tank labeled “potable water” but containing diesel; staff unaware of hazard procedures; no emergency shutdown plan—these are real-world failures preventing compliance.

Which Standards Apply?

Tank design, installation, and operation in Saudi Arabia must comply with multiple overlapping standards. There is no single “approved standard”—engineers must integrate requirements from several sources and confirm final design with the Authority Having Jurisdiction (AHJ) and client.

International Codes Commonly Referenced

NFPA 30 (Flammable and Combustible Liquids Code)

Provides minimum spacing distances, secondary containment requirements, venting design, fire protection, and hazard classification. Diesel (Class IIIB liquid) has less stringent requirements than gasoline (Class I/II), but secondary containment and venting still apply in most contexts. NFPA 30 is a US-based code, widely referenced internationally but not law in KSA—check with local AHJ for applicability.

API 650 (Welded Steel Tanks)

Covers tank design, materials, fabrication, testing, and inspection for large capacity aboveground tanks. API 650 does NOT directly address FRP tanks or secondary containment design (that is outside its scope), but engineering principles apply. FRP tanks must meet equivalent structural safety standards per their materials (e.g., ASME RTP-1, ISO standards listed below).

UL Standards (UL 80, UL 142, UL 2080, UL 2085)

Equipment listing standards for aboveground tanks storing Class IIIB liquids (diesel). UL 142 covers shop-fabricated aboveground storage tanks. UL 2085 addresses protected aboveground tanks with secondary containment. Tanks bearing UL listing are certified to meet defined safety and performance criteria.

ISO/ASME Standards for FRP Tanks

- ASME RTP-1: Reinforced Thermosetting Plastic Corrosion Resistant Equipment

- ASTM D3299: Standard Specification for Filament-Wound Glass-Fiber-Reinforced Polyester Chemical-Resistant Tanks

- BS 4994 / EN 13280: British/European standards for FRP tanks and plastic tanks

These standards define FRP material selection, laminate design, pressure/structural testing, and quality control specific to composite construction.

Local Compliance in Saudi Arabia

SASO (Saudi Standards, Metrology and Quality Organization)

SASO Technical Regulation for Tanks – Part 1 (Petroleum Products Transportation Tanks) governs tank design and certification in Saudi Arabia. Key requirements:

- Tank manufacturer must be registered with SASO

- Certificate of Conformity required; issued by SASO or approved notified body

- Tanks must comply with applicable Saudi Technical Regulations and referenced standards (ISO/IEC 17067 assessment model)

- Arabic labeling with supplier name, chassis number, and safety information

- Type approval process required before commercial sale

If designing a diesel tank for Saudi Arabia, SASO registration and Certificate of Conformity are mandatory.

Saudi Civil Defense and Fire Authority

Fire safety separation distances, bund wall height, drainage, extinguisher placement are specified by local fire authorities. Standards vary by emirate/region. Confirm specific requirements with your local Civil Defense office (in Riyadh, Jeddah, Dammam, etc.) and client project specifications.

Client and Authority Specifications

Large industrial projects (refineries, power plants, ARAMCO facilities) often specify ARAMCO Engineering Standards (SAES) or equivalent, which may exceed SASO/NFPA minimums. Always request the project’s “Authority Having Jurisdiction (AHJ)” document and compliance matrix from your client.

Documentation Typically Requested for Compliance

Before purchasing or installing a diesel storage tank in KSA, you will need to provide:

- Design drawings: Piping layout, inlet/outlet/vent/drain placement, secondary containment bund dimensions

- Material datasheets: Tank material (FRP resin type, fiberglass grade), gaskets, fasteners, test certifications

- QA/QC documentation: Material certs, manufacturing inspection reports, hydrostatic test results

- Installation method statement: Step-by-step installation procedure including safety measures, equipment, trained personnel

- HSE risk assessment: Hazard identification, controls, emergency response plan

- Operation & Maintenance (O&M) manual: Inspection intervals, maintenance procedures, safety procedures, spare parts list

- Compliance matrix: Showing how the tank design meets SASO, NFPA 30, API, client, and local AHJ requirements

Tank Configuration Options (What to Choose)

Diesel storage comes in several configurations. Each has distinct safety controls and KSA climate tradeoffs.

