Introduction

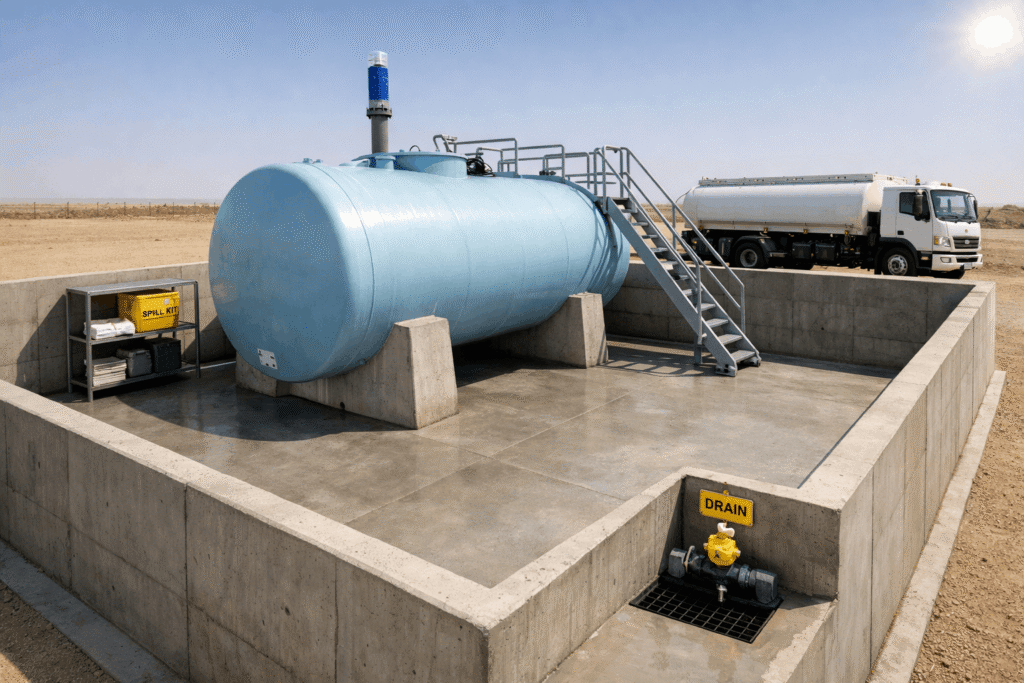

A bund wall diesel tank installation is the last line of defense against spills, soil contamination, and costly shutdowns. A diesel tank spill is not just an operational headache—it is an environmental and legal disaster. In Saudi Arabia, diesel leaking into soil contaminates groundwater, attracts hefty environmental penalties (up to SAR 30 million), and can result in facility closure and imprisonment for responsible parties. A bund wall is the engineered barrier that stops this scenario from happening. It is the last line of defense: if your primary tank fails, the bund catches the fuel before it reaches soil, drains, or waterways.

This guide explains what a bund wall is, why it is critical for diesel storage sites, which design option suits your facility, and how to maintain one properly. All recommendations are grounded in NFPA 30, environmental standards, and Saudi regulatory requirements. Whether you are installing a generator fuel tank, a bulk diesel storage system, or an industrial facility tank, understanding secondary containment is essential.

Quick Answer: 8 Key Points on Bund Walls for Diesel Tanks

- Bund wall is your last line of defense: It catches fuel from leaks, overfills, and equipment failures before they reach the environment. Without it, a small leak becomes a major liability.

- Protects people, environment, and business continuity: Spill = facility shutdown + cleanup cost + fines + reputation damage. A proper bund prevents all of this.

- Helps meet HSE expectations and inspections: Auditors, regulators, and client projects expect secondary containment to be in place and properly maintained. Non-compliance = failed inspections and project delays.

- Prevents stormwater and drain contamination: Diesel must never enter stormwater drains, municipal sewers, or surface water. The bund is your barrier to compliance with environmental regulations.

