Introduction

FRP chemical storage tanks Saudi Arabia must be specified using real service conditions—chemical name, concentration, temperature profile, duty cycle, and the latest SDS—to select the correct resin, liner, and corrosion barrier. Plant teams across Saudi Arabia and the GCC often ask a simple question: “Is FRP safe for chemical X in my tank?”. In reality, there is no universal yes or no answer. Compatibility for any FRP chemical storage tank Saudi Arabia depends on the chemical itself, its concentration, operating temperature, duty, and how the tank is designed and lined. Outdoor yards in KSA add extra stresses: high ambient temperatures, intense UV, dust, and coastal atmospheres. In this article you will learn what “GRP chemical compatibility” really means, which inputs decide if a chemical is suitable for FRP, how resin and liner selection affect performance, and what mistakes to avoid. The goal is to help you collect the right data and get a verified engineering recommendation, not a guess.

Quick Answer

- FRP compatibility is not universal; every GRP/FRP tank must be checked for its specific service.(See source)

- Chemical + concentration + temperature decide almost everything about FRP tank chemical resistance and service life. (See source)

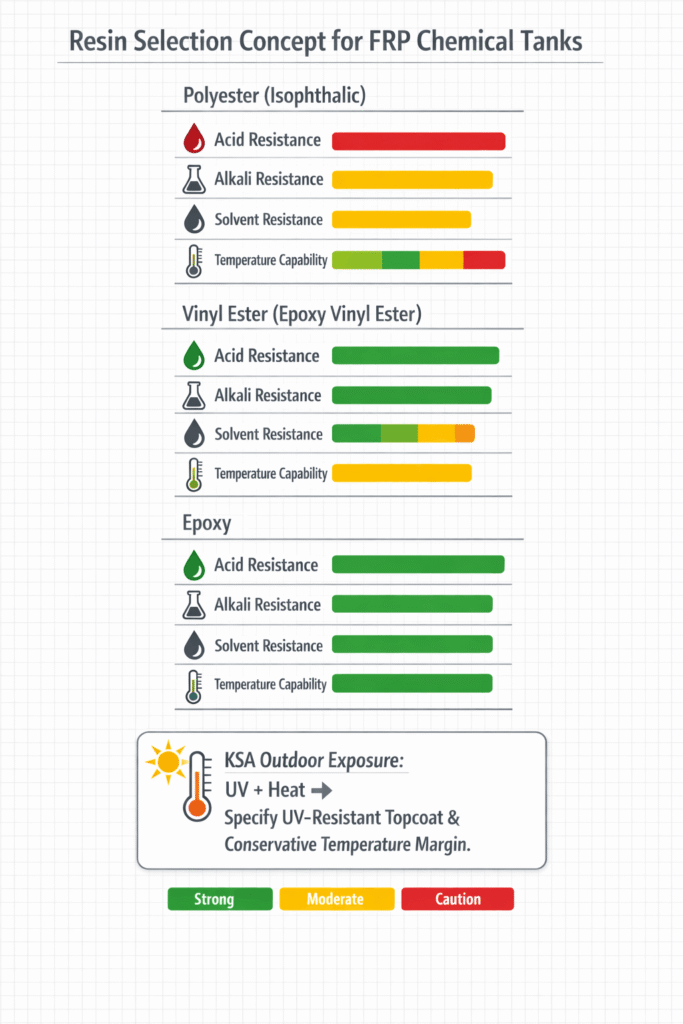

- Resin family matters (e.g., polyester vs vinyl ester vs epoxy); different chemistries show very different resistance to acids, alkalis, and solvents. (See source)

