Introduction

Saudi Arabia and the wider GCC have some of the harshest environments for buried sewer structures: sulfate-rich soils in parts of the Kingdom, saline groundwater, coastal chlorides, high temperatures, UV and aggressive sewer gases. Many traditional concrete manholes show corrosion, leakage and joint problems under these conditions, especially when detailing and protection are limited. This is why composite manhole (GRP manhole) systems in Saudi Arabia (KSA) appear more often in municipal and industrial projects. In this article, we explain what actually damages concrete manholes, how GRP behaves differently, lifecycle and installation implications in KSA, and where concrete is still appropriate. You will also see what data engineers should send in an RFQ to select the right manhole type for each site.

Quick Answer

- Concrete can suffer chemical attack in aggressive soils and sewers, causing loss of cover, cracking and leakage, especially under sulfate, chloride and H₂S exposure (varies by site conditions and specs).

- GRP provides corrosion resistance to many soil and sewage environments (resin- and design-dependent) and can offer tight, gasketed joints in a composite manhole system.

- Lighter weight improves installation speed, reduces lifting risk and supports lightweight manhole installation on constrained or remote KSA sites (compared to heavy concrete sections).

- Watertight joints and seals reduce infiltration/exfiltration in high groundwater areas when correctly designed and installed, lowering the risk of fines migration and sinkholes.

- Typical experience shows less rehabilitation and fewer leak complaints for corrosion resistant manhole systems in aggressive sewers, but performance varies by site chemistry, design and QA/QC.

- KSA heat and UV require proper GRP covers, pigments or coatings, and correct installation to manage thermal movements and protect exposed surfaces.

- Engineers should choose between GRP manhole Saudi Arabia options and concrete based on soil/water chemistry, H₂S risk, traffic load, depth and project specifications.

- RFQs should include diameter, depth, soil and groundwater reports, sewer loading, traffic class, connection types and any local/AHJ standards to allow correct selection and detailing.

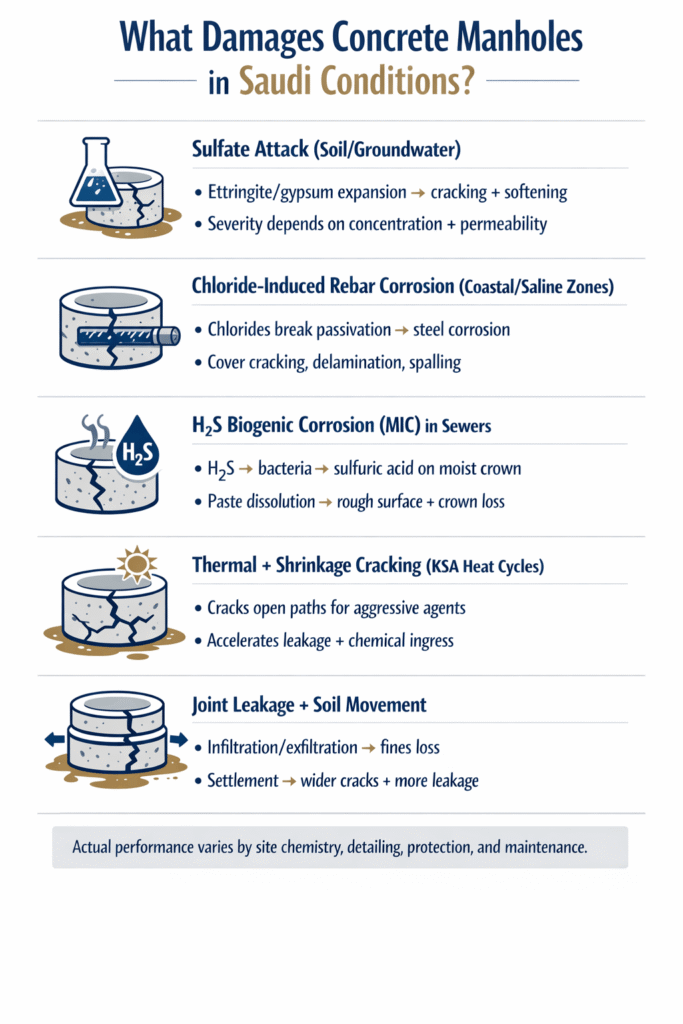

What Damages Concrete Manholes in Saudi Conditions?