Configuration Comparison Table

| Configuration | Best For | Key Safety Controls | Typical Mistakes | KSA Notes |

|---|---|---|---|---|

| Single-wall aboveground horizontal tank | Generator fuel, small industrial site, temporary storage | External bund/dike wall; vent + drain; overfill gauge; spill kit | No secondary containment; poor vent routing; overfill risk | Fast to install; but bund design critical in sandy soil. Heat causes vapor buildup; ventilation essential. |

| Single-wall aboveground vertical tank | Larger capacity (fixed installation), better space efficiency | Bund wall; emergency vent; level indicator; safe fill access | Under-sized bund; fill point exposed; inadequate access for cleaning | Vertical tanks more stable in wind; but require deeper bund = higher cost in KSA rock/hard soil. |

| Double-wall (tank-in-tank) aboveground | Premium safety, environmental protection, leak detection | Interstitial space monitoring; internal tank inspection port; outer wall sensors | Complex design; difficult to inspect interstitial space; cost | Secondary containment built-in; reduces bund wall size needed. Thermal cycling may stress outer shell; thermal expansion gaps required. |

| Underground single-wall with external bund | Space-constrained sites (courtyard), ground-level access | Excavated bund/liner (HDPE or concrete); leak detection; vent head above grade | Water table interference; difficult access for inspection/maintenance; corrosion risk | KSA: high water table in some coastal areas (unfavorable); excellent UV/heat protection. Remote sites often prefer underground. |

| Day tank (small, 500–5000 L) + bulk tank (feeder) | Generator sites with automatic transfer, production facilities | Day tank has tight secondary containment + overfill alarm + gravity feed to generator; bulk tank has bund/secondary | Mixing configurations; unclear transfer procedure; overfill during bulk transfer | Common in large facilities; day tank sits near generator (heat exposure); bulk tank remote (cooler). Both require vents. |

Secondary Containment & Spill Control Best Practices

Why Secondary Containment Matters

Secondary containment is not optional. It is the engineered barrier preventing environmental liability. A single-wall tank without containment has a 100% spill probability if the tank fails.

Containment Sizing and Design

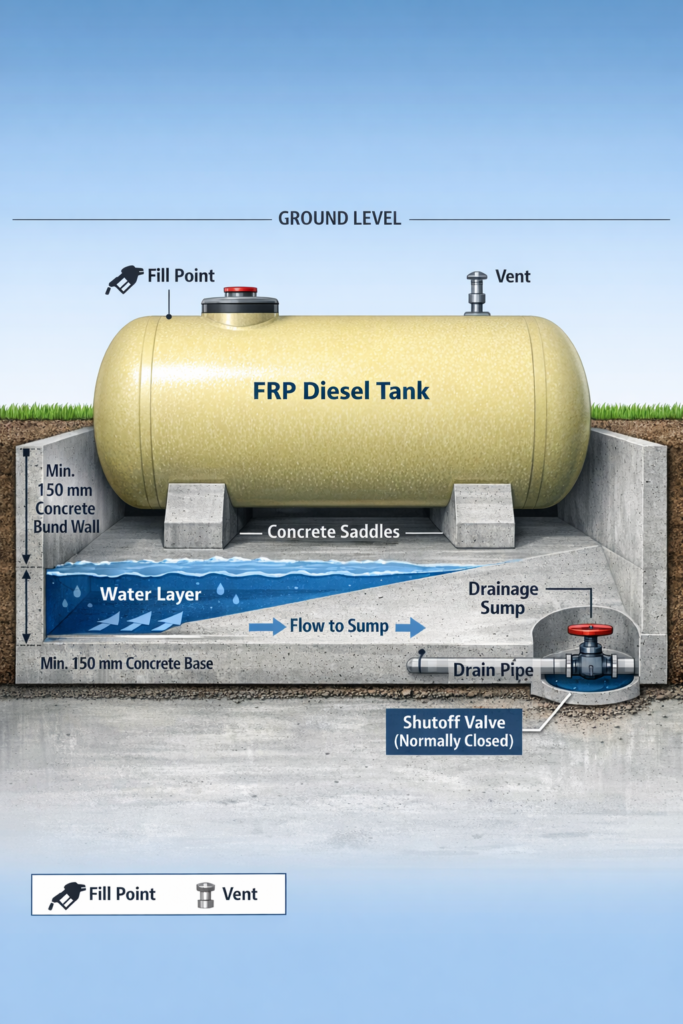

- Capacity: Containment must hold at least 110% of the largest single tank’s maximum capacity. This 110% accounts for foam/water spray during fire suppression.