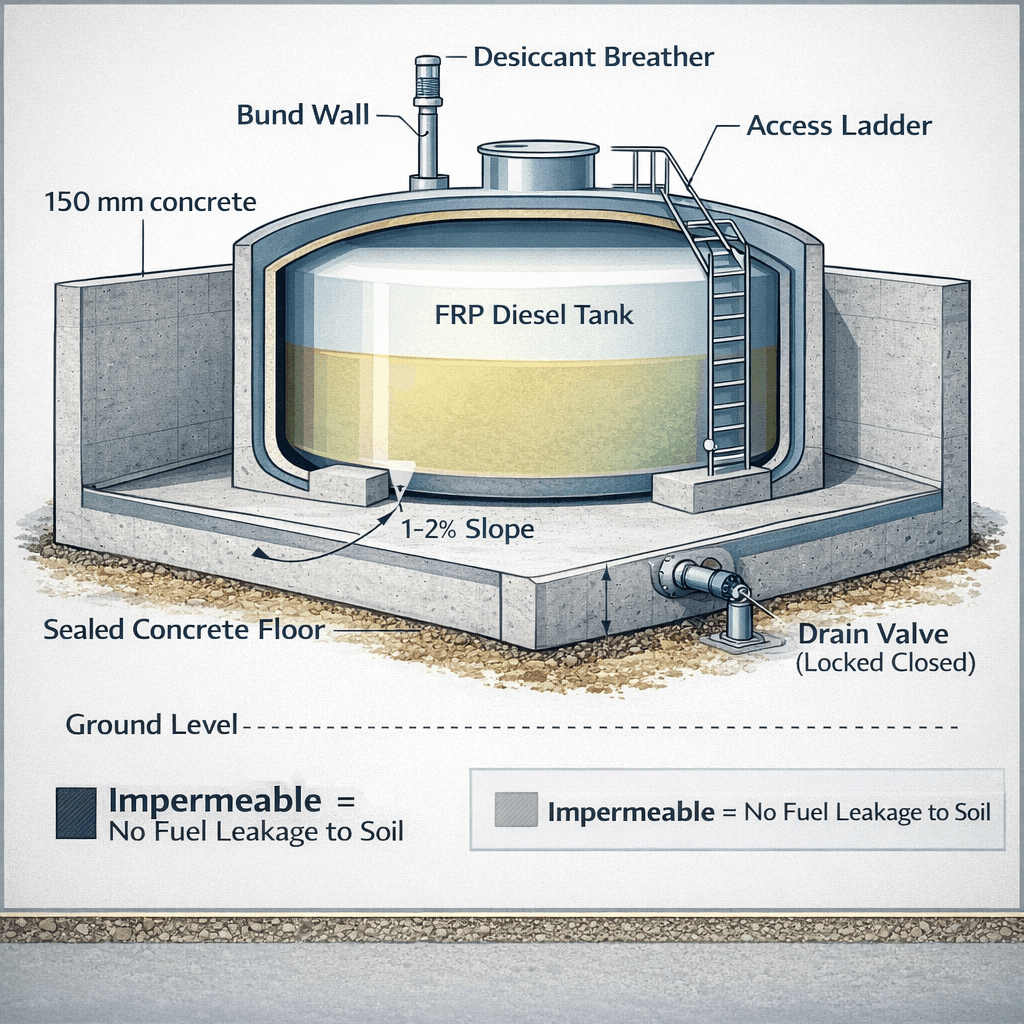

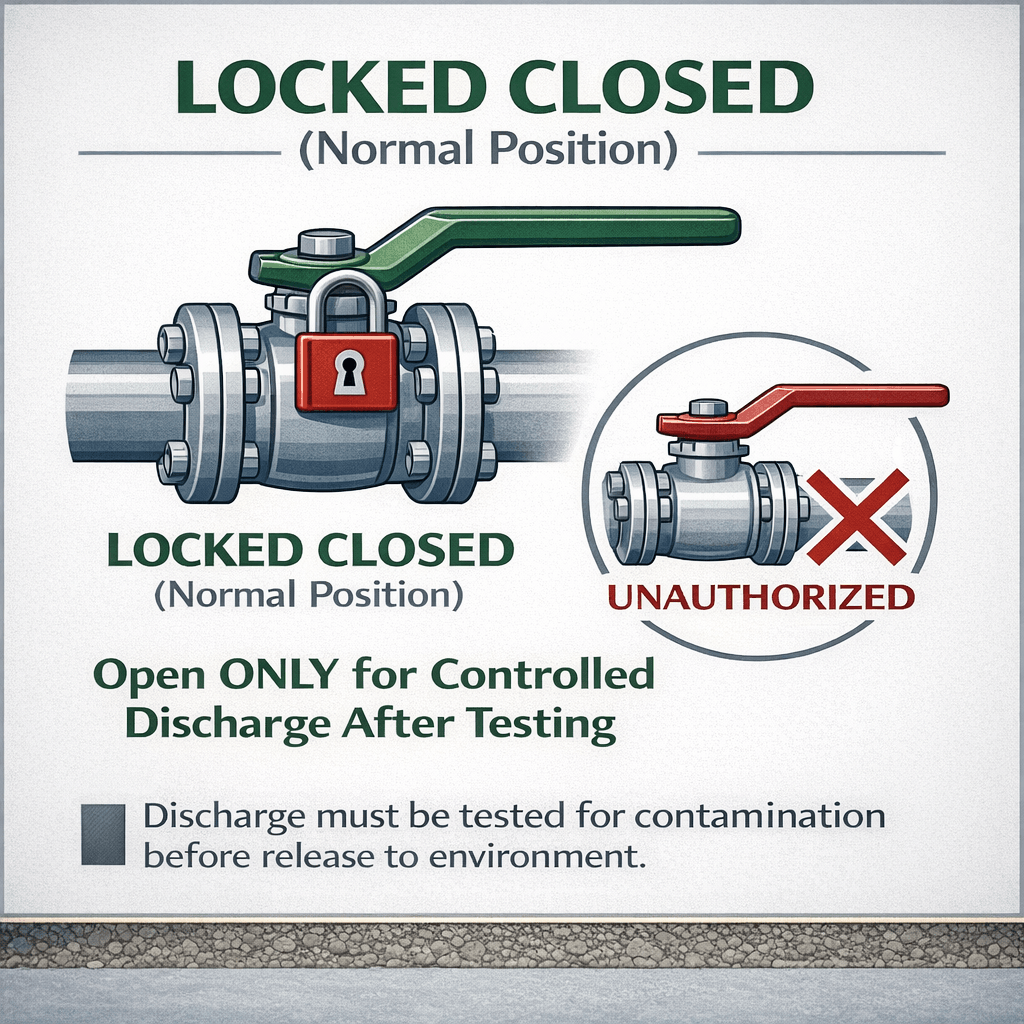

- Bund is more than “just a wall”: It needs a sealed, impermeable base, sloped floor for drainage, controlled drain valve (normally locked closed), sump pit, and regular inspection access. Cutting corners on design = containment failure.