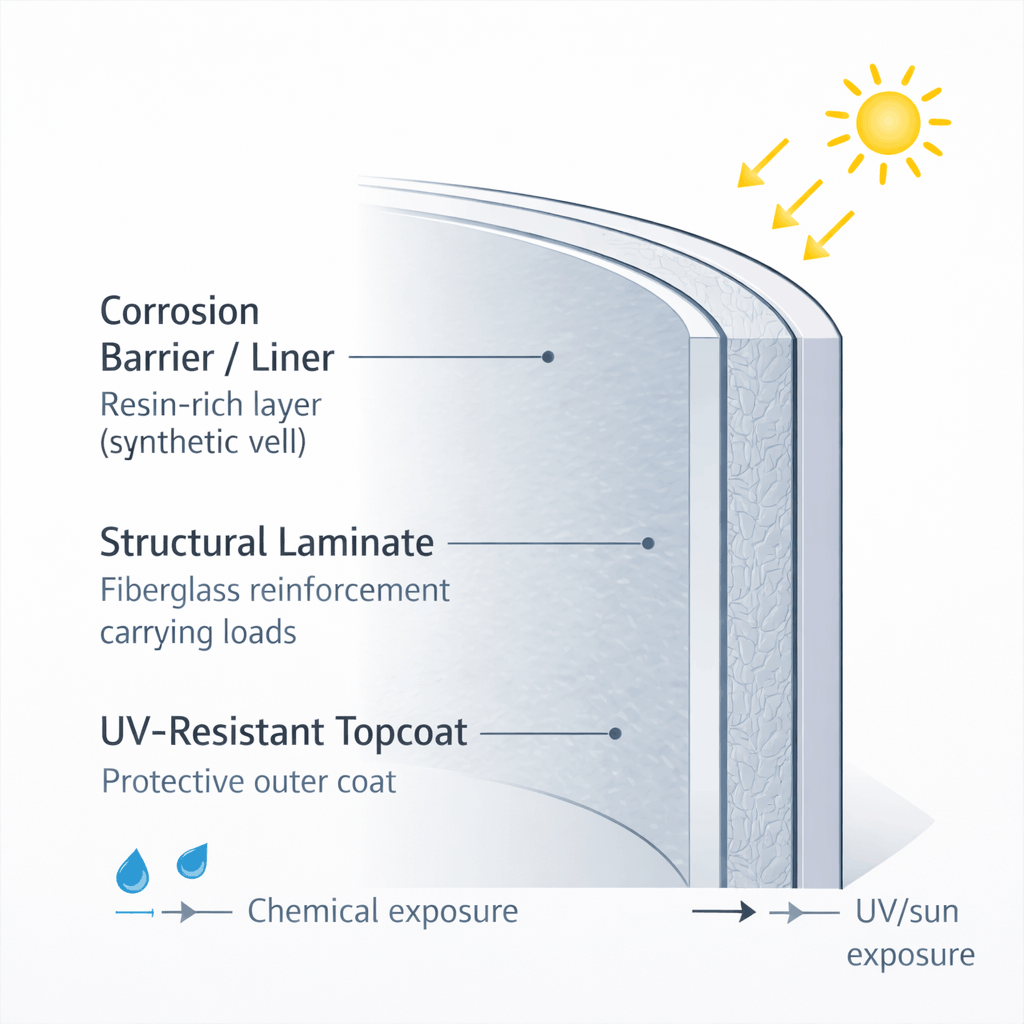

- Liner, corrosion barrier, and gelcoat selection are as critical as the structural laminate for chemical storage tank material selection. (See source)

- Oxidizers (e.g., hypochlorite, peroxide) and solvents require special caution and detailed data; no blanket “safe” claims are valid.

- You must use the SDS plus real process conditions (concentration, temperature profile, duty, impurities) to confirm compatibility.

- Outdoor KSA exposure adds UV, elevated shell temperatures, and possible salt-laden air, which must be considered in resin, topcoat, and design.