Concrete manholes in Saudi Arabia face a combination of chemical and physical deterioration: sulfate-bearing soils or groundwater, coastal chlorides that attack reinforcement, and microbiologically induced sulfuric acid corrosion from sewer H₂S. Thermal cycling, shrinkage and joint defects then allow infiltration and exfiltration, accelerating chemical attack and undermining backfill support. Service life for concrete wastewater structures can be 50–60 years when designed and protected in line with environmental engineering codes, but actual performance in KSA conditions varies widely with exposure class, detailing and maintenance.

Key mechanisms in Saudi and GCC environments include:

- Sulfate attack: Sulfate ions from soil or groundwater react with cement hydration products, forming expansive ettringite and gypsum, which can crack and soften concrete over time.

- Chloride-induced reinforcement corrosion: In coastal or saline-groundwater zones, chlorides penetrate concrete, break down the steel passivation layer and cause rebar corrosion and cover cracking.

- H₂S biogenic corrosion: In gravity sewers, hydrogen sulfide gas is oxidized by bacteria on moist concrete surfaces to sulfuric acid, which dissolves calcium hydroxide and calcium silicate hydrates.

- Thermal and shrinkage cracking: High daily temperature swings and restrained shrinkage can open cracks, allowing faster ingress of sulfates, chlorides and acidic liquids.

- Joint leakage and soil movement: Poorly sealed joints allow infiltration/exfiltration, loss of fines and differential settlement, increasing crack widths and leak paths.

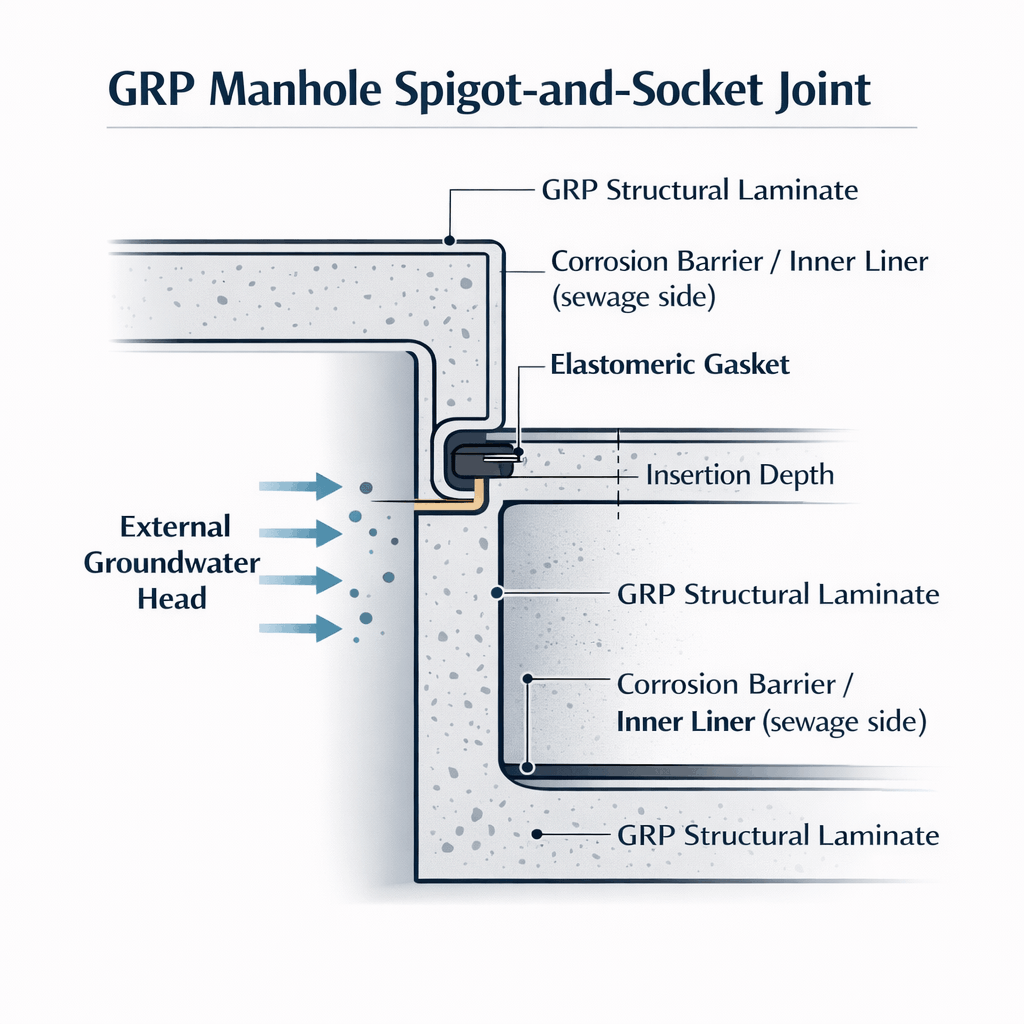

What Makes GRP Different? (Material + System)