- Material: Must be impermeable to diesel fuel and compatible with long-term fuel exposure. Options include:

- Concrete bund wall with sealed interior (common in KSA industrial yards)

- HDPE (high-density polyethylene) liner in earthen bund (more flexible, seepage control)

- Double-wall tank construction (containment built into tank)

- Dike walls (concrete block, compacted earth with clay/plastic membrane)

- Surface: Impermeable base must prevent fuel penetration to groundwater. Concrete minimum 150 mm thick, sloped for drainage (1–2% gradient).

Drain Management

- Critical rule: Drainage valves in the secondary containment must remain closed except during controlled drainage events.

- Disposal: Any fluid accumulated in the secondary containment (rain water, spilled diesel, etc.) must be tested before discharge. Contaminated water cannot be drained to stormwater or soil directly.

- Pump and tank: Manual or automatic pump removes water/fluid from bund, into a holding tank, then to wastewater treatment.

- No general storage: The bund space cannot be used for tool racks, material storage, etc. It must remain clear for spill containment.

Spill Kits and Housekeeping

- Spill kit placement: Within 15 m of the fill point. Should include absorbent pads, sorbent powder, disposal bags, and instruction sheet.

- Daily visual check: Look for fuel odor, stains, visible drips. Address immediately.

- Bund inspection: Monthly check for cracks, water accumulation, debris that could block drainage.

- No pooling water: Standing water in the bund promotes rust (on metal items) and creates safety hazards.

Safe Fill Point Design

- Protected fill connection: Elevated, away from foot traffic and impacts. Covered cap when not in use.

- Spill tray: Small secondary containment (0.5–1 m³) directly under fill nozzle catches splash.

- Hose management: Fuel delivery hoses should be pressure-tested and inspected before each use. Worn hoses leak.

- Manual shutoff valve: Between tank and fill point allows quick isolation if needed.

- Signage and labeling: “DIESEL FUEL” clearly marked; SDS (Safety Data Sheet) posted nearby; emergency contact phone number visible.

Venting, Overfill, and Safe Filling

Why Venting Matters

As fuel is drawn from the tank (generator running, fuel delivery), air must enter to replace it. As fuel is added (refueling), air must exit. Without venting:

- Vacuum can develop, collapsing the tank or preventing fuel flow

- Pressure can build, stressing seams and rupturing the tank

- Water vapor and condensation accumulate, degrading fuel quality

Normal Vent Sizing and Design

Vent sizing depends on fuel withdrawal rate. A generator consuming 100 liters/hour requires a vent sized to pass that flow without excessive back-pressure. Undersized vents cause tank collapse or cavitation in the fuel pump.

Normal vents are typically 1–2 inch diameter pipes with:

- Height: Termination at least 12 feet above ground (NFPA recommendation) to dilute vapors

- Screen: Prevents insect entry and rain ingress; 0.5 mm mesh typical

- Anti-siphon device: Prevents siphoning loss if tank is breached

- Desiccant breather (recommended for KSA): Silica-gel or molecular sieve breather absorbs water vapor from incoming air, reducing internal condensation. Important in KSA’s hot/humid climate.

Overfill Prevention

Fill connections should be arranged to prevent overfilling:

- Float-operated ball valve: Stops flow when tank is full (mechanical, most reliable)

- Fill gauge: Visual indicator showing tank level; operator can watch and stop when full

- Overfill alarm: Electronic sensor triggers audible/visual alarm at 90% capacity (useful for automated tanker trucks)

- Manual restraint: Fuel truck driver trained to stop filling when fuel reaches nozzle spillway

Safe Refueling Procedure (High-Level)

- Park fuel delivery truck at safe distance (no ignition sources, engine off)

- Verify tank identification label (DIESEL, not water or other liquid)

- Connect delivery hose; inspect for cracks/damage before use

- Open fill connection slowly (prevents splash and pressure spike)

- Monitor fill gauge or use overfill alarm as reference

- Stop when fuel reaches nozzle spillway; do not overfill

- Disconnect hose slowly to prevent drip

- Replace and secure fill cap immediately

- Inspect spill tray/area for leaks; clean spill kit if used

Fire Safety & Site Layout (KSA Reality)

Separation Distances and Access

Fire authorities specify minimum distances to reduce fire spread risk and allow firefighter access.