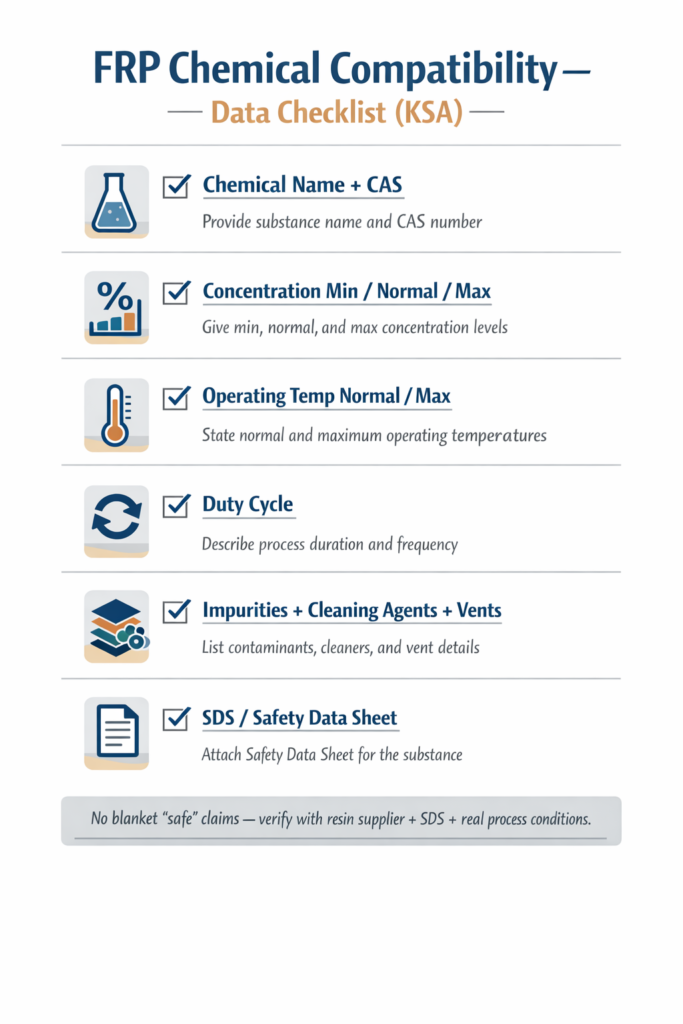

- Best next step: prepare a structured data checklist (chemical, concentration, temperature, duty, SDS) and send it to the tank supplier for a documented compatibility recommendation.

What “Chemical Compatibility” Really Means for FRP

A GRP/FRP tank is a composite system: fiberglass reinforcement provides strength, while the thermoset resin matrix and corrosion barrier liner provide chemical resistance. For a typical vinyl ester FRP tank, the corrosion barrier near the inner surface is rich in resin and veil, giving the primary resistance, while the structural layers behind it carry mechanical loads.

Chemicals can attack FRP by swelling or softening the resin, cracking due to stress plus chemical environment, or permeation through the liner over time. Elevated temperature accelerates diffusion and chemical reaction rates, so a medium that is acceptable at 25–30 °C may cause rapid degradation at 60–80 °C. Impurities, by‑products, and even cleaning chemicals can be more aggressive than the main product, changing compatibility compared with pure lab-grade chemicals. This is why GRP chemical compatibility must always be evaluated for the full real mixture, not just the name of the main chemical.

The 5 Inputs That Decide If a Chemical Is Safe in FRP

For any FRP chemical storage tank Saudi Arabia project, you should gather at least five critical inputs before asking for a material recommendation.

Chemical identity (exact name + CAS if possible)

Engineers and resin manufacturers evaluate compatibility based on specific chemical species, not trade names or generic descriptions. Provide the exact chemical name, common synonyms, and CAS number if available

Concentration range (min/normal/max)

Chemical resistance charts clearly show that allowable temperature ranges for FRP change with concentration, especially for acids and caustic. You should provide minimum, normal, and maximum expected concentrations over the life of the tank, including upset conditions.

Operating temperature (normal/max)

Vinyl ester and other resins have recommended upper service temperatures beyond which properties drop and chemical attack increases. Provide normal operating temperature, possible peaks during filling, reactions, or cleaning, and any thermal cycling.

Duty cycle (static storage vs recirculation, filling frequency)

Continuous recirculation, frequent agitation, or rapid filling/emptying all add mechanical and thermal stresses that interact with the chemical environment. Clarify whether the tank is for static storage, buffer/service duty, or part of an agitated process, and how often it will be cycled.

Mixtures/impurities + cleaning agents + vent emissions

Mixtures such as acids with oxidizers, or caustic with organic contaminants, can behave very differently to each component alone. You should list likely impurities, CIP or manual cleaning chemicals, and any vapours/condensate that may contact the roof, nozzles, and vent system.

Common Chemical Families and FRP (Practical Screening Guide)

Use the following as a screening guide only. Final acceptance for a given FRP chemical storage tank Saudi Arabia must rely on specific resin manufacturer data plus the SDS and process conditions

Acids (mineral vs organic)

Vinyl ester resins are widely used in equipment for many mineral and organic acids because they generally offer high acid resistance compared with standard polyesters. For example, a representative vinyl ester chemical resistance chart reports that sulfuric acid in the 30–50% range is “resistant” up to around 100–120 °C, while higher concentrations may require lower temperature limits or special grades.