A GRP manhole Saudi Arabia design uses glass fiber reinforcement and a thermoset resin matrix to create a composite shell that is largely inert to many common soil and sewage chemistries encountered in the region, provided the resin system is correctly specified. Unlike cementitious materials, GRP does not contain free calcium hydroxide that dissolves under sulfuric acid attack, and it does not rust in chloride-bearing groundwater. This makes it suitable for corrosion resistant manhole applications where sewer manhole H2S corrosion has previously damaged concrete, though compatibility must still be checked against any industrial effluents or unusual chemicals.

Typical GRP manhole construction includes:

- Structural laminate: Glass fibers provide strength and stiffness, while resin transfers loads and protects against moisture and many chemicals.

- Corrosion barrier / inner liner: A resin-rich inner layer (often with veil reinforcement) improves resistance to sewage and H₂S-induced acidic condensate.

- Smooth bore: A smooth internal surface improves hydraulic performance and makes cleaning and CCTV inspection easier compared with rough concrete.

- Watertight joints: Factory-formed spigots with elastomeric gaskets or mechanical couplings can provide tight joints that reduce infiltration/exfiltration when installed correctly.

- Non-conductive, corrosion-resistant hardware: In coastal KSA sites, stainless steel, coated, or composite accessories are often chosen to avoid galvanic corrosion with saline spray and groundwater.

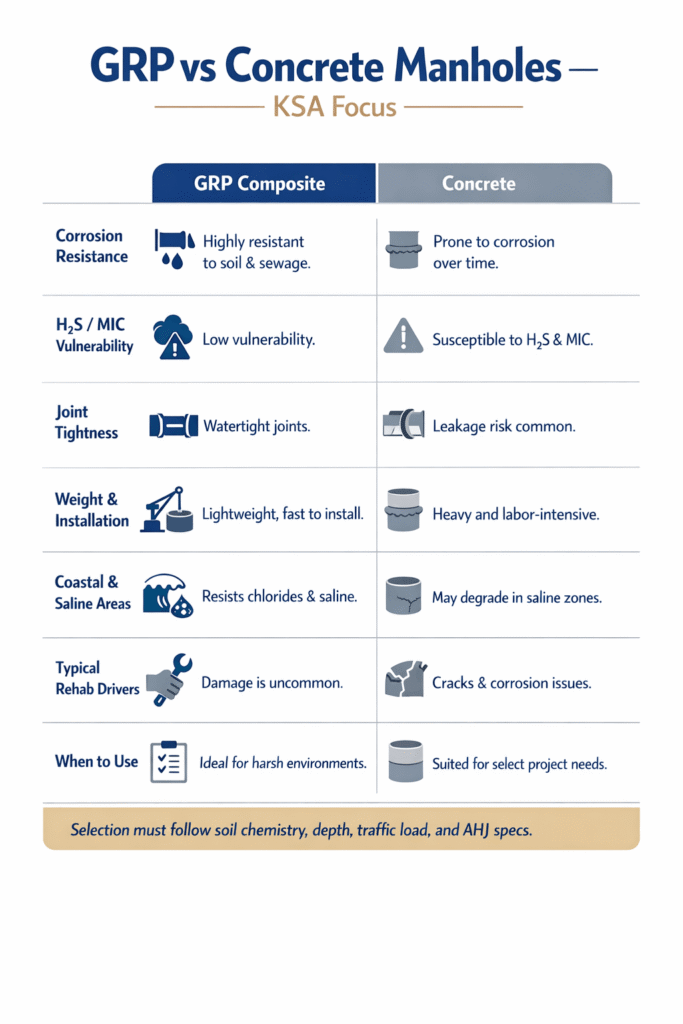

GRP vs Concrete Manholes

From a systems perspective, a GRP manhole Saudi Arabia installation behaves differently from a reinforced concrete manhole: lower weight, different bedding needs, and different failure modes. Concrete manhole corrosion issues are dominated by chemical reactions and steel corrosion, while GRP issues are more related to handling damage, UV exposure of covers and joint detailing. For municipalities, the choice often comes down to expected service life under local soil chemistry, leakage tolerance, construction logistics and long-term O&M budgets (all of which vary by project and specification).