NFPA 30 provides guidance (typical values for Class IIIB/diesel tanks):

- From property line: 15–50 feet (varies by tank size and protection level)

- From buildings on same property: 50–100 feet (varies by tank size)

- Between adjacent tanks: Minimum 3 feet (0.9 m), but typically 1/6 × sum of adjacent tank diameters

Critical: These are NFPA minimums. Your local Saudi fire authority (Civil Defense in each region) may impose stricter requirements. Always confirm with:

- Your project’s AHJ (Authority Having Jurisdiction) fire department or Civil Defense office

- The client’s HSE manager and project specifications

- ARAMCO standards if project is ARAMCO-related

Ignition Source Control

Near diesel storage tanks, eliminate ignition sources:

- Hot works permit system: Any welding, cutting, or grinding within 50 m must follow hot works procedures (spotter, fire watch, extinguisher on-site)

- No smoking signs: Clearly posted, enforced

- Electrical equipment: Approved for hazardous areas if required by design (consult electrical engineer)

- Lightning protection: Tanks may require earthing/grounding rods to dissipate lightning strikes (confirm with structural/electrical engineer)

Extinguishers and Emergency Response

- Type: B:C rated portable extinguishers (dry powder for flammable liquid fires)

- Placement: Within 15 m of fill point and tank area

- Training: Site personnel must know location and operation

- Inspection: Monthly functionality check; annual professional service

- Emergency response plan: Written procedure for spill/fire scenario; contact numbers for fire service, HSE manager, environmental agency

Signage and Labeling

- Tank label: “DIESEL FUEL” in Arabic and English

- Hazard label: Flammable liquid symbol (per NFPA/ISO standards)

- SDS (Safety Data Sheet) posted in nearby office/control room

- Emergency contact: Local fire service, plant HSE manager, spill response contractor

- Spill kit location signage: “SPILL KIT LOCATION” with arrow

Materials & Hardware for KSA Conditions

FRP Resin Selection for Diesel

Diesel fuel is a mild to moderate chemical exposure. Most FRP resins handle it well if properly selected:

- Isophthalic polyester: “Good” to “Excellent” for diesel; good chemical and weather resistance

- Terephthalic polyester: “Excellent” for diesel; higher cost than isophthalic but superior durability

- Vinyl ester: “Excellent” for diesel; most robust option for long-term storage and temperature cycling

- Orthophthalic polyester: “Not recommended” for diesel; lower chemical resistance

Specify the correct resin during tank procurement. Verify with your tank supplier’s technical datasheet that the tank is manufactured with isophthalic, terephthalic, or vinyl ester resin—not orthophthalic.

UV Protection for Exposed Tanks

FRP exposed to direct Saudi sunlight requires external UV-protective coating. Options:

- Gel coat with UV absorbers: Factory-applied; typical for all commercial FRP tanks

- Polyurethane topcoat: Additional layer applied post-factory for extra UV protection (optional, adds cost)

- Shade structure: Simple metal frame with shade cloth reduces internal temperature 5–10°C; extends tank life; reduces condensation risk

Temperature Cycling and Support Saddles

KSA daily temperature swings (50°C day, 20°C night) cause thermal expansion/contraction in the tank wall and support structure.