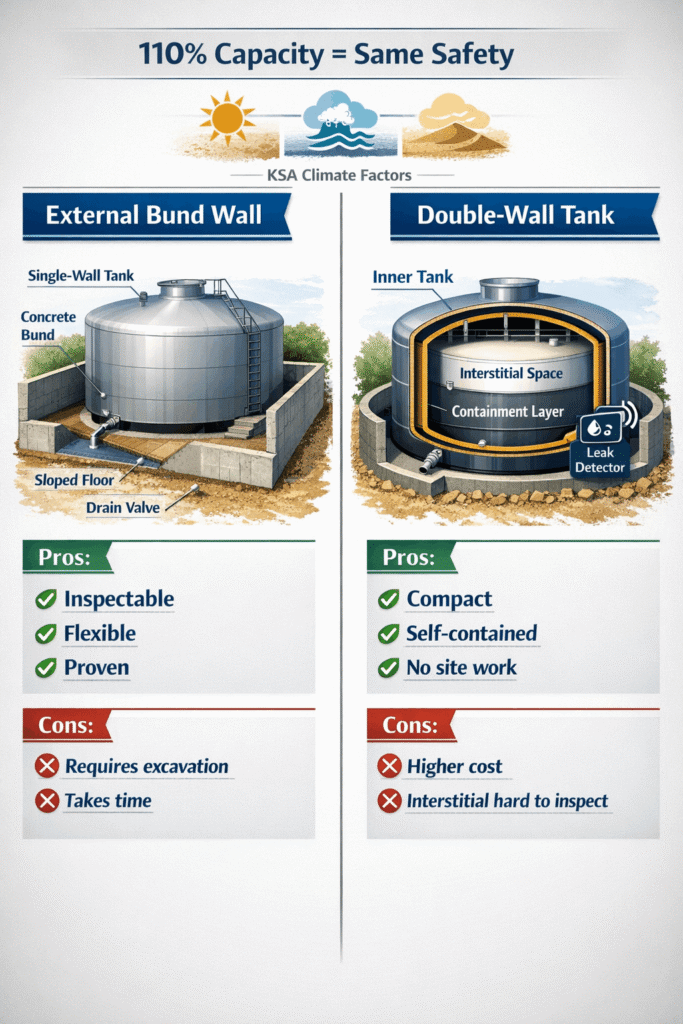

- Choose between external bund vs double-wall tank: Single-wall tank + concrete bund is proven and flexible; double-wall (tank-in-tank) is compact but higher cost. Both meet 110% containment requirement. Choose based on space, budget, and inspection accessibility.

- KSA heat, sand, and coastal salt spray affect design: Unshaded bunds absorb heat; sandy soil requires impermeable liners; salt spray corrodes metal fittings (use stainless steel 316). Site-specific design matters.

- Proper information is needed before design: Tank size, installation location, site soil/drainage, frequency of refueling/delivery, available footprint, local authority requirements, and annual rainfall all shape the bund design.

What Is a Bund Wall / Secondary Containment?

Primary containment = the tank itself. Secondary containment = the engineered system that catches fuel if the primary tank fails.

A bund wall is a physical barrier (typically concrete) surrounding a diesel tank, creating a contained space. If the tank leaks, overflows, or ruptures, the fuel collects in the bund instead of soaking into soil.

Key Components of a Bund System

- Perimeter wall: Reinforced concrete, typically 1–2 meters tall (varies by tank size and design)

- Impermeable floor: Concrete slab with sealed joints, sloped 1–2% toward a sump for drainage

- Sealed penetrations: Pipes, electrical conduits must pass through sealed sleeves; no gaps where fuel can escape

- Drain valve and sump: Located at lowest point. The valve remains locked CLOSED except during controlled drainage after inspection

- Spill containment access: Safe entry steps or ladder for inspection and cleanup

- Freeboard: Extra height in the bund to hold rainwater (typically 6+ inches above tank height)

Key Terms (Simple Definitions)

- Bund: The contained area surrounding a tank; also called a dike or dike wall

- Dike: Earthen or concrete wall forming the bund perimeter

- Secondary containment: Any system (bund, double-wall tank, spill pallet) that holds 110% of primary tank capacity

- Sump: Lowest point in the bund where liquid collects; typically has a valve and pump-out access

- 110% capacity rule: Bund must hold 110% of the largest tank’s volume (e.g., a 10 m³ tank requires an 11 m³ bund)

- Impermeable: Prevents fuel from soaking through; concrete + sealant or HDPE liner

- Freeboard: Vertical clearance above the maximum expected liquid level (accounts for rainfall)

Why Bunding Matters for Diesel Tanks (Real KSA Scenarios)

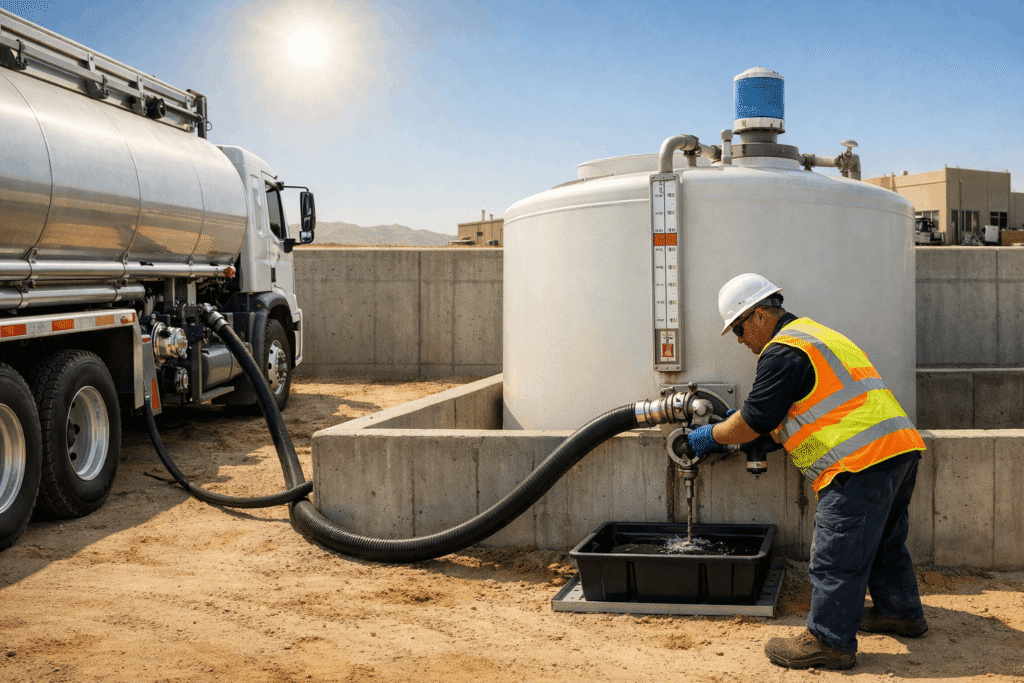

Overfill During Tanker Delivery

A fuel truck is filling your generator’s bulk tank. The driver steps away “for just a moment.” The filling valve jams open. In 15 minutes, 500 liters of diesel overflow from the tank. Without a bund, it spreads across the yard toward the stormwater drain. With a bund, it collects safely in the contained area, waiting for cleanup.