(Comparison table is provided in the “Tables” section.)

Saudi Soil & Groundwater Factors (What Engineers Check)

For both concrete and GRP, correct selection of a manhole system in KSA starts with understanding the subsurface environment: soil chemistry, groundwater levels and any industrial discharges into the network. Sulfate attack Saudi soil risk is particularly relevant in parts of the Eastern Province and other sulfate-bearing formations, while coastal chloride and high groundwater salinity are critical near the Arabian Gulf and Red Sea. Sewer manhole H2S corrosion risk is higher in long, low-velocity gravity sewers with warm sewage, which are common in the region’s climate and can severely damage unprotected concrete over time.

Engineers typically evaluate:

- Soil sulfate and chloride content (water-soluble and total).

- Groundwater level, salinity and seasonal fluctuation.

- Presence of industrial or brine effluents (e.g., from petrochemical, food or desalination plants).

- Sewer gas/H₂S generation potential in gravity lines and wet wells.

- Coastal vs inland exposure, including airborne salt.

A GRP manhole Saudi Arabia specification should call for soil and groundwater data so that the resin system, wall thickness, joint type and any external coatings or protective measures can be selected to match the local environment. For concrete, these same results drive choice of cement type, w/c ratio, cover, coatings and special MIC-resistant materials.

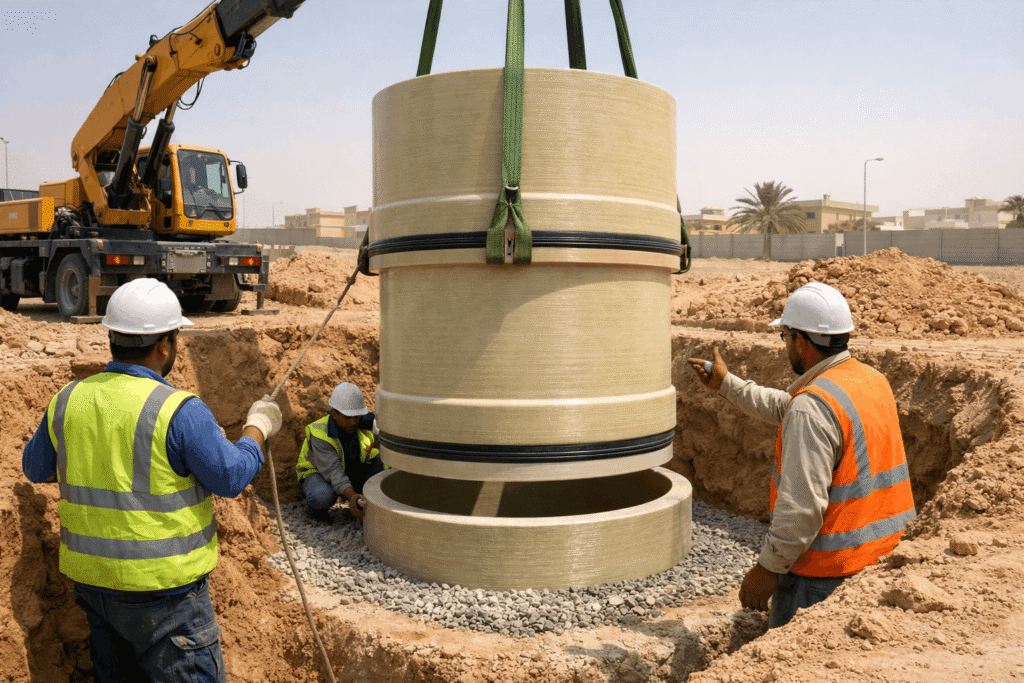

Installation Advantages in KSA Projects

One of the main advantages of a composite manhole system is its low weight compared with reinforced concrete. This supports lightweight manhole installation, faster crane cycles and, in some cases, the use of smaller lifting equipment or even manual positioning for certain cover and riser elements. In congested residential streets or remote desert projects, this can reduce traffic disruption, logistics costs and safety risks during handling and installation, though ground conditions and safety plans still govern equipment selection.

Other practical benefits for KSA projects include:

- Reduced crane dependency in tight urban areas or where large cranes are difficult to mobilize.