- Saddle supports: Should allow slight axial movement; use thermal expansion bearings or PTFE sliding pads (not fixed bolts)

- Piping: Connect via flexible hose (not rigid pipe) to allow thermal movement; prevents stress on tank nozzles

- Fasteners: Stainless steel (316 grade) bolts resist salt-spray corrosion in coastal KSA; cadmium-plated or mild steel fasteners fail in salt spray within 2–3 years

Corrosion-Resistant Fittings (Coastal Sites)

If the tank is within 2 km of seacoast (Jeddah, Dammam, etc.), specify:

- Valve bodies: Stainless steel 316 (not mild steel or aluminum)

- Bolts/fasteners: Stainless steel 316 (not galvanized or cadmium-plated)

- Gauges/instruments: Stainless steel wetted parts

- Gaskets/seals: Viton or EPDM (not natural rubber, which degrades in UV and heat)

Installation Checklist (Step-by-Step)

Phase 1: Planning and Site Assessment

- Confirm tank application (generator fuel, industrial process, emergency reserve)

- Obtain AHJ requirements (local fire authority, Civil Defense, building official)

- Confirm client HSE specifications and project standards

- Identify location (distance to buildings, property lines, ignition sources)

- Assess soil conditions (bearing capacity, water table, chemical compatibility)

- Confirm available utilities (water for hydrostatic test, electrical power for pumps if needed)

Phase 2: Foundation and Base Preparation

- Survey and level site (slope minimum 1–2% for drainage)

- Clear vegetation and loose soil

- Compact base to 95% standard Proctor density (per ASTM D698) if excavation is deep

- Install concrete pad: minimum 150 mm thick, reinforced with rebar, sealed surface

- Allow 7 days concrete curing before tank installation

- Inspect base for flatness: maximum variation 12 mm over tank footprint (critical for tank stability)

Phase 3: Secondary Containment

- Construct bund wall (concrete, compacted earth + membrane, or HDPE liner), sloped 1–2%

- Verify bund capacity = 110% of largest tank volume (calculate before construction)

- Install impermeable lining (if not poured concrete): HDPE 1.5–2 mm thickness, seams welded or overlapped per spec

- Install drainage system: sump pit at lowest point + manual shutoff valve (remains closed except during controlled drainage)

- Test drainage: pour water, verify flow to sump; drain valve operates smoothly

- Inspect for cracks, holes, protrusions (sharp rocks) that could puncture liner

Phase 4: Tank Lifting and Placement

- Identify center of gravity for tank (critical for horizontal tanks)

- Plan lift: use appropriate lifting lugs; crane rated for load + safety factor 4:1 minimum

- Clear lift area of personnel; post spotter to guide operators

- Slowly lower tank onto prepared saddle supports; verify level with transit

- Bolt tank to saddles per manufacturer drawings; torque fasteners per spec (typically 20–50 N·m for stainless bolts)

- Final leveling check: maximum 6 mm variation in support height

Phase 5: Piping, Vents, and Connections

- Install inlet connection (fill nozzle receptacle): elevated, covered, with screen on vent

- Install outlet connection: isolating ball valve + check valve (prevents backflow)

- Install drain valve: low point of tank, with manual shutoff + quick-disconnect coupling

- Install vent line: 1–2 inch diameter, routed to 12+ feet height, with desiccant breather

- Install overflow: routed to secondary containment (not to drain)

- Install level gauge: mechanical float gauge or electronic sensor

- Install overfill alarm (if specified): audible + visual indicator at 90% tank capacity

- Pressure test all piping at 1.5× operating pressure before commissioning (confirm test pressure and procedure with engineer)

Phase 6: Testing and Commissioning

- Perform hydrostatic pressure test per API/ASME standards (typically 1.5 bar for atmospheric tanks)

- Fill tank slowly with water; inspect for leaks at all connections

- Run for 24 hours; check for weeping or cracks

- Drain test water safely (dispose per environmental regs, not to stormwater)

- Visual inspection: check bund for water ingress, tank for damage

- Functional tests: operate all valves, drain shutoff, overfill alarm

- Calibrate level gauge or sensor

- Dry tank interior if needed (consult manufacturer on water removal procedure)

Phase 7: Labeling and Documentation

- Apply tank label: “DIESEL FUEL” (Arabic + English)

- Apply hazard label: Flammable liquid symbol (NFPA/ISO)

- Post SDS (Safety Data Sheet) in nearby office or on tank sign

- Install spill kit signage within 15 m of fill point

- Post fire extinguisher location signage

- Install emergency contact placard (fire service, HSE manager, environmental hotline)

- Provide as-built drawings to client (actual piping, drain/vent locations)

- Provide O&M manual: inspection schedule, maintenance procedures, spare parts list

Inspection & Maintenance Plan (KSA)

Diesel tanks must be inspected regularly to catch leaks and degradation early.