Organic acids such as acetic and citric are often manageable with appropriate vinyl ester systems, within charted concentration and temperature limits. Hydrochloric and phosphoric acids are commonly handled in FRP, again subject to the resin manufacturer’s specified boundaries. Nitric and mixed oxidizing acids require extra caution; only certain high‑performance vinyl ester or dual‑laminate systems are acceptable, and often only at limited concentration and temperature.

Alkalis (caustic / ammonia solutions)

Vinyl ester and some isophthalic polyester resins can provide good resistance to many sodium hydroxide solutions, with charts listing resistance up to 50% NaOH at moderate temperatures for suitable vinyl ester grades. However, alkaline environments can affect resin networks over time, especially at elevated temperatures, so confirming both temperature and exposure duration is critical. Ammonia and amine-rich solutions may require careful resin selection and sometimes favour specific epoxy vinyl ester or epoxy systems depending on concentration and temperature.

Salts / brines

Most common inorganic salt solutions and brines (e.g., sodium chloride, many nitrate or sulfate salts) are generally favourable services for GRP tanks, especially at ambient to moderate temperatures, and are widely cited as suitable applications for vinyl ester FRP. Nevertheless, some salt solutions with high pH, oxidizing behaviour, or elevated temperature (for example, hot sodium hypochlorite brine) can be challenging and must be checked individually.

Hydrocarbons / fuels

Hydrocarbon and fuel service is highly dependent on resin type, permeation behaviour, and temperature. Some vinyl ester and epoxy systems can perform well with certain hydrocarbons and fuels within specific limits, while others may suffer from swelling or softening, especially with aromatic-rich or solvent‑like components. For fuel and hydrocarbon duties, permeation, fire safety, and local standards must be evaluated along with chemical compatibility charts.

Oxidizers (high caution)

Strong oxidizers such as sodium hypochlorite, chlorine dioxide, and concentrated hydrogen peroxide can significantly stress FRP liners. Representative vinyl ester charts may rate sodium hypochlorite as “resistant” only at specific concentrations and temperatures, for example 10% NaOCl with a maximum service temperature in the range of approximately 40 °C–65 °C depending on resin grade. In hot KSA outdoor conditions, shell temperatures can approach or exceed these limits in summer, so a conservative approach and detailed design review are essential.

Solvents (high caution)

Many organic solvents can attack FRP by penetrating and plasticizing the resin matrix, or by extracting components. Compatibility charts show that common solvents such as acetone, styrene, or some esters and ketones are often “not recommended” for standard FRP systems, while limited resistance may exist for specific alcohols or aromatics at lower temperatures. For any solvent-rich mixture, detailed consultation with the resin supplier and a review of the full formulation are mandatory.

Hypochlorite / chlorinated solutions

Sodium hypochlorite, chlorinated water, and similar oxidizing chlorine solutions can be challenging services for FRP, depending strongly on concentration, pH, and temperature. Vinyl ester charts may indicate acceptable performance for low to moderate hypochlorite concentrations at controlled temperatures, but attack accelerates when temperature rises or when solutions are acidic. In KSA, hot climate and outdoor installation can raise tank wall temperatures, so design for hypochlorite usually combines conservative temperature limits, careful resin selection, ventilation, and strict operating controls.

In all cases above, if you do not have a compatibility entry for your exact chemical, concentration, and temperature from a credible chart or resin selection guide, treat it as “unknown” and confirm with compatibility data + SDS + resin selection.

Resin & Liner Selection (Why “FRP” Is Not One Material)

The term FRP chemical storage tank Saudi Arabia covers a wide family of materials, not a single specification. Unsaturated polyesters, vinyl esters, and epoxies are three common resin families, and each has different resistance to acids, alkalis, and solvents. Vinyl ester resins, particularly epoxy vinyl ester grades, are widely documented as offering excellent general chemical resistance and higher temperature capability than standard polyesters in many corrosive environments

The corrosion barrier or liner is a resin‑rich layer, often including chemical‑resistant veil, designed specifically to resist the stored medium, while the structural laminate behind it focuses on strength. For demanding services, specialized “vinyl ester FRP tank” designs or dual‑laminate systems (FRP structural with a thermoplastic liner) are used following resin selection guides from major suppliers.

For outdoor tanks in KSA, UV‑resistant topcoats and pigments help limit surface degradation from sunlight, while formulation choices and post‑cure practices improve long‑term performance at elevated shell temperatures. Fire‑retardant additives or glass flake fillers can also be used where required by standards or risk assessments, though these must be balanced against mechanical property changes.