- Easier transport to remote or soft-sand sites where heavy concrete sections would require more substantial haulage equipment and road preparation.

- Factory-integrated bases and step irons (if specified) can reduce on-site construction time and help with consistent alignment.

- Watertight joints, when installed per manufacturer instructions, can result in fewer infiltration complaints in high groundwater zones.

- Cleaner site work around existing utilities, since smaller excavation and lighter components can often be used, provided proper bedding and compaction are maintained.

When Concrete Can Still Be the Right Choice

Concrete manholes remain appropriate for many applications in Saudi Arabia when properly designed, detailed and protected for the local exposure class. Environmental concrete standards targeting liquid-tightness, crack control and durability (for example, ACI 350-type provisions) can deliver long service lives when combined with appropriate coatings or liners. In some projects, the specification, approvals process or contractor experience strongly favors conventional concrete.

Concrete may be preferable where:

- Very large diameter or very deep structures are required and cast-in-place concrete shafts are already standard.

- The project has proven concrete details, MIC-resistant linings and QA/QC procedures that asset owners trust.

- The supply chain or authority having jurisdiction mandates concrete for certain standard details or for compatibility with adjacent structures.

- External protective liners or coatings will be installed regardless of base material, reducing the incremental benefit of a GRP shell.

In every case, the selection between GRP manhole Saudi Arabia solutions and concrete should follow project specifications, life-cycle cost review and AHJ requirements, not material preference alone.

Best Practices to Maximize GRP Manhole Performance

To get the expected durability benefits from a corrosion resistant manhole, design and installation must match Saudi conditions and project requirements. Many performance issues in composites relate to handling, bedding, joints and accessories rather than the GRP laminate itself. A structured checklist helps designers, contractors and inspectors align on responsibilities and acceptance criteria.

Step-by-step checklist:

- Confirm diameter, depth and traffic load area (road class, wheel loads, cover class).

- Verify soil/groundwater chemistry, including sulfates, chlorides and groundwater level (especially in coastal or saline aquifer areas).

- Select a suitable joint system and gasket material rated for the expected groundwater head and soil movements, and compatible with connecting pipes.

- Ensure correct bedding and backfill materials (graded, compacted, non-aggressive) to distribute loads evenly and prevent point loads on the GRP shell.

- Check verticality, alignment and cover seating to avoid rocking, noise and local stress concentrations at the frame.

- Verify watertightness with appropriate tests (e.g., hydrostatic exfiltration or vacuum tests) as specified for the project, recognizing that test limits should follow applicable standards and AHJ requirements.

- Document installation, inspection, test results and any repairs for future asset management and warranty conditions.

Inspector checks (examples):

- Review soil/groundwater report and confirm that specified GRP system matches exposure class.

- Confirm lifting points and procedures were followed to avoid laminate damage.

- Check bedding thickness, gradation and compaction records.

- Inspect joints and gaskets for damage, cleanliness and correct lubrication/assembly.

- Witness watertightness tests and record test pressures, durations and outcomes.

Common Mistakes to Avoid (12 bullets)

- Ignoring soil/groundwater chemistry data when selecting between GRP and concrete, or when choosing resin systems and protective measures (performance then becomes highly site-dependent).

- Poor bedding or compaction causing settlement and local overstress of the manhole wall or frame.

- Misalignment between manhole, cover frame and connecting pipes, creating joint stress and potential leakage paths.

- Selecting the wrong cover load class in traffic areas, leading to premature cracking or frame damage under wheel loads.

- Not sealing pipe connections and penetrations properly, allowing infiltration/exfiltration even when manhole section joints are watertight.

- Using incompatible or aggressive backfill material (e.g., sharp rock, contaminated fill) that can damage GRP or undermine concrete durability.

- Failing to protect manholes and covers from construction damage such as impact from equipment or dropping heavy items on frames.

- No QA/QC documentation of installation procedures, compaction, joint assembly and testing.

- Assuming “GRP = maintenance free”; all buried sewer assets still require inspection, cleaning and condition assessment over time.

- Poor cover seating leading to noise, rocking, water ponding or uneven load transfer into the neck of the manhole.

- Skipping groundwater infiltration checks in high water table areas, which can mask early leakage until fines loss or settlement occurs.

- Not planning access for cleaning and future manhole rehabilitation KSA works such as lining or internal repairs.