Hose Failure During Refueling

Flexible hoses crack from age, heat, and vibration. A 3 mm split develops where nobody notices. Over 30 days, 100 liters leak silently into the sand beneath the tank. With a bund, the first few liters land on the floor; the spill is discovered quickly. Without a bund, the fuel soaks deep into soil; groundwater contamination detected too late.

Slow Leak from Valve or Flange

A bolted pipe connection weeps diesel at 0.5 liters/day. Over a week, 3–4 liters accumulate. In a non-bunded installation, fuel reaches the soil and drains. In a bunded installation, the puddle is visible on the concrete floor during weekly housekeeping; the leak is fixed before it worsens.

Vandalism or Vehicle Impact

A forklift backs into the tank. A generator vibrates and loosens bolt connections. Heavy rains overflow drainage systems. A bund wall contains these events; without one, spill = soil contamination + legal action.

Rain Event Washing Diesel to Storm Drains

In the rare event of heavy rainfall overwhelming a bund’s drainage system, the accumulated liquid remains trapped inside the bund (not escaping to stormwater). It is pumped out and tested before discharge, per environmental regulations.

Environmental + Legal + Financial Consequences

Environmental Impact

Diesel in soil persists for years. It seeps into groundwater, contaminating drinking water wells and agricultural land. Once groundwater is polluted, remediation costs tens of thousands of SAR and takes months. In coastal areas (Jeddah, Dammam), contaminated groundwater flows toward the sea, affecting marine ecosystems.

Legal and Regulatory Consequences (Saudi Arabia)

Saudi Arabia’s General Environmental Regulations strictly prohibit contamination of soil and water. Penalties for violations:

- Fine: Up to SAR 20–30 million depending on violation severity

- Imprisonment: Up to 5 years for serious violations (Article 35 violations)

- Doubled penalties: Repeat violations within 1 year incur doubled fines and imprisonment

- Mandatory remediation: Violator must eliminate the contamination and pay compensation

- Facility closure: Authorities can close the plant for 90+ days

- License revocation: Operating permits suspended or revoked

A single diesel spill without proper containment can bankrupt a facility through cleanup costs and fines.

Financial Impact (Business Continuity)

- Cleanup cost: SAR 50,000–500,000+ depending on spill volume and soil depth

- Downtime: If diesel reaches the generator fuel supply or spreads to critical equipment, facility shuts down (costly for industries running 24/7)

- Emergency tanker deliveries: If spill contaminates the storage area, temporary portable fuel tanks may be required at high premium cost (SAR 200–500/delivery)

- Regulatory inspections and audits: Non-compliant tanks trigger mandatory inspections, adding delays to projects and operations

- Insurance implications: Liability claims, coverage denials, premium increases

Exact consequences depend on AHJ (Authority Having Jurisdiction) enforcement, client project requirements, and incident severity. Confirm specific penalties with environmental authorities in your region.

Bund Wall vs Double-Wall Tank vs Spill Pallet (Which One?)

Three main secondary containment options exist. Each has distinct advantages and limitations.

Comparison Table

| Solution | Best For | Pros | Limitations | Notes for KSA |

|---|---|---|---|---|

| External bund (concrete wall + sealed floor) | Most industrial diesel installations; flexibility needed; retrofits | Proven design; easy to inspect/clean; can accommodate multiple tanks; low cost per m³; simple repairs | Requires site excavation/preparation; takes time to construct; occupies footprint | Most common in KSA industrial yards. Concrete + HDPE liner handles heat/salt spray well. Simple to expand capacity later. |

| Double-wall tank (tank-in-tank, FRP or steel) | Space-constrained sites; premium environmental protection; new installations | Compact footprint; built-in 110% containment; integrated leak monitoring; easy to move if modular; no site prep needed | Higher upfront cost; interstitial space difficult to inspect; limited capacity range; harder to clean inside bund | FRP double-wall tanks ideal for KSA’s coastal/salty zones (no steel corrosion). Lightweight FRP simplifies transport to remote sites. Leak sensors detect issues early. |

| Portable spill pallet / drip tray | Temporary installations; small tanks (<2,000 L); emergency backup; day tanks near generators | Quick deployment; no site work; low cost; movable | Limited capacity (~500–1,000 L typically); not suitable for bulk storage; frequent manual emptying; rain overflow risk | Used for generator day tanks, portable fuel carriers. Cannot be primary containment for large installations. Not compliant for permanent sites in KSA without supplementary bund. |

What Makes a Bund Actually Work? (Design Essentials)

A bund that looks good on paper but fails in practice often has one or more design gaps. Here are the non-negotiables:

Capacity Principle

Secondary containment must hold 110% of the largest single tank’s maximum capacity. This 10% buffer accounts for fire-fighting foam, rainwater, or surge from rapid fluid discharge. For a single 10 m³ tank, the bund must hold 11 m³ minimum. For multiple tanks, the bund must hold the greater of:

- 110% of the largest tank, OR

- 25% of the total aggregate capacity of all tanks in the same bund

Calculate capacity before construction. Undersized bunds = failed inspections and environmental liability.