Daily / Weekly Visual Checks (Operator)

- Odor: Any fuel smell near tank? Indicates leak

- Stains: Look for wet patches on bund wall or ground; indicates active leak

- Vent condition: Is vent screen intact and clear (not clogged with dust)?

- Fill cap: Secure and not leaking?

- Spill kit: Present and accessible?

- Emergency contact sign: Readable and current?

Monthly Inspections (HSE/Maintenance)

- Bund interior: Check for accumulated water, sediment, debris

- Drain valve: Test operation (open/close slowly); ensure it closes completely

- Tank exterior: Walk around; look for cracks, corrosion, loose fasteners

- Piping and connections: Look for seepage or discoloration

- Support saddles: Check for rust, movement, or shifted tank

Quarterly Functional Tests

- Level gauge: Compare manual measurement (sight glass or tape) to electronic gauge; should match within 5%

- Overfill alarm: Test alarm operation (if installed); confirm audible and visual trigger at ~90%

- Vent desiccant breather: Replace if breather is wet or saturated (silica-gel indicates saturation by color change; molecular sieve requires test per manufacturer)

Annual Integrity Inspection

- Tank interior visual (only if required by client): Use mirror/flashlight; check for sediment, water, corrosion

- Pressure test (if specified by client or project standard): Repeat hydrostatic test to verify structural integrity

- Piping test: Pressure test all lines at operating pressure

- Fastener inspection: Check bolt torque; retighten if loose (vibration from generator can loosen bolts)

- SDS and documentation: Update as needed; confirm current revision

- Maintenance log review: Identify trends (increasing water accumulation? Multiple leaks?)

Record Keeping

Maintain a logbook (paper or digital):

- Date, inspected by, findings, actions taken

- Example: “2026-02-15, Ahmad (HSE), vent screen clogged with dust, replaced. Bund clear, no water. All OK.”

- Spare parts inventory: Replacement gaskets, fasteners, desiccant cartridges, absorbent pads

- Service history: Pressure tests, hydrostatic test results, repairs, modifications

Common Mistakes to Avoid

- No secondary containment or undersized bund. A 10 m³ tank requires a bund sized for 11 m³ (110%). Failure to contain a spill creates environmental liability and regulatory fines. Calculate bund size before construction; do not “estimate.”

- Fill point exposed to impacts or rain. Unsecured nozzles get stepped on, backed into by vehicles, or corroded by weather. Elevate fill connection, protect with covers, inspect hoses for damage before each use.

- Vent routed indoors or terminated too low. Vapors not dispersed = explosive atmosphere risk. Terminal height must be 12+ feet above ground (NFPA guidance). Confirm with AHJ.

- No spill kit on-site or too far away. If leak occurs and no absorbent materials are present within 15 m, the spill spreads. Keep kit visible and accessible.

- Mixing stormwater and bund drainage. Contaminated water from the bund must never drain to the stormwater system without treatment. Install separate sump and disposal tank.

- Ignoring generator vibration and pipe stress. Vibrating generator pumps cause movement; rigid pipes crack tank nozzles. Use flexible hose connectors and vibration isolators.

- Direct sun exposure without UV strategy. Unshaded FRP tanks in direct KSA sun age faster. Install shade frame or specify premium UV-protective coating; reduces internal temperature and condensation risk.

- No access clearance for inspection or cleaning. Tank must be accessible for annual visual inspection and (if needed) internal cleaning. Leave at least 1 m clearance around tank for safe movement.

- Missing labels, SDS, or emergency contacts. A new operator seeing “Tank A” does not know it contains diesel. Label clearly; post SDS and emergency contact numbers nearby.

- Relying on “rule-of-thumb” instead of AHJ specs. Every jurisdiction (Riyadh, Jeddah, Dammam) has local fire authority requirements. Confirm distances, bund design, and fire protection with your AHJ in writing before installation.