Tables (all tables together)

Table 1 – Damage mechanisms for concrete manholes in KSA

| Damage mechanism | Where it happens | What it causes | Visible signs |

|---|---|---|---|

| Sulfate attack | Sulfate-bearing soils and groundwater around buried concrete walls and bases. | Expansion of ettringite/gypsum, softening and cracking of concrete (rate varies by concentration and permeability). | Surface softening, map cracking, loss of arrises, spalling near wetted zones. |

| Chloride-induced steel corrosion | Coastal areas, saline groundwater, chloride-contaminated soils and backfill. | Corrosion of reinforcement, cracking and delamination of cover concrete (initiation time varies with cover, w/c and chlorides). | Rust staining, longitudinal cracks over bars, delaminated cover, spalling. |

| H₂S biogenic corrosion | Sewer gas space above flow line in gravity manholes and wet wells. | Sulfuric acid production on moist surfaces, loss of cement paste, reduced thickness and strength. | Exposed aggregate, rough soft surface, severe crown loss, acid smell. |

| Thermal/shrinkage cracking | Throughout wall and cone sections, especially at restraints and changes in thickness. | Crack networks that increase permeability, allow faster ingress of aggressive agents and leakage. | Fine to wide cracks, sometimes with differential discoloration or deposits. |

| Joint leakage & soil movement | Section joints, pipe connections, benching transitions. | Infiltration/exfiltration, fines migration, settlement, possible pavement or ground failure. | Active drips, stained joints, voids at exterior, depressions at surface. |

Table 2 – Head-to-head: GRP vs concrete manholes (KSA focus)

| Feature | GRP manholes | Concrete manholes | Notes for KSA |

|---|---|---|---|

| Corrosion resistance (soil + sewage) | Resistant to many sulfates, chlorides and sewer acids when appropriate resin and barrier are used; no steel to rust (performance varies by chemistry and resin). | Cement matrix and steel can deteriorate under sulfates, chlorides and MIC unless special cements, coatings or liners are used. | GRP manhole Saudi Arabia projects often target aggressive soils or high H₂S areas; concrete still viable with correct protection. |

| Joint tightness / leakage risk | Factory-formed spigot and gasket joints can achieve high watertightness when installed correctly. | Precast concrete joints can be watertight, but mortar degradation, movement and gasket aging often increase leakage over time. | High groundwater and saline aquifers in KSA make joint design, testing and QA critical for both materials. |

| Weight & installation speed | Much lighter; enables lightweight manhole installation, faster handling and smaller cranes, especially in constrained or remote sites. | Heavy; often requires larger cranes, more lifting planning and longer installation times. | Weight advantage is significant in soft desert soils and congested urban streets. |

| Transport/logistics to remote sites | Easier to transport multiple units per truck; suitable for long-distance deliveries to remote GCC projects. | Fewer units per truck due to weight; higher fuel and road preparation requirements. | Logistics savings depend on distance, road conditions and available equipment. |

| Rehabilitation frequency (typical) | Typically lower frequency of corrosion-driven rehabilitation when correctly specified for chemistry; damage often related to joints or impact (varies by maintenance). | Often requires coatings, liners or structural repair in aggressive sewers after years of MIC and chemical attack. | Many KSA utilities pursue manhole rehabilitation KSA programs mainly for deteriorated concrete structures. |

| Surface finish & hydraulic performance | Smooth internal surface, low roughness; can reduce sediment accumulation and ease cleaning. | Rougher surface; may increase headloss and sediment deposition, particularly once corrosion or scaling occurs. | Smooth bore helps with CCTV inspection and jetting in long gravity sewers. |

| Long-term lifecycle cost (non-numeric) | Higher initial unit cost in some cases, but potential savings in reduced corrosion repair, leakage control and rehabilitation (project-specific). | Lower initial cost in some markets, but potentially higher lifecycle costs in aggressive soil and H₂S conditions without robust protection. | Lifecycle comparisons must include local material pricing, logistics, rehabilitation strategies and service life targets. |

| Limitations / when each is better | Sensitive to handling, point loads and incorrect bedding; needs UV-considered covers and compatible backfill. | Better for very large or very deep shafts, or where cast-in-place is already standard and liners/coatings are specified. | Selection in Saudi Arabia should follow soil/water chemistry, depth, traffic, construction capabilities and AHJ preferences. |