Impermeable Base and Lining

The floor of the bund must be impermeable to diesel and water. Options:

- Concrete: 150 mm thick minimum, reinforced with rebar, sealed surface (epoxy coating or polyurethane). Sealed joints at all concrete blocks/seams.

- HDPE (high-density polyethylene) liner: 1.5–2 mm thickness, heat-welded seams (not overlapped). Protects against sandy soil infiltration.

- Composite: Concrete base + HDPE or rubber membrane lining (adds cost but ensures impermeability in difficult soil)

Sand and high water tables in KSA require careful lining design. Consult a geotechnical engineer if soil is permeable or water table is high.

Sealed Penetrations and Joints

Every pipe, electrical conduit, and outlet passing through the bund wall must be sealed with a “sleeved” penetration:

- Pipe passes through a larger diameter sleeve (cast into concrete or installed afterward)

- Sealant (epoxy, polyurethane, or rubber gasket) fills the gap

- No “gaps” where fuel can escape along pipes

Cracked concrete floor or unsealed penetrations = containment failure. Inspect these during commissioning and annually.

Drain Management: Normally Closed, Locked, Controlled

The drain valve at the sump is critical and often mismanaged:

- Position: Always CLOSED except during controlled discharge after inspection

- Lock mechanism: Valve should be sealed with a padlock; only authorized personnel open it

- Discharge procedure: Before draining accumulated water/diesel from the bund:

- Test the liquid (visual, sniff test, or lab analysis)

- Verify it is safe for disposal (no diesel contamination)

- Pump into an approved waste container (not to stormwater)

- Document the discharge (date, volume, test results)

- Re-lock the valve

- Never drain to stormwater: This is a violation of Saudi environmental regulations

Sump Location and Pump-Out Method

The sump is where accumulated liquid collects. Design considerations:

- Location: Lowest point in the bund (confirmed by slope survey)

- Volume: Sized to hold anticipated rainwater + minor spills (e.g., 1–2 m³ for a 50 m² bund in moderate rainfall areas)

- Pump-out method: Manual hand pump, portable electric pump, or submersible pump. Facility must have pump + hoses + trained operator accessible within hours if liquid accumulates

- KSA heat: Sump should be shaded or covered to prevent evaporation of accumulated water (which concentrates diesel residues)

Freeboard Concept

Freeboard is the vertical clearance above the maximum liquid level. It accounts for:

- Rainfall: Bund floor must be sloped; heavy rain may temporarily accumulate. Freeboard ensures overflow does not spill over the wall.

- Tank surge: When fuel is rapidly discharged into the bund (tank failure), liquid level rises; freeboard prevents spillover.

- Typical freeboard: 300–600 mm above the top of the tank is common

KSA considerations: While rainfall is rare, occasional thunderstorms in winter require freeboard. Design accordingly.

Vehicle Impact Protection

In industrial yards where vehicles and forklifts operate, the bund wall is vulnerable to impact:

- Bollards or barriers: Steel posts (diameter 100–150 mm) spaced every 2–3 meters around the bund perimeter, protecting the wall from accidental collision

- Height: Bollards typically 800 mm above ground, 600 mm above the bund wall if wall is elevated

- Cost: Minimal; prevents major wall repair costs

Access for Inspection and Cleanup

The inside of the bund must be accessible:

- Entry steps or ladder: Safe access for personnel to inspect the floor, clean spills, and check drain condition

- Minimum spacing: At least 750 mm between tank and bund wall for walking, visual inspection, and bolt tightening

- Lighting: Bund areas should be well-lit for safe inspection (especially generator areas operating at night)

- Drain access: Sump pump and valve must be reachable without climbing or contorting

Common Bund Failures (What Inspectors Notice)

- Cracked concrete floor, unsealed joints: Small cracks expand under thermal stress (KSA heat) and capillary action. Fuel seeps through to soil beneath the bund.

- Drain valve left open or no lock: Careless maintenance or deliberate abuse. An open drain means the bund is not functioning; any spill escapes directly to soil/stormwater.

- Bund used as storage area: Tools, pallets, old equipment piled in the bund. This reduces available containment volume and obstructs inspection.

- Pipe penetrations not sealed: Pipes running through the bund wall without proper sleeves/gaskets. Fuel follows the pipe to the outside.

- No spill kit visible or accessible: If a small leak occurs, staff have no absorbent materials to contain it. The spill spreads.

- No labeling or hazard identification: Operators don’t know what the tank contains; no emergency contact numbers posted. Response to incidents is delayed.

- No inspection log or maintenance records: Without records, you cannot prove compliance. Auditors and regulators look for logbooks showing regular checks and corrective actions.

- Vehicle impact damage to bund wall: Cracks propagate; structural integrity compromised. Wall may fail to contain a major spill.

- Rainwater pooling in bund (no drainage slope): Stagnant water attracts insects, promotes rust on equipment, and makes inspection difficult.

Operation & Maintenance Best Practices

Bund walls are not “set and forget” infrastructure. Regular care prevents failures.