High-Risk Cases Where Engineers Must Double-Check

Certain services should always trigger a deeper compatibility and design review before confirming an FRP chemical storage tank Saudi Arabia:

- Hot, concentrated acids or caustic (for example, high‑strength sulfuric or sodium hydroxide at elevated temperature).

- Strong oxidizers (sodium hypochlorite, chlorine dioxide, peroxide solutions, mixed oxidizing acids).

- Solvent‑rich mixtures or fuels with significant aromatic or polar solvent content.

- Chemical mixtures with unknown impurities, variable composition, or potential for unexpected by‑products.

- Elevated temperature combined with frequent filling and emptying, which increases mechanical and thermal cycling on the liner.

- Vacuum or pressure cycling that may stress the laminate and affect liner adhesion or crack initiation.

- Incorrect gasket or seal material selection at nozzles and flanges, leading to local leakage and attack, even if the tank shell is compatible.

Head-to-Head Table: FRP vs Steel vs HDPE (Chemical Storage)

Selecting between FRP/GRP, steel, and HDPE/PP for chemical storage tank material selection requires balancing corrosion resistance, temperature, UV exposure, and site conditions in Saudi Arabia. Fiberglass tanks can offer strong corrosion resistance in many acid and brine services, while coated steel or stainless may be preferable for very high temperatures or certain solvents, and HDPE/PP can be cost‑effective for mild chemicals at moderate temperatures.

Design Best Practices for Chemical FRP Tanks in KSA

Good design practices are essential to translate theoretical FRP tank chemical resistance into safe, long service life in Saudi conditions. Secondary containment (bunds or dykes) sized per site standards and chemical hazard helps manage leaks and overflows; drainage should direct spills to a controlled area, not to stormwater.

Venting and fume control must follow the chemical’s vapour pressure and reaction risk, with vents sized and positioned to avoid over‑pressure or vacuum and to manage corrosive condensate attack on roofs and vent lines. Nozzles, manways, and pipe supports should be reinforced so that external loads from piping, wind, and thermal movements do not overstress the shell. Foundations should provide uniform support, suitable for local soil and temperature, and allow safe access for inspection around the tank and bund. Clear labeling, hazard signage, and up‑to‑date SDS at the tank location are crucial for safe operation and emergency response.

Inspection & Maintenance (What to Check and How Often)

FRP tanks require a structured but practical inspection regime aligned with the chemical hazard and KSA outdoor conditions

- Daily/weekly: Operators should visually check for leaks, drips, wet spots, discoloration, unusual odours, and any obvious damage to shell, nozzles, and bund.

- Monthly: Inspect flanges, gaskets, supports, drains, and containment for signs of seepage, corrosion of metal components, settlement, and standing liquid.

- Quarterly: Review fittings, vents, level instruments, ladders, and platforms, and clean the area around the tank to remove debris, sand accumulation, and combustible materials.

- Annual: Conduct a more detailed integrity inspection per site procedures, which may include internal inspection during shutdown, NDT on critical areas, and review of chemical compatibility if the service has changed.

All inspections should be recorded with date, findings, and actions taken; this documentation is essential for demonstrating control and for trending any degradation.

Common Mistakes to Avoid

- Asking “is FRP OK?” without giving concentration, temperature, and duty details.

- Assuming one FRP tank suits all chemicals and changing service without re‑checking compatibility.

- Ignoring KSA heat and outdoor UV exposure when selecting resins, colours, and topcoats.

- Using the wrong gasket/seal materials at nozzles and manways, leading to early leakage.

- Mixing incompatible chemicals in the same tank or bund, causing reactions and unexpected corrosion.

- Poor bund drainage control, allowing standing aggressive liquids that attack external surfaces and foundations.

- Providing no safe access (platforms, lighting) for inspection, which leads to inspections being missed.

- Operating with no labeling, signage, or SDS available at the tank.

- Using aggressive cleaning chemicals or high‑pressure methods without checking compatibility with the liner.

- Ignoring vent emissions and condensate attack on roofs and vent lines in oxidizing or acidic services.

- Keeping no maintenance/inspection logs, making it impossible to track trends or justify service life.

- Copying a design from a different chemical service or climate without proper engineering review.

FAQs

Q1: Which chemicals are safe to store in FRP tanks?