Table 3 – Saudi soil & groundwater data checklist

| What to test | Why it matters | Who usually provides it |

|---|---|---|

| Soil sulfate content (water-soluble) | Drives risk of sulfate attack on concrete; guides cement type or decision to use GRP. | Geotechnical consultant or site investigation contractor. |

| Soil chloride content | Indicates chloride exposure for buried concrete and metals, especially near coasts. | Geotechnical or materials testing laboratory. |

| Groundwater level and fluctuation | Governs external head on joints, flotation risk and infiltration potential. | Geotechnical report and hydrological data. |

| Groundwater salinity and chemistry | Influences corrosion risk for concrete and metal accessories, and compatibility with resins. | Laboratory analysis commissioned by consultant/owner. |

| Sewer H₂S potential (sulfide, BOD, flow) | Indicates risk of MIC and need for corrosion resistant manhole materials and linings. | Sewer designer or process engineer, based on flow data. |

| Industrial or special effluents | Determines whether unusual chemicals could attack concrete, GRP resin or gaskets. | Industrial client, utility operator or environmental consultant. |

FAQs

Q1: Why do concrete manholes fail in Saudi Arabia?

A1: Concrete manholes often fail due to a combination of sulfate-bearing soils, saline groundwater, chloride-induced reinforcement corrosion, and microbiologically induced sulfuric acid attack from sewer H₂S, compounded by cracking and joint leakage. The actual rate and severity vary by site chemistry, design details, protective measures and maintenance. Details

Q2: Are GRP manholes corrosion resistant?

A2: GRP manholes are corrosion resistant to many common sewer and soil environments because they have no steel reinforcement and use resins that can withstand sulfates, chlorides and acidic condensate, especially when a corrosion barrier layer is specified. Compatibility must still be checked against the specific soil, groundwater and any industrial effluents for each project.

Q3: GRP vs concrete manhole: which lasts longer?

A3: In aggressive Saudi soil and H₂S sewer conditions, properly specified GRP systems and well-protected concrete structures can both achieve long service lives, but concrete without suitable protection is more vulnerable to chemical attack and reinforcement corrosion. Actual life expectancy varies by design, materials, installation quality and inspection/rehabilitation practices, so a project-specific life-cycle assessment is required.

Q4: Do GRP manholes work in coastal areas?

A4: Yes, GRP manholes are widely used in coastal environments because they are not susceptible to chloride-induced steel corrosion and can be designed for saline groundwater and airborne salt exposure. For coastal Saudi sites, engineers should still confirm resin and gasket compatibility with local groundwater chemistry and specify corrosion-resistant hardware for frames, steps and fasteners.

Q5: How do watertight joints help?

A5: Watertight joints reduce groundwater infiltration into the sewer system and prevent exfiltration of sewage, which can cause soil fines loss, sinkholes and environmental contamination. In high groundwater or saline aquifers, this also limits dilution of sewage, reduces pumping and treatment costs, and protects surrounding infrastructure.

Q6: Can GRP manholes be used under roads?

A6: GRP manholes can be used under roads in Saudi Arabia when designed for the required traffic load class, with appropriate cover frames, bedding and backfill in accordance with project specifications. Structural design should consider wheel loads, depth of cover and local standards, similar to concrete manholes, and installation quality is critical for long-term performance.

Q7: What causes manholes to leak?

A7: Common causes of leakage include poorly sealed joints, degraded gaskets, shrinkage or thermal cracking, differential settlement and defects at pipe penetrations. Both GRP and concrete manholes can leak if detailing, installation and QA/QC are inadequate, which is why watertightness testing and inspection are important.

Q8: What information do you need for a quotation?

A8: For a GRP manhole Saudi Arabia quotation, suppliers typically need manhole diameter, depth, traffic/loading class, soil and groundwater reports (sulfates, chlorides, salinity, groundwater level), pipe sizes and materials, joint and connection requirements, and any applicable standards or authority requirements. Sharing layout drawings, typical details and any special corrosion or H₂S concerns helps engineers propose the correct corrosion resistant manhole system.

Conclusion

For Saudi and GCC projects, GRP manholes offer clear advantages over traditional concrete in aggressive sulfate, chloride and H₂S environments, especially where leakage control and installation speed are priorities, while concrete remains appropriate for some large or deep structures when properly protected. If you are planning new sewer networks or manhole rehabilitation KSA works, you can review your soil and groundwater reports and then Request a Quote or Talk to our engineers to evaluate which manhole solution best matches your project specifications and authority requirements.