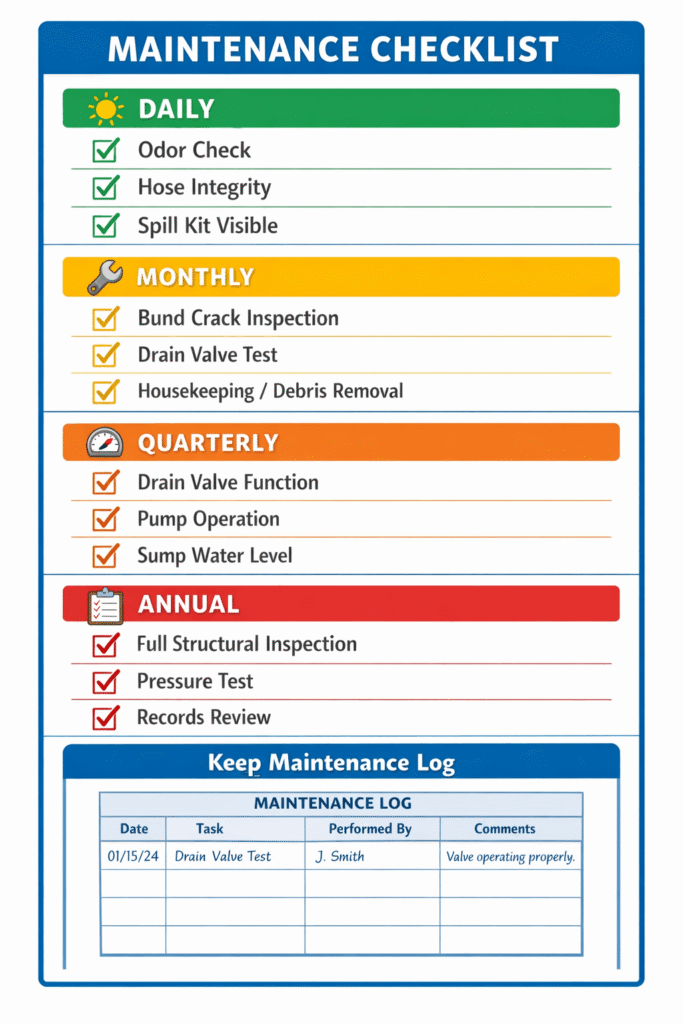

Daily/Weekly Visual Checks (Operator)

- Look for stains or sheen on the floor: Fresh diesel has a distinctive smell and often shows a rainbow sheen on water. Any sign = investigate for leaks

- Check fill connection area: Is fuel splashing? Are hoses intact?

- Verify spill kit is present and accessible: Absorbent pads, sorbent powder, disposal bags should be visible

- Note drain valve position: Is it visibly locked/sealed?

Monthly Housekeeping and Bund Inspection (Maintenance)

- Walk the bund interior: Check for cracks, water pooling, foreign objects

- Test drain valve: Open and close slowly; confirm it operates smoothly and seals completely

- Clean debris: Remove leaves, dust, spilled materials. Keeps inspection area clear

- Inspect bund wall exterior: Look for cracks, rust (on metal fittings), corrosion, vehicle damage

- Photograph any defects: Build a visual record for trending

After Rainfall or Delivery Events

- Inspect for water accumulation: Heavy rain may pool in the bund

- Test the liquid: If water has accumulated, use visual/olfactory test before draining. Do not drain if fuel-contaminated without proper treatment/disposal

- Check for new cracks or seepage: Water infiltration indicates weak spots in concrete

After Each Fuel Delivery

- Inspect for overflow residue: Any spill during filling should be cleaned immediately

- Confirm delivery truck practices: Were hoses inspected? Was overfill alarm functioning? Train drivers on safe procedures

Keep Records

Maintain a simple logbook:

- Date, time, observations, actions taken

- Example: “2026-02-01, 10:00 AM, monthly inspection: no cracks, drain valve sealed, spill kit present and stocked. All OK. Signed: Hassan (Maintenance Tech)”

- Incident log: Any spills, near-misses, or defects discovered (and corrective actions taken)

- Maintenance history: Seal reapplication, bolt tightening, component replacements

Step-by-Step Bund Checklist for Diesel Tank Sites

Use this checklist to ensure compliance from planning through operations.

PLANNING & DESIGN PHASE

- Confirm AHJ (Authority Having Jurisdiction) and client requirements (fire authority, environmental agency, project specifications)

- Identify tank size (capacity in m³) and type (single-wall + bund, or double-wall)

- Confirm installation location: rooftop, ground level, underground? Space constraints?

- Assess site soil conditions: sand, clay, rock? Water table depth? Drainage characteristics?

- Estimate rainfall in your region (affects freeboard/drainage design)

- Identify delivery method: tanker truck with hose, portable cans, pipeline? Frequency?

- Calculate bund capacity required: 110% of largest tank (or 25% total aggregate)

BASE & LINING INSTALLATION

- Clear and level the bund area (survey for slope accuracy)

- Compact soil base to 95% standard Proctor density (geotechnical spec)

- Pour concrete pad: minimum 150 mm thick, reinforced with rebar, sealed surface

- Allow concrete to cure (7+ days) before proceeding

- Install impermeable lining (if HDPE): heat-weld seams, test for leaks

- Slope floor 1–2% toward sump location (critical for drainage)

- Inspect for cracks, holes, protrusions before accepting concrete

DRAIN/SUMP & PENETRATIONS

- Construct sump pit at lowest point: size = 1–2 m³ typical

- Install drain valve with shutoff: ball valve, stainless steel body (coastal sites)

- Provide pump-out access: submersible pump, manual pump, or portable electric pump on-site

- Seal all pipe penetrations with proper sleeved sleeves + epoxy sealant

- Install overflow return line (if applicable for day tanks) back to source tank

TANK INSTALLATION & PIPING

- Position tank on saddle supports, verify level

- Bolt tank down per manufacturer specs; torque fasteners correctly

- Install vent line: 1–2 inch diameter, routed 12+ feet high, desiccant breather

- Install fill connection: elevated, protected, with spill tray beneath

- Install drain: low point, with shutoff valve + check valve

- Connect all fittings and test for leaks (pressure test at 1.5× operating pressure)

SECONDARY CONTAINMENT COMPLETION

- Verify bund capacity math: volume of perimeter × height = at least 110% tank volume

- Complete bund perimeter wall (concrete, bolted panels, or compacted earth + liner)