A: There is no single “safe list”; FRP compatibility depends on chemical, concentration, temperature, resin type, and liner design, and must be checked against a credible chemical resistance chart and resin selection guide for your exact conditions. For many mineral acids, salts, and brines, properly selected vinyl ester FRP performs well within specified limits, but you should always confirm with compatibility data + SDS + resin selection.

Q2: Is FRP good for acid storage?

A: Vinyl ester FRP is widely used in storage and process equipment for sulfuric, phosphoric, hydrochloric, and various organic acids, and case studies report long service life when properly designed. However, performance depends on acid type, concentration, and temperature; for example, charts for sulfuric acid show changing allowable temperatures at different strengths, and oxidizing acids often require more conservative limits or special grades. For any acid storage tank FRP in Saudi Arabia, request a recommendation based on your full process data.

Q3: Is FRP compatible with caustic soda?

A: Many vinyl ester and selected polyester systems show good resistance to sodium hydroxide solutions up to significant concentrations at moderate temperatures according to published resistance tables. Nevertheless, long‑term alkaline exposure at higher temperatures can affect resin networks, so the service temperature, concentration, and mechanical loading must be reviewed before finalising an alkali storage tank GRP design.

Q4: Can FRP store chlorine or hypochlorite?

A: Chlorine‑containing oxidizing media such as sodium hypochlorite and chlorinated water are recognised as demanding services and require careful selection of resin, liner thickness, and operating limits. Resistance charts may list certain vinyl ester systems as suitable for specific hypochlorite concentrations and temperatures, but in hot KSA conditions, conservative temperature control and regular inspection are essential, and borderline cases may require alternative materials or dual‑laminate designs

Q5: What resin should I use for a chemical tank?

A: For many corrosive services, vinyl ester resins are recommended due to their generally higher chemical and temperature resistance compared to standard unsaturated polyesters. Epoxy vinyl ester grades and specialty formulations give additional resistance for high‑temperature or highly aggressive environments, while some epoxies or dual‑laminate constructions may be used for specific solvents or special media. The correct choice must follow the resin manufacturer’s selection guide for your chemical, concentration, and temperature envelope.

Q6: How does temperature affect FRP chemical resistance?

A: Temperature strongly influences diffusion, reaction rates, and mechanical properties of resin matrices; higher temperature usually reduces the safety margin and accelerates degradation. Vinyl ester data typically specify maximum recommended service temperatures (often around 100–120 °C for many grades in suitable media), and compatibility ratings for a given chemical are tied to those limits. In Saudi Arabia, high ambient and solar heating can push tank wall temperatures above the bulk liquid temperature, so this must be considered in design.

Q7: FRP vs HDPE for chemical storage: which is better?

A: HDPE and PP are well suited to many mild acids and bases at moderate temperatures, but have lower allowable service temperatures and can deform under load compared with FRP. FRP (especially vinyl‑ester‑based composites) offers higher stiffness and temperature capability and often better long‑term resistance in strong acids or hot brines, making it a strong candidate for many FRP chemical storage tank Saudi Arabia applications. The better choice depends on your specific chemical, temperature, mechanical loads, and life‑cycle cost targets.

Q8: What information do you need to confirm compatibility?

A: To issue a responsible recommendation, a supplier needs at least chemical name and CAS, concentration range, operating and maximum temperature, duty (static or agitated, filling pattern), impurities and cleaning agents, and the SDS. With this, they can check resin selection guides and chemical resistance charts, and then propose a suitable FRP lining for chemicals, including resin type, corrosion barrier design, and any special construction details.

Conclusion

For chemical storage tank material selection in Saudi Arabia and the GCC, GRP/FRP offers strong advantages when the resin, liner, and design are matched carefully to the actual chemical service and local climate. There is no one‑size‑fits‑all answer; the safety and service life of each FRP chemical storage tank Saudi Arabia depend on chemical, concentration, temperature, duty, and outdoor exposure.

If you are planning or upgrading a tank yard, the next step is to share your data and get an engineering‑based recommendation, not a generic “OK”. Request a Quote or Talk to our engineers and include: chemical name, concentration range, operating/max temperature, duty description, and the latest SDS. This allows a tailored FRP tank chemical resistance assessment and a design that fits real KSA conditions and your site’s safety standards.