- Poor training for refueling personnel. Overfill, cross-contamination, and spills happen when operators are untrained. Provide documented training to everyone handling diesel delivery.

- No maintenance logs or incident reporting. Without records, you cannot prove compliance to inspectors. Document everything: inspections, repairs, anomalies, test results.

FAQs

Q1: Are diesel tanks required to have bund walls in Saudi Arabia?

A: Yes, in practice. While SASO and local fire codes vary, secondary containment (bund wall or double-wall tank design) is required by NFPA 30 and almost universally mandated by AHJ and client specifications in KSA industrial projects. A spill without secondary containment creates environmental liability. Always confirm with your AHJ and client before design. The answer is almost always “yes,” so plan for 110% secondary containment capacity from the start.

Q2: Is FRP safe for diesel storage?

A: Yes, FRP is safe for diesel when manufactured with the correct resin. Isophthalic polyester, terephthalic polyester, or vinyl ester resins are fully compatible with diesel. FRP’s non-corroding nature is actually an advantage in KSA’s salty, hot environment compared to steel (which rusts). Avoid orthophthalic polyester for diesel; verify resin type in the tank datasheet before purchase.

Q3: Single-wall vs double-wall diesel tank: which is safer?

A: Double-wall tanks integrate secondary containment into the tank structure, eliminating the need for external bund walls; they are simpler operationally. However, they are more expensive and more difficult to inspect internally. Single-wall tanks with a proper external bund are equally safe if the bund is well-designed and maintained. The choice depends on space constraints and budget. Both are acceptable; confirm your project’s preference with the client.

Q4: How do I prevent overfilling a diesel tank?

A: Use one or more of these controls:

- Float-operated ball valve: Mechanically stops flow when tank is full (most reliable, no electricity needed)

- Fill gauge: Operator watches level and stops when full (requires training and attention)

- Overfill alarm: Electronic sensor triggers alarm at ~90% (good for unattended or automated transfers)

Best practice: Combine a mechanical float valve (primary) with an alarm (backup). Train operators to stop when fuel reaches the spillway nozzle.

Q5: What documents are needed for approval/inspection?

A: Before installation, prepare and have approved:

- Design drawings (piping, bund layout, fill point, drain, vent routing)

- Material datasheets (FRP resin type, gasket compounds, fastener grades)

- Manufacturer’s QA/QC certs (hydrostatic test results, material certs)

- Installation method statement (step-by-step procedure, equipment, trained personnel)

- HSE risk assessment (hazard identification, spill response plan)

- O&M manual (inspection schedule, maintenance procedures, spare parts)

- Compliance matrix (showing how design meets SASO, NFPA, AHJ, client specs)

Provide these to your AHJ and client for review and approval before purchasing the tank.

Q6: Can I place a diesel tank near a generator?

A: Yes, but distance varies. Typical rule: Day tank (small, <5 m³) can be 10–30 m from generator; bulk tank should be 50+ m away. This reduces generator fuel and air intake contamination from spills and minimizes fire spread risk. Confirm separation distances with your AHJ and fire authority. Position the tank upwind of the generator (prevailing wind direction) to reduce vapor drift.

Q7: How does Saudi heat affect diesel tank installation?

A: Heat causes three main effects:

- Fuel expansion: Requires proper venting to prevent overpressurization

- Condensation: Temperature cycling (hot day, cool night) drives water into the tank; use desiccant breathers to reduce moisture ingress

- UV degradation: Unshaded FRP tanks need UV-protective coating or shade structures

Mitigation: Install desiccant breather on vent line; use UV-protective coating or shade; inspect vent screen monthly (KSA dust clogs screens easily); ensure tank drainage slope allows bund water to drain (prevents rust/contamination).

Q8: What maintenance is required for a diesel storage tank?

A: Frequency depends on climate and usage, but typical schedule:

- Daily/weekly: Visual check (leaks, vent condition, spill kit present)

- Monthly: Bund inspection, drain valve test, exterior walk-around

- Quarterly: Level gauge functional test, overfill alarm test, desiccant breather inspection

- Annually: Pressure test, piping test, fastener retorque, interior visual (if accessible), maintenance log review

Keep detailed logs of all inspections and maintenance. This proves compliance to auditors and regulators.