- Install/verify freeboard: minimum 300 mm above tank top

- Add bollards/barriers if vehicle traffic present

- Construct access stairs/ladder for safe entry

- Test slope: water should flow toward sump without pooling

LABELING + SIGNAGE

- Tank label: “DIESEL” (Arabic + English)

- Hazard label: Flammable liquid symbol (NFPA/ISO)

- Spill kit location sign: “SPILL KIT LOCATION” within 15 m of fill point

- Emergency contact placard: Fire service, facility HSE manager, environmental hotline

- “DO NOT DRAIN TO STORMWATER” sign on drain valve

- Safety Data Sheet (SDS) posted in nearby office

DELIVERY PROCEDURE & TRAINING

- Document safe refueling procedure: steps for fill, overfill prevention, hose inspection

- Train operators/drivers: overfill alarm function, spill kit location, emergency response

- Provide emergency contact list to delivery contractors

- Require written acknowledgment that drivers understand procedures

COMMISSIONING & TESTING

- Hydrostatic pressure test: fill bund with water, inspect for leaks

- Run test for 24 hours; monitor for weeping or cracks

- Functional test: operate drain valve, verify lock mechanism, test pump

- Fill tank; monitor for leaks at all connections

- Test level gauge or sensor for accuracy

- Document all test results and sign-off

ONGOING OPERATIONS

- Establish inspection schedule: daily visual (operator), monthly deep (maintenance), annual formal

- Create and maintain maintenance log

- Schedule annual integrity inspection (pressure test if required by client)

- Review annually after any incident

Common Mistakes to Avoid

- Bund sized too small or sealed poorly. Calculate 110% capacity and verify concrete thickness (150 mm minimum) + sealant before construction. Undersized = failed containment.

- Drain left open to stormwater system. Most common mistake. Drain valve must have a lock; opening it without test/inspection = compliance violation. Never drain contaminated water to stormwater.

- No protection from vehicle impact. Forklifts and trucks damage bund walls; cracks propagate and structural integrity fails. Install bollards if vehicles operate nearby.

- Bund used as storage for tools, pallets, equipment. Reduces available volume; obstructs inspection. Keep the bund empty and clear at all times.

- Pipe penetrations through bund wall not sealed. Fuel follows pipes to the outside. Use sleeved penetrations with proper sealant; inspect regularly.

- No spill kit on-site. If a leak occurs and absorbent materials are not present within 15 m, the spill spreads rapidly. Keep a visible, accessible kit.

- No labels or SDS (Safety Data Sheet). New operators do not know what the tank contains or hazards involved. Label clearly; post SDS.

- No inspection log or maintenance records. Auditors and regulators look for documentation. Maintain a simple logbook showing regular checks and corrective actions.

- No emergency response plan or trained personnel. If a major spill occurs and no procedure is documented, response is chaotic. Write procedures; train staff.

- Ignoring local authority requirements. KSA municipalities and water authorities may have specific local bund/drainage rules. Confirm before design finalization.

- Not considering seasonal conditions. Summer heat accelerates diesel expansion; winter rain affects drainage. Design for your local climate.

- Assuming “double-wall tank” means “no further inspections.” Even double-wall tanks require quarterly-annual monitoring of interstitial space and leak detection systems. Maintenance is non-negotiable.

FAQs

Q1: Do I need a bund wall for a diesel tank?

A: Almost certainly yes. NFPA 30 and most client specifications require secondary containment for diesel storage. Saudi environmental regulations prohibit uncontained fuel storage (fines up to SAR 30 million for violations). Whether you choose an external bund wall or a double-wall tank, secondary containment is mandatory for any commercial/industrial diesel installation in KSA. Confirm your specific AHJ and client requirements before design, but assume secondary containment is required.

Q2: Bund wall vs double-wall tank: what’s the difference?

A: Bund wall = external concrete barrier surrounding a single-wall tank. Proven, flexible, easily inspected. Requires site preparation (excavation, concrete pour).

Double-wall tank = two-layer tank design (primary tank inside secondary containment layer). Compact, no site work needed, higher cost, interstitial space harder to inspect.

Both meet the 110% containment requirement. Choose based on space availability, budget, and inspection accessibility. For most KSA industrial yards, external bunds are more practical. For space-constrained or coastal (salt spray) sites, double-wall FRP tanks excel.

Q3: How do I drain rainwater from a bund safely?

A: Do NOT drain without inspection:

- Monitor rainwater accumulation in the bund

- Before opening the drain valve, test the liquid: Does it smell like diesel? Is there a sheen on the water?

- If contaminated (smells like fuel), treat it as hazardous waste. Pump into a container; dispose via licensed waste handler

- If clean (water only), you can drain it, but route it to:

- A municipal stormwater system (only if local authority permits)

- A temporary holding tank for safe discharge

- Never directly to soil or surface water

- Always lock the drain valve closed after discharge

- Document the drainage event in your logbook

Q4: What should bund floors be made of?

A: Concrete is standard in KSA. Minimum 150 mm thick, reinforced with rebar, sealed surface (epoxy coating or polyurethane). Joints between concrete sections must be sealed.

For sandy soils or high water tables, install an additional HDPE (plastic) liner below or within the concrete to prevent fuel infiltration into soil.

Coastal sites (salt spray exposure): Concrete is fine; ensure metal fasteners/drains are stainless steel (316) to resist corrosion.

Never use unprepared earth as the bund floor. Diesel soaks through sand and clay; groundwater contamination results.

Q5: Can I store equipment inside the bund area?

A: No. The bund is for containing fuel spills only. Storing tools, spare parts, pallets, or other equipment:

- Reduces available containment volume

- Obstructs visual inspection of the floor

- Creates tripping hazards

- May damage equipment if fuel spills

Keep the bund empty and clear at all times. Maintenance personnel need safe access for inspection and cleanup.

Q6: What is secondary containment for diesel?