Tables (all tables together)

Table 1 – Inputs for FRP Chemical Compatibility

| Input | Why it matters | What to provide to supplier |

|---|---|---|

| Chemical identity | Compatibility is evaluated per specific chemical, not generic names; different chemicals with similar names can behave very differently in FRP. | Exact chemical name, common synonyms, CAS number, phase (liquid/gas), and key physical data if available. |

| Concentration range | Resistance charts show different allowable temperatures and ratings at different strengths, especially for acids and caustics. | Minimum, normal, and maximum concentration in %, including possible upset or cleaning phases. |

| Operating temperature | Temperature accelerates permeation and reaction and many resin data sheets specify maximum service temperatures by chemical. | Normal operating temperature, maximum short‑term peaks, and any expected thermal cycling profile. |

| Duty cycle | Agitation, recirculation, and frequent filling increase mechanical stress and may shorten life even if the medium is compatible. | Whether service is static storage, buffer, or process; filling frequency, mixing, and pump‑out patterns over a typical day/week. |

| Mixtures/impurities & cleaning/vents | Impurities, cleaning agents, and vent condensate may be more aggressive than the main product and attack roofs, nozzles, and external surfaces. | List of typical impurities, by‑products, cleaning chemicals, and expected vapours/condensate composition and temperature. |

Table 2 – FRP vs Steel vs HDPE/PP for Chemical Storage in KSA

| Feature | FRP/GRP | Steel (coated/SS) | HDPE/PP | Notes for KSA |

|---|---|---|---|---|

| Corrosion resistance | Excellent in many acids, salts, and brines when proper vinyl ester or epoxy systems are selected; no electrochemical rusting. | Carbon steel needs internal linings and external coatings; stainless improves resistance but can pit in chlorides and some acids. | Good for many dilute acids and bases; limited for strong oxidizers, some solvents, and high‑temperature service. | Coastal and industrial atmospheres in KSA favour non‑metallic or well‑protected materials; verify for specific chemicals. |

| Temperature tolerance (general) | Typical vinyl ester FRP operates up to around 100–120 °C in suitable media; special grades can go higher. | Unlined carbon steel tolerates high temperatures but may corrode; alloys and linings used for hot, aggressive service. | HDPE is usually limited to roughly 60–70 °C and PP somewhat higher, depending on grade and load. | High ambient and solar heating in KSA can raise tank wall temperatures; FRP and steel handle this better than HDPE in many cases. |

| UV exposure outdoor | UV‑stabilised and top‑coated FRP performs well outdoors with appropriate maintenance. | Coatings on steel degrade under UV and need periodic maintenance; stainless is more stable but costlier. | Unprotected HDPE/PP can chalk, embrittle, and crack over long‑term UV exposure. | KSA sun levels make UV protection and inspection critical for all materials. |

| Mechanical impact risk | Stiff and strong; local impact can cause cracks that may be repaired with composite techniques. | High toughness and ductility for many steels; impacts may dent rather than crack but can damage linings. | More flexible; impacts may deform tanks and create stress cracking, especially at fittings. | Wind‑borne debris and mobile equipment in yards require physical protection and layout planning. |

| Maintenance & repair approach | Repairs performed with compatible resin/laminate systems; surface preparation and cure control are essential. | Steel requires coating repair, corrosion monitoring, and sometimes weld repairs; stainless may need passivation. | HDPE/PP repairs often involve plastic welding or tank replacement depending on damage. | In remote KSA sites, availability of skilled FRP, welding, or coating contractors should influence selection. |

| Total cost of ownership (non‑numeric) | Often favourable in corrosive services due to low corrosion allowance needs and long life when correctly specified. | Initial cost can be moderate to high depending on grade; lifecycle cost increases with corrosion management. | Low capital cost, but life may be shorter in hot or UV‑intense environments, driving earlier replacement. | Evaluate CAPEX plus expected lifetime, maintenance frequency, and downtime risk for KSA/GCC sites. |

| Best use cases | Many acids, brines, and corrosive industrial effluents; customized shapes and sizes; FRP chemical storage tank Saudi Arabia yards with high corrosion demand. | Very high‑temperature or pressure service, certain solvents or hydrocarbons, and where metallic piping integration is dominant. | Mild chemicals at low to moderate temperatures, small day tanks, and services where low initial cost is critical. | In KSA, a mix of FRP, lined steel, and HDPE/PP is often used across the same plant depending on chemical service. |