Conclusion

FRP diesel storage tanks are proven, safe, and compliant when designed to applicable standards. In Saudi Arabia’s hot, dusty, salt-spray environment, FRP’s non-corrosive properties offer distinct advantages over steel.

Success requires three non-negotiable elements:

- Standards compliance: Confirm NFPA 30, API, UL, SASO, and AHJ requirements before design. No single standard covers everything—integrate all applicable codes.

- Secondary containment: Always design for 110% capacity containment with impermeable base and controlled drainage. This is the final barrier against environmental liability.

- Operational discipline: Proper venting, overfill prevention, training, inspection, and maintenance prevent incidents. A well-designed tank that is neglected will fail.

Final reminder: This article provides engineering framework and best practices based on published standards. Every project is unique. Final design must always be confirmed with your AHJ (Authority Having Jurisdiction), client specifications, and certified HSE engineers. Do not rely solely on general guidance; engage qualified professionals for your specific site and application.

Call to Action

Diesel tank safety is non-negotiable. If you are designing or installing an FRP diesel storage tank in Saudi Arabia, Pioneers Fiberglass Co. Ltd. can help you navigate standards, optimize design for KSA conditions, and ensure compliance from commissioning to long-term operation.

Request a Quote for your diesel storage tank project. Provide site details (location, capacity, AHJ requirements, climate exposure) and we will size the tank, specify materials, and prepare compliance documentation.

Talk to Our Engineers if you have questions about secondary containment design, FRP material selection, heat/UV protection strategy, or how to document compliance for your AHJ.

TABLES (All Tables Summary)

Table 1: Tank Configuration Options (What to Choose)

| Configuration | Best For | Key Safety Controls | Typical Mistakes | KSA Notes |

|---|---|---|---|---|

| Single-wall aboveground horizontal tank | Generator fuel, small industrial site, temporary storage | External bund/dike wall; vent + drain; overfill gauge; spill kit | No secondary containment; poor vent routing; overfill risk | Fast to install; but bund design critical in sandy soil. Heat causes vapor buildup; ventilation essential. |

| Single-wall aboveground vertical tank | Larger capacity (fixed installation), better space efficiency | Bund wall; emergency vent; level indicator; safe fill access | Under-sized bund; fill point exposed; inadequate access for cleaning | Vertical tanks more stable in wind; but require deeper bund = higher cost in KSA rock/hard soil. |

| Double-wall (tank-in-tank) aboveground | Premium safety, environmental protection, leak detection | Interstitial space monitoring; internal tank inspection port; outer wall sensors | Complex design; difficult to inspect interstitial space; cost | Secondary containment built-in; reduces bund wall size needed. Thermal cycling may stress outer shell; thermal expansion gaps required. |

| Underground single-wall with external bund | Space-constrained sites (courtyard), ground-level access | Excavated bund/liner (HDPE or concrete); leak detection; vent head above grade | Water table interference; difficult access for inspection/maintenance; corrosion risk | KSA: high water table in some coastal areas (unfavorable); excellent UV/heat protection. Remote sites often prefer underground. |

| Day tank (small, 500–5000 L) + bulk tank (feeder) | Generator sites with automatic transfer, production facilities | Day tank has tight secondary containment + overfill alarm + gravity feed to generator; bulk tank has bund/secondary | Mixing configurations; unclear transfer procedure; overfill during bulk transfer | Common in large facilities; day tank sits near generator (heat exposure); bulk tank remote (cooler). Both require vents. |

Table 2: FRP Resin Compatibility with Diesel and KSA Conditions

| Resin Type | Diesel Compatibility | UV Resistance | Heat Performance | Cost | Recommendation |

|---|---|---|---|---|---|

| Orthophthalic polyester | Not recommended | Fair | Fair | Low | Do NOT use for diesel |

| Isophthalic polyester | Good to Excellent | Good | Good | Medium | Preferred for diesel |

| Terephthalic polyester | Excellent | Excellent | Excellent | Medium–High | Best-in-class for diesel + KSA heat |

| Vinyl ester | Excellent | Excellent | Excellent | High | Premium option; best all-round durability |

| Bisphenol-A fumarate | Good | Good | Good | High | Acceptable; less common than others above |