A: Secondary containment = any system designed to catch fuel from the primary tank if it leaks or overflows. Options include:

- Bund wall: Concrete perimeter + sealed floor surrounding tank

- Double-wall tank: Integrated secondary layer inside tank structure

- Portable spill pallet: Temporary drip tray for small tanks (<2,000 L)

The rule: Secondary containment must hold 110% of the largest tank capacity. This means if your tank is 10 m³, the containment must hold 11 m³. The extra 10% accounts for fire-fighting foam, rainwater, or surge from rapid discharge.

Q7: How often should I inspect a bund wall?

A: Recommended schedule:

- Daily/weekly: Operator visual check (any spills, stains, drain valve sealed?)

- Monthly: Maintenance walkdown (cracks, water pooling, spill kit restocked)

- Quarterly: Functional test (drain valve operates, sump pump works)

- Annually: Formal integrity inspection (concrete surface testing, pressure test if client requires, full documentation)

- After any incident or heavy rainfall: Additional inspection to verify no damage

Keep a logbook of all inspections. Documentation proves compliance to auditors and regulators.

Q8: Does KSA heat change bund design?

A: Yes, indirectly. Saudi summer heat (45–50°C+) does not directly change bund capacity math, but it affects:

- Diesel expansion: Proper venting of the tank prevents overpressurization (not the bund’s role, but related)

- Concrete aging: High heat accelerates concrete deterioration; reapply sealant every 3–5 years instead of 5–7 years

- Water evaporation in sump: Rainwater accumulated in the bund evaporates faster in heat, which can concentrate diesel residues. Keep sump shaded or covered

- Corrosion of metal fittings: Use stainless steel (316) for valves and fasteners in direct sun; mild steel corrodes quickly in KSA heat

- Thermal stress on lining: HDPE liners expand/contract with temperature; seams may weaken. Inspect regularly

Design for KSA climate: specify UV-protective concrete coatings, stainless fasteners, and thermally resistant liners.

Conclusion

A bund wall or secondary containment system is the engineered barrier between a diesel spill and environmental disaster. It is not optional in Saudi Arabia—it is legally required under environmental regulations, demanded by clients and auditors, and essential for protecting your facility’s license and reputation.

Three core principles:

- 110% containment capacity: Always. Non-negotiable.

- Impermeable base + controlled drainage: Fuel stays contained; discharge is tested and authorized before release.

- Regular inspection and maintenance: Even the best-designed bund fails if neglected. Keep logbooks, test drains, and fix cracks promptly.

Whether you choose an external concrete bund or a double-wall tank design, the goal is identical: catching fuel before it reaches the environment. In KSA’s regulatory climate, this investment protects you from SAR 20–30 million fines, facility closure, and imprisonment for responsible parties.

Call to Action

Bund wall and secondary containment systems are critical safety infrastructure. If you are designing or upgrading a diesel tank installation in Saudi Arabia, Pioneers Fiberglass Co. Ltd. can help you select the right containment approach and ensure compliance with NFPA, SASO, and local authority requirements.

Request a Quote for a diesel tank system with proper secondary containment. Provide site details (tank capacity, location, available space, soil conditions, local rainfall patterns) and we will design a compliant bund system tailored to KSA conditions.

Talk to Our Engineers if you have questions about bund sizing, drainage design, material selection for coastal/high-heat environments, or how to document compliance for inspections.

TABLES (All Tables Summary)

Table 1: Bund Configuration Comparison

| Configuration | Best For | Pros | Limitations | KSA Notes |

|---|---|---|---|---|

| External bund (concrete wall + sealed floor) | Most industrial diesel installations; flexibility needed; retrofits | Proven design; easy to inspect/clean; can accommodate multiple tanks; low cost per m³; simple repairs | Requires site excavation/preparation; takes time to construct; occupies footprint | Most common in KSA industrial yards. Concrete + HDPE liner handles heat/salt spray well. Simple to expand capacity later. |

| Double-wall tank (tank-in-tank, FRP or steel) | Space-constrained sites; premium environmental protection; new installations | Compact footprint; built-in 110% containment; integrated leak monitoring; easy to move if modular; no site prep needed | Higher upfront cost; interstitial space difficult to inspect; limited capacity range; harder to clean inside bund | FRP double-wall tanks ideal for KSA’s coastal/salty zones (no steel corrosion). Lightweight FRP simplifies transport to remote sites. Leak sensors detect issues early. |

| Portable spill pallet / drip tray | Temporary installations; small tanks (<2,000 L); emergency backup; day tanks near generators | Quick deployment; no site work; low cost; movable | Limited capacity (~500–1,000 L typically); not suitable for bulk storage; frequent manual emptying; rain overflow risk | Used for generator day tanks, portable fuel carriers. Cannot be primary containment for large installations. Not compliant for permanent sites in KSA without supplementary bund. |

Table 2: Bund Floor Material Options and KSA Suitability

| Material | Impermeability | Cost | KSA Climate Suitability | Maintenance | Best Used When |

|---|---|---|---|---|---|

| Concrete (150 mm, sealed) | Excellent if sealed properly | Low to medium | Excellent; withstands heat. Reseal every 3–5 years | Reapply epoxy/polyurethane coating periodically | Standard choice in KSA industrial yards |

| Concrete + HDPE liner | Excellent | Medium | Excellent; provides redundancy against fuel infiltration | Inspect welds annually; repair tears immediately | Sandy soils or high water table areas |

| HDPE liner only (earth bund beneath) | Good (depends on weld quality) | Medium | Adequate; liners age in KSA heat; requires shade/cover | Heat-weld seams every 5 years; watch for tears | Space-constrained; no room for concrete base |

| Compacted earth + clay membrane | Fair (depends on clay integrity) | Low | Poor in KSA (dry climate = clay cracking); not recommended | Frequent inspection; cracks develop quickly | Not recommended for permanent diesel